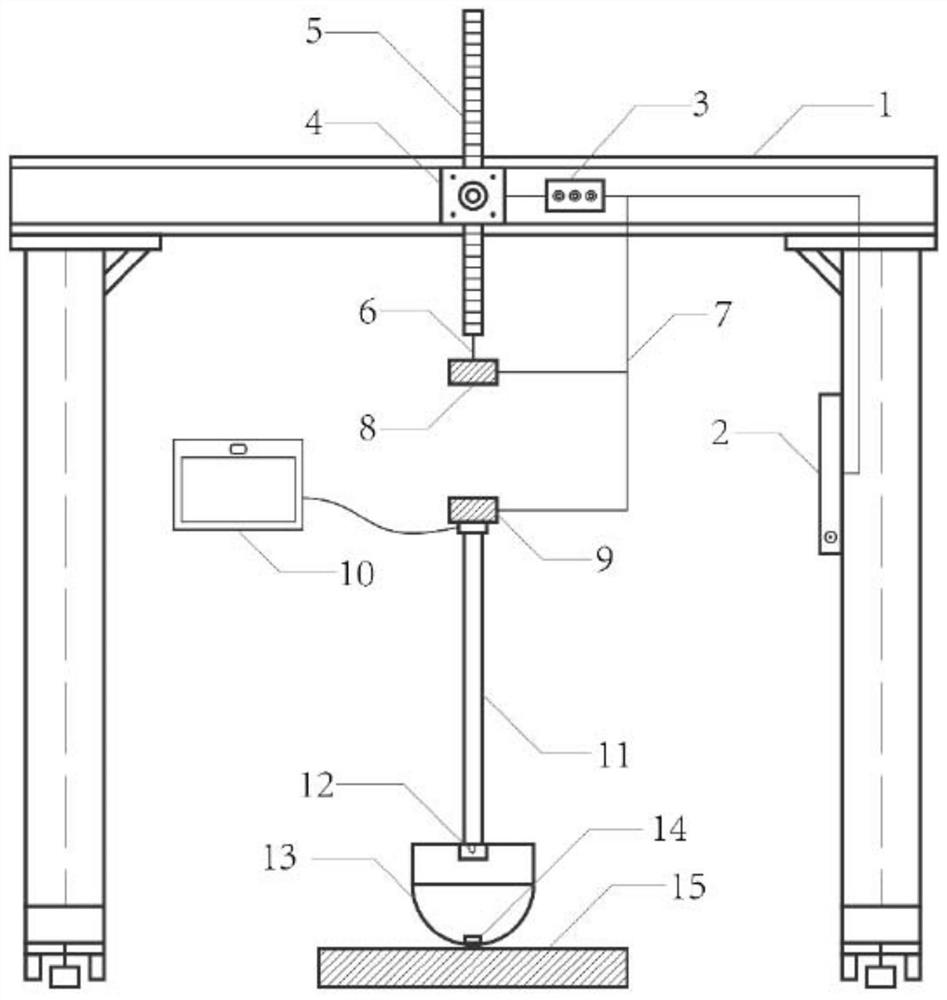

Falling ball type rebound modulus tester

A technology of resilience modulus and tester, applied in the direction of testing material hardness, instruments, measuring devices, etc., can solve the problems of large manual operation error, increased measurement error, smashing and other problems, so as to improve the quality of soil foundation construction and eliminate measurement Error, improve the effect of measurement measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

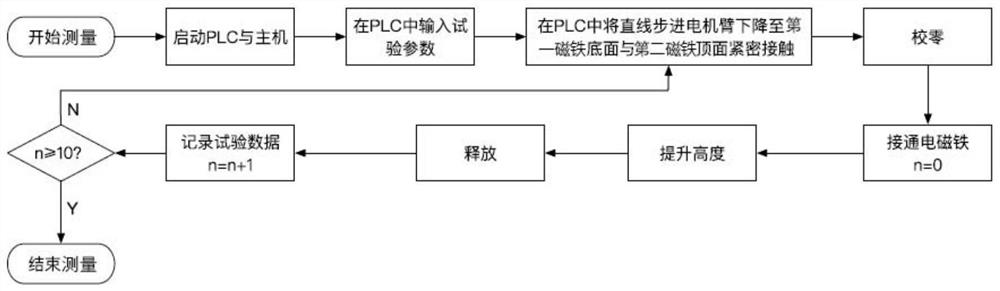

[0032] The falling ball elastic modulus tester is composed of a flange handle, a spherical crown, a host, a time difference measuring device TDC-GP2 and an acceleration sensor. The upper end of the flange handle is connected to the host, and the lower end is connected to the spherical crown. There are acceleration sensor and time difference meter TDC-GP2. When the spherical crown freely falls into contact with the soil-based material, the mechanical response parameters of its impact and collision are sent back to the host connected to the flange handle through the acceleration sensor. When the falling sphere touches the soil-based material, the time difference measuring device TDC-GP2 starts Send a pulse signal, the rebound process is over, and when the falling ball returns to the position where it initially contacts the soil foundation material, the time difference measuring device TDC-GP2 stops measuring and sends the time difference of the rebound process back to the host, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com