Pin adjusting mechanism and method for thin-film capacitor

A film capacitor and foot block technology, applied in film/thick film capacitors, parts of fixed capacitors, capacitors, etc., can solve the problems of uneven processing accuracy of pins, cumbersome steps for pressing and aligning pins, etc., and improve handling efficiency. , good protection, the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

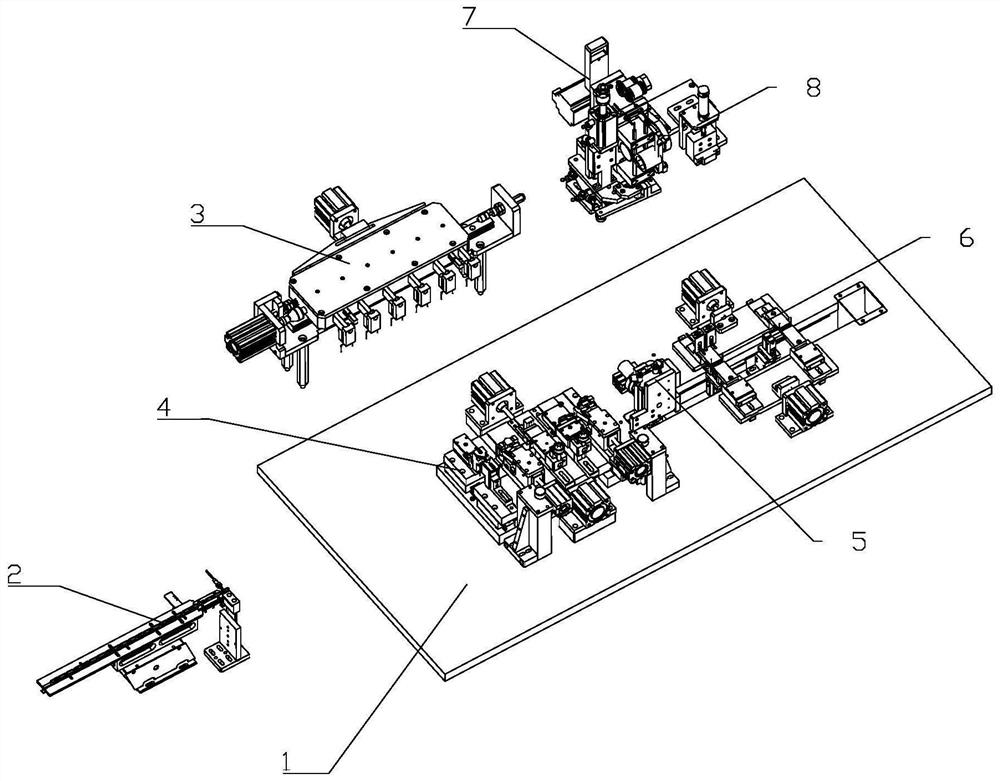

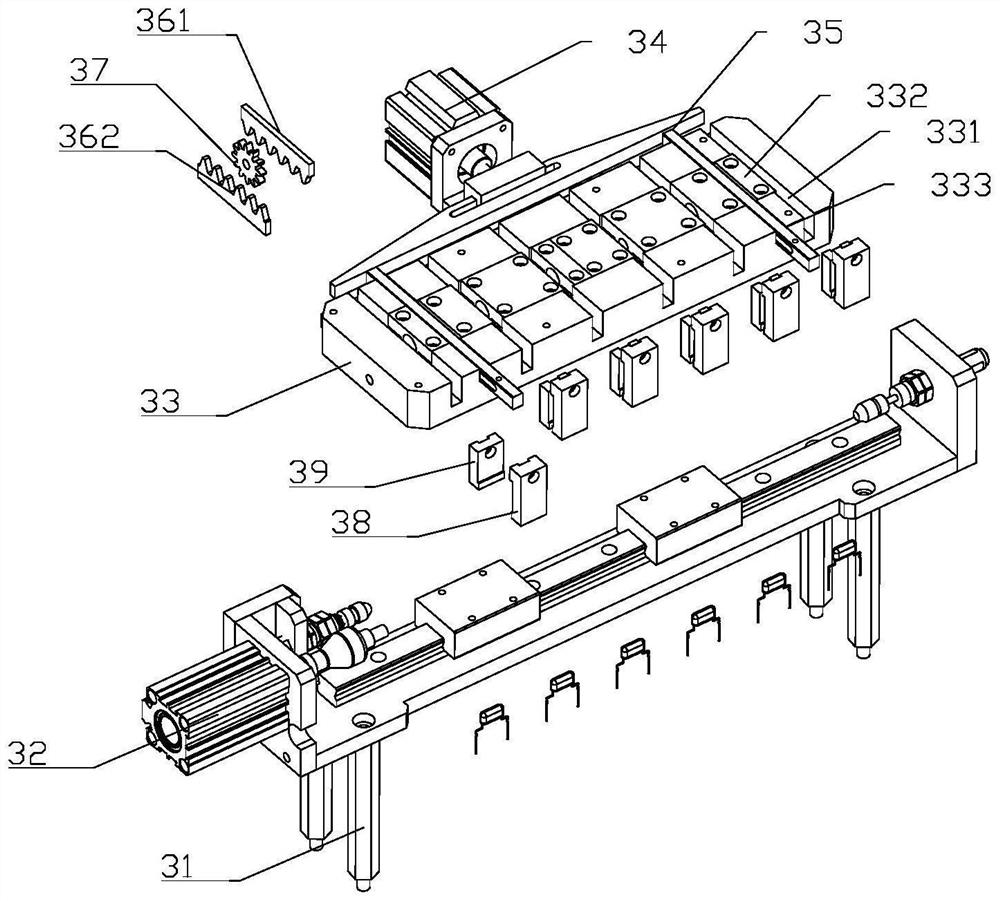

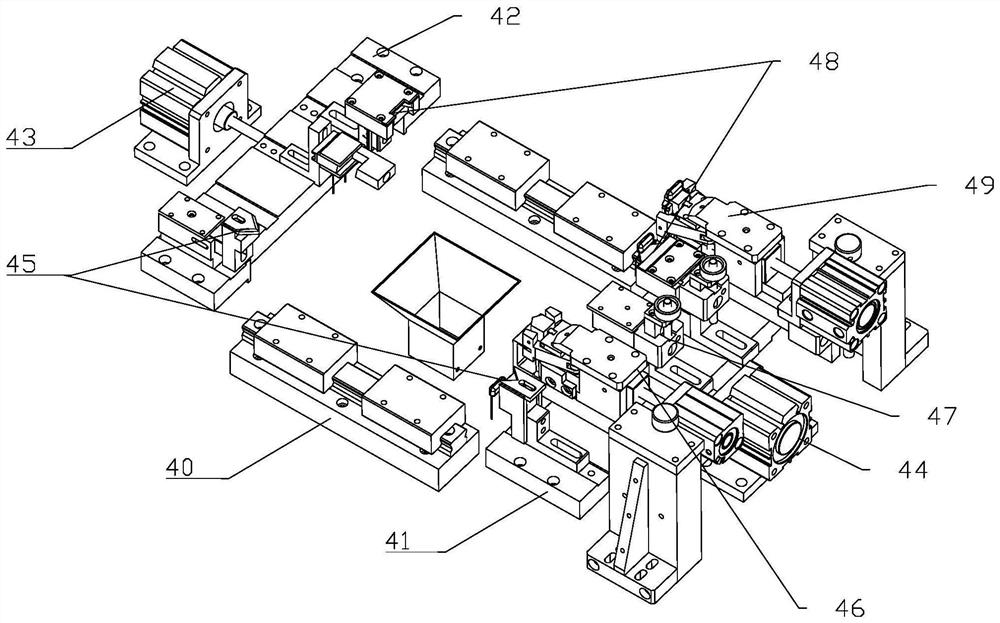

[0036] Such as figure 1 As shown, a film capacitor production equipment includes a frame 1 and a feed conveying device 2 installed on the frame 1, a clamping and transferring device 3, a multifunctional forming device 4, a rotating material turning device 5, and an inversion conveying device 6. The pipe threading device 7 and the pipe pressing device 8; the feeding and conveying device 2 is connected with the clamping and transporting device 3, and the multifunctional forming device 4 is located below the clamping and transporting device 3; the rotating material turning device 5 will The multi-functional molding device 4 is connected to the flip-chip conveying device 6; the pipe threading device 7 and the tube pressing device 8 are located above the flip-chip conveying device 6, and the frame 1 is also provided with a blanking barrel, and the blanking The bucket is connected with the discharge side of the inverted conveying device 6, and the frame 1 is also provided with a ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com