A kind of lycopene coloring agent with fresh-keeping function and its preparation method and application

A technology of lycopene and coloring agent, applied in application, chemical instruments and methods, organic dyes, etc., can solve the problems of poor color rendering effect, inconspicuous effect, poor effect, etc., achieve bright colors, increase shelf life, strong tinting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment provides a lycopene colorant, the raw material of which is composed of: 25 g of lycopene crystals, 100 g of sucrose monostearate, 50 g of phospholipids, 5 g of vitamin E, 620 g of glycerin, and 200 g of water.

[0027] The present embodiment further provides the preparation method of the lycopene colorant, specifically:

[0028] (1) adding each raw material into an emulsification tank, heating to 45°C, shearing and emulsification for 30min under the condition of 6000 rev / min, to obtain an emulsion suspension;

[0029] (2) The emulsion suspension is put into a grinding machine for grinding, and the grinding temperature is controlled to be 40° C., the grinding linear speed is 12 m / s, and the grinding is performed for 120 min.

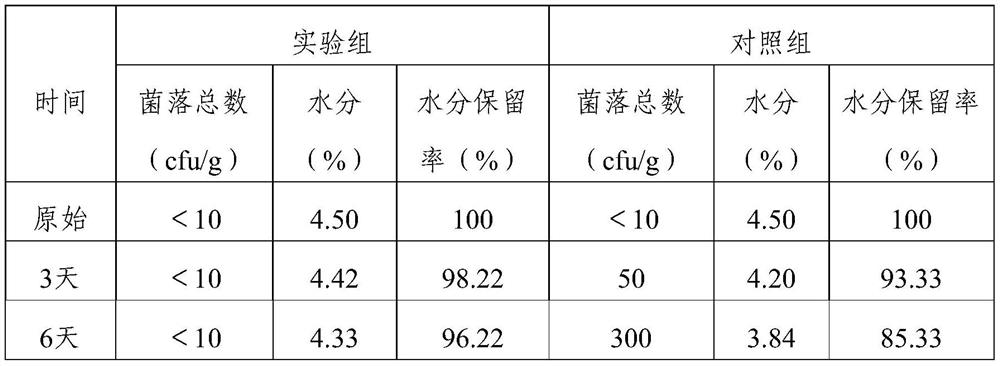

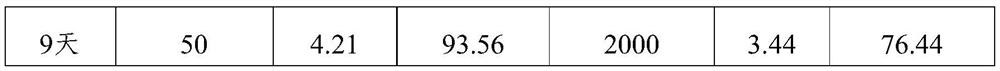

[0030] After testing, the D of the lycopene food coloring agent provided by the present embodiment 50 is 0.58 μm; the hue values are L*35, a*30, b*20 respectively; under the conditions of 25° C. and 60% relative humidity, the vis...

Embodiment 2

[0032] This embodiment provides a lycopene colorant, the raw material of which is composed of: 300 g of lycopene crystals, 801.1 kg of Tween, 100 g of phospholipids, 500 g of tea polyphenols, 7 kg of glycerin, and 1 kg of water.

[0033] The present embodiment further provides the preparation method of the lycopene colorant, specifically:

[0034] (1) adding each raw material to the emulsification tank, heating to 75°C, shearing and emulsification for 15min under the condition of 8000 rev / min, to obtain an emulsion suspension;

[0035] (2) The emulsion suspension is put into a grinding machine for grinding, and the grinding temperature is controlled to be 50° C., the grinding linear speed is 8 m / s, and the grinding is performed for 150 min.

[0036] After testing, the D of the lycopene food coloring agent provided by the present embodiment 50 is 0.65 μm; the hue values are L*30, a*32, b*22 respectively; under the conditions of 25° C. and 60% relative humidity, the viscosity...

Embodiment 3

[0038]This embodiment provides a lycopene colorant, the raw material of which is composed of 1 kg of lycopene crystals, 15 kg of sucrose monopalmitate, 2.5 kg of phospholipids, 3 kg of ascorbic acid, 63.5 kg of glycerin, and 15 kg of water.

[0039] The present embodiment further provides the preparation method of the lycopene colorant, specifically:

[0040] (1) adding each raw material into an emulsification tank, heating to 60 ° C, shearing and emulsification for 45 min under the condition of 7000 rev / min, to obtain an emulsion suspension;

[0041] (2) The emulsion suspension is put into a grinding machine for grinding, and the grinding temperature is controlled to be 60° C., the grinding linear speed is 15 m / s, and the grinding is performed for 120 min.

[0042] After testing, the D of the lycopene food coloring agent provided by the present embodiment 50 is 0.55 μm; the hue values are L*25, a*35, b*25 respectively; under the conditions of 25° C. and 60% relative humidi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com