Dual-mode double-sided automatic scraping and washing pre-filter and washing method thereof

A pre-filter, dual-mode technology, applied in fixed filter element filters, chemical instruments and methods, filtration separation, etc., can solve the cumbersome removal and washing of filter screens and filter cups, small water flow into filter elements, and secondary pollution of water quality And other problems, to achieve good cleaning effect, energy saving, shorten the life of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

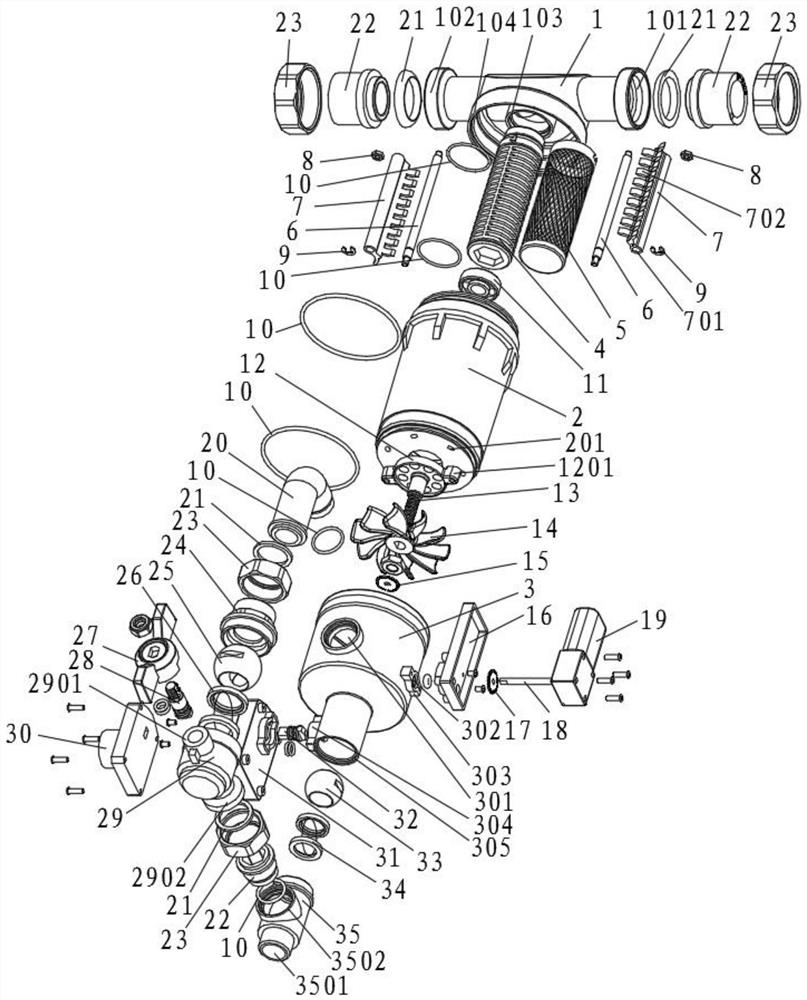

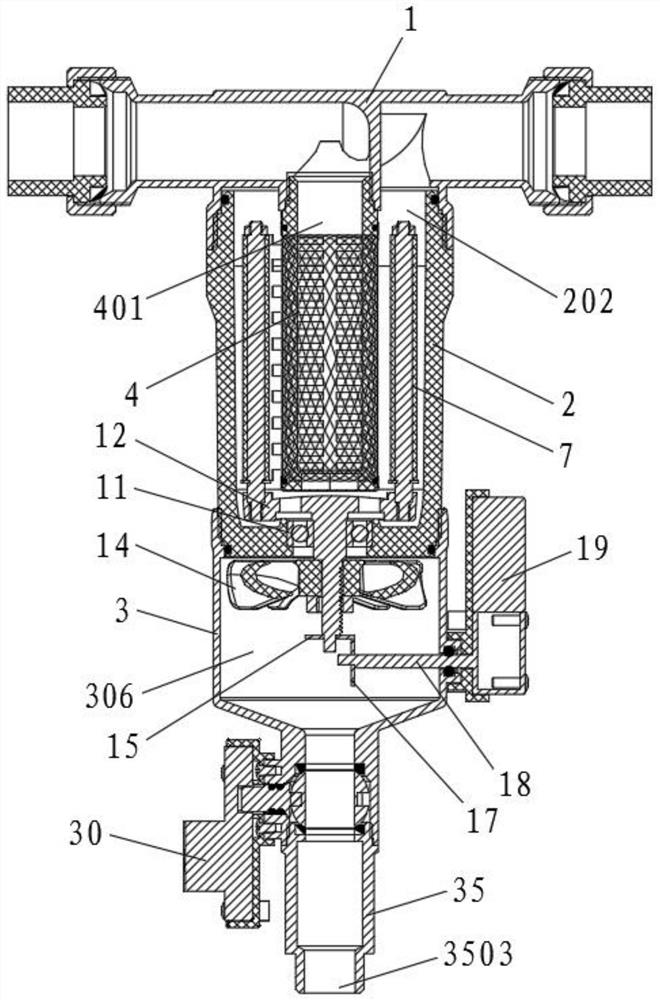

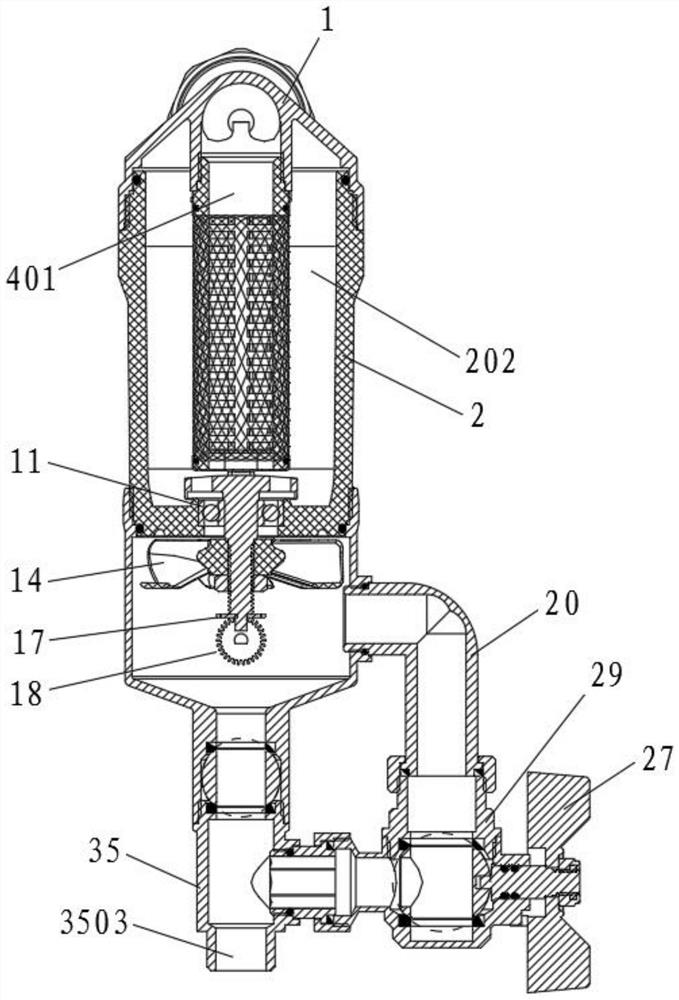

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0024] Such as Figure 1-4As shown, a pre-filter with double-mode double-sided automatic scraping and washing includes an upper valve body 1 and a lower valve body 2, and the two ends of the upper valve body 1 are respectively provided with a source water inlet 101 and a clean water outlet 102, The middle part of the upper valve body 1 is provided with a filter element interface 103 and a filter cup interface 104, the filter element interface 103 is provided with a filter element 4, the inner cavity of the filter element 4 communicates with the clean water outlet 102, and the surface of the filter element 4 is provided with a filter net 5, and The filter cup 2 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com