Powder grinding device for producing medium-ash antirust pigment

A technology of anti-rust pigments and grinding powder, which is applied in grain processing, etc., can solve the problems of low applicability and inconvenient use, and achieve the effects of convenient use, reduced production costs, and convenient operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

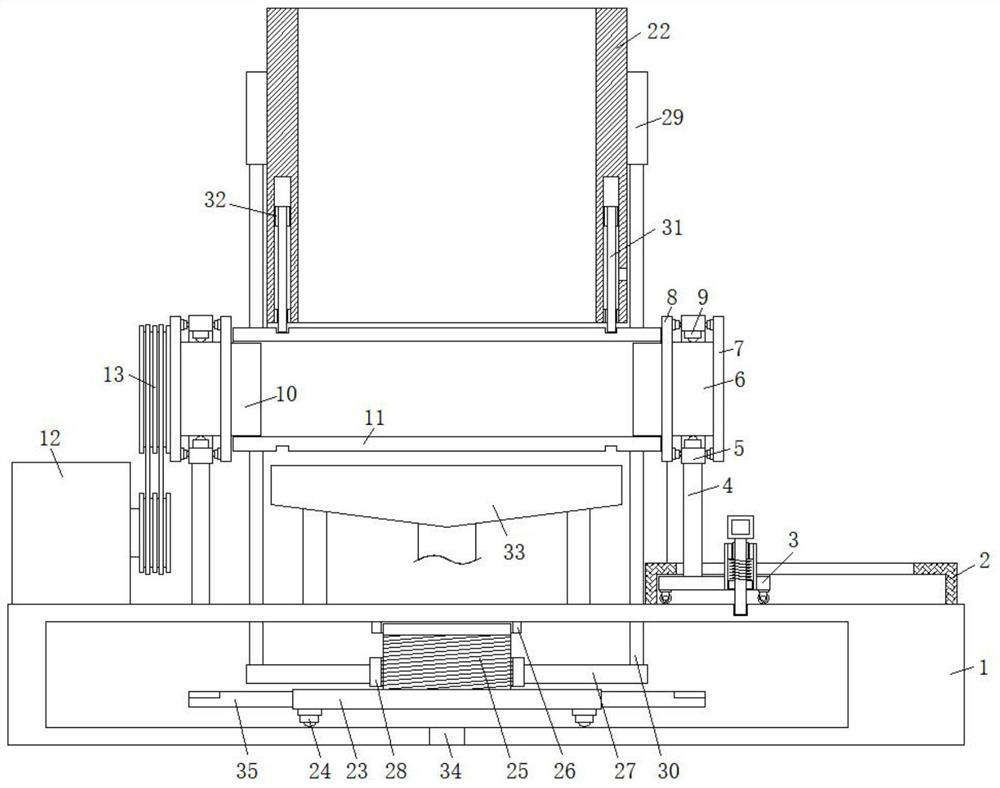

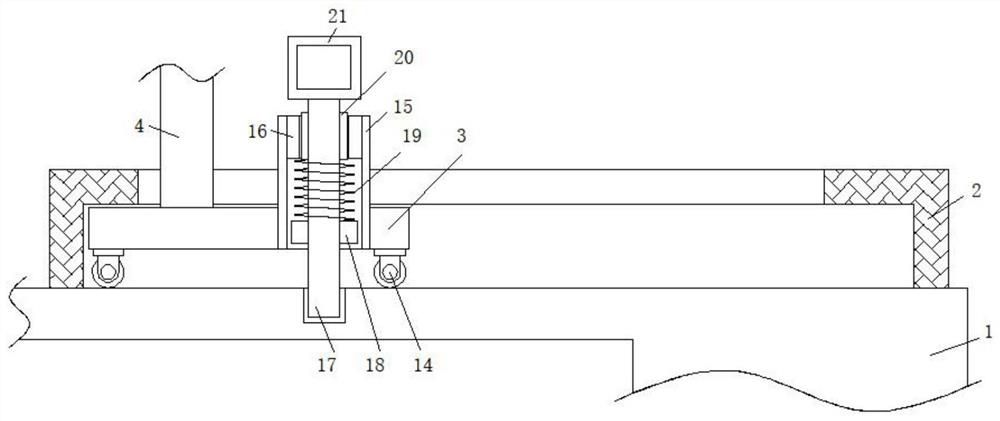

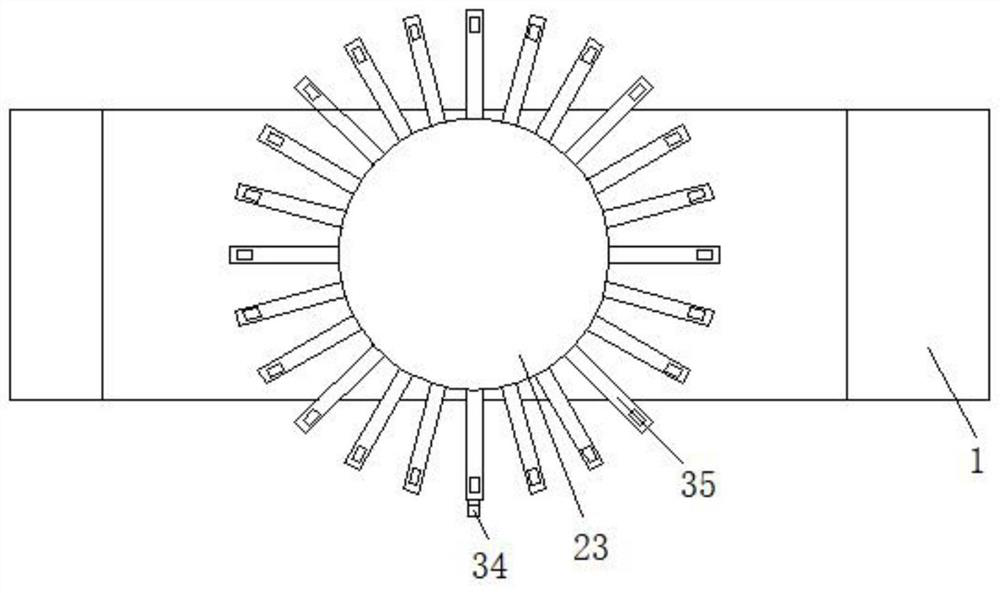

[0028] refer to Figure 1-6 A milling device for producing medium gray antirust pigments, comprising a base 1, a sliding seat 2 is fixedly connected to the top side of the base 1, a slide plate 3 is slidably connected in the slide seat 2, and the base 1 on the top side of the slide plate 3 The top is respectively fixedly connected with a vertical rod 4, the top of the vertical rod 4 is fixedly connected with a vertical ring 5, the vertical ring 5 is rotatably connected with a rotating central shaft 6, and the two ends of the rotating central shaft 6 are respectively fixedly connected with a circular side plate-7 and Round side plate two 8, one side of round side plate two 8 is fixedly connected with polygonal horizontal column 10, and the vertical top of base 1 is provided with milling cylinder 11, and the inwall of milling cylinder 11 is polygonal structure, and the inner wall of milling cylinder 11 The two ends are respectively sleeved on the outside of the cylinder of the p...

Embodiment 2

[0031] Such as Figure 1-6 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the feed boxes 22 have a rectangular box-shaped structure, and the bottom of the feed box 22 is an open structure.

[0032] In this embodiment, the raw material blocks are in contact with the grinding cylinder 11 at the bottom end of the feeding box 22 and undergo grinding processing.

Embodiment 3

[0034] Such as Figure 1-6 As shown, this embodiment is basically the same as Embodiment 1. Preferably, between the round side plate 1 7 and the round side plate 2 8 and the vertical ring 5, and between the inner side of the vertical ring 5 and the rotating central axis 6, there are respectively installed Several wear-reducing balls 9.

[0035] In this embodiment, the arrangement of the anti-friction balls 9 reduces the frictional force of the grinding cylinder 11 during rotation, reduces energy consumption, and improves energy efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com