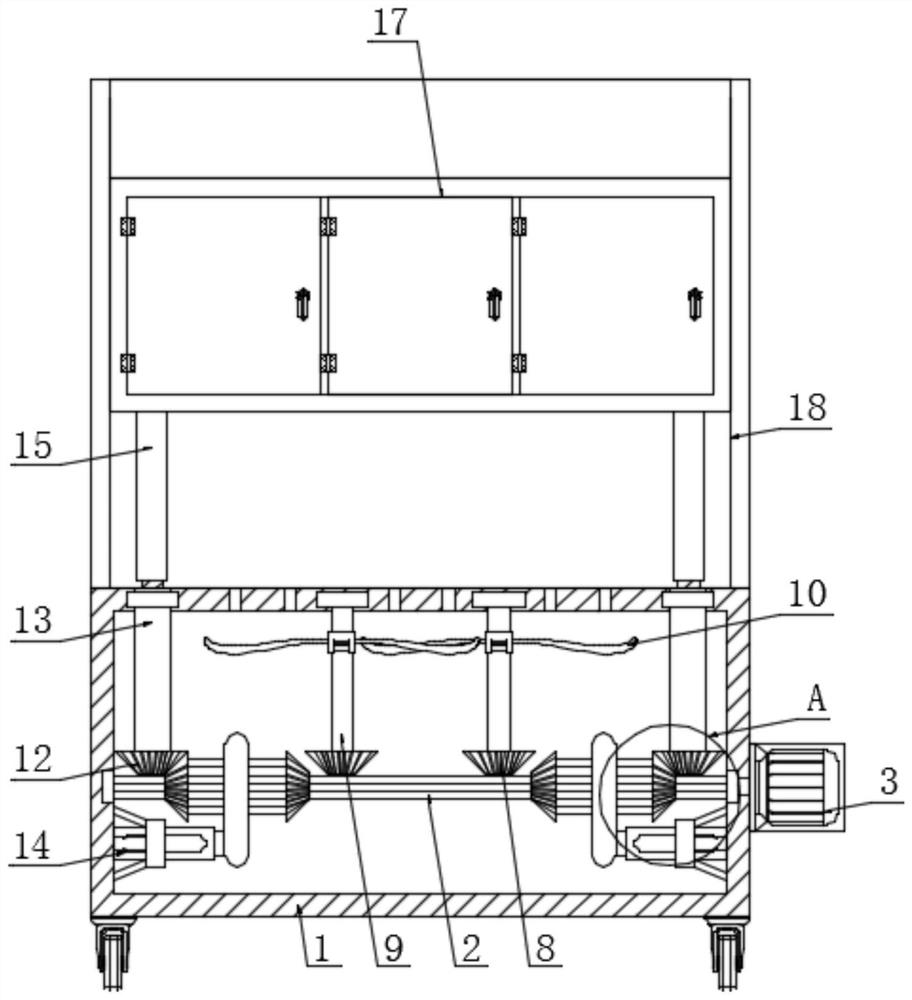

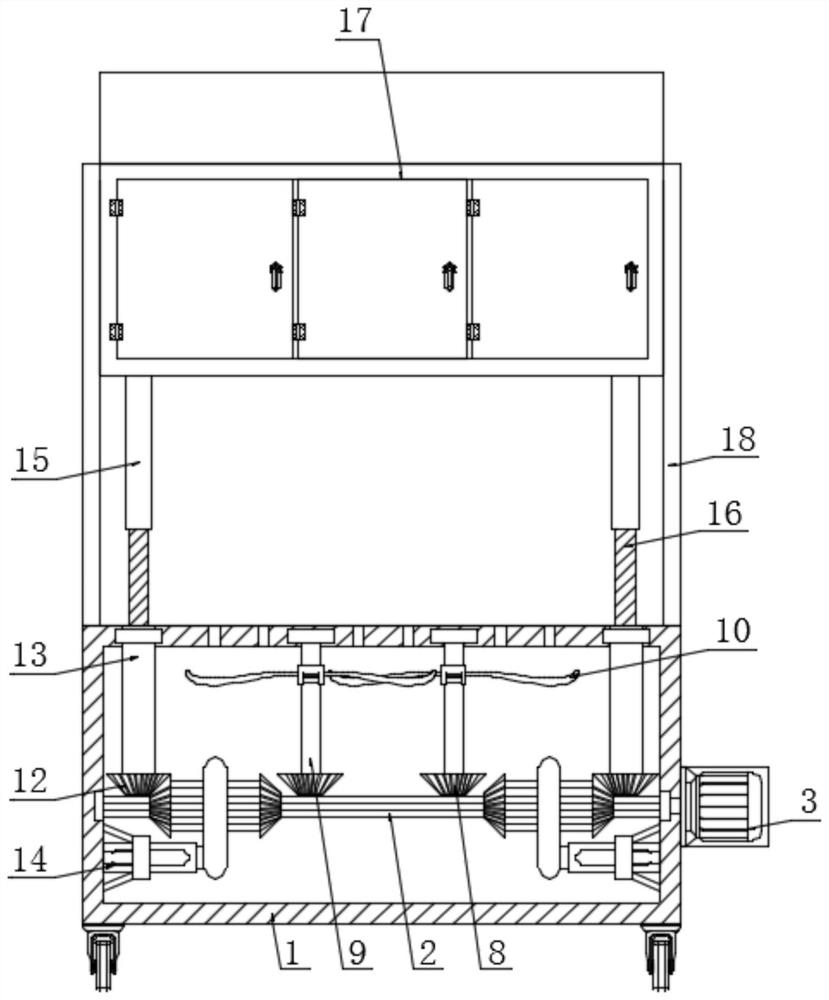

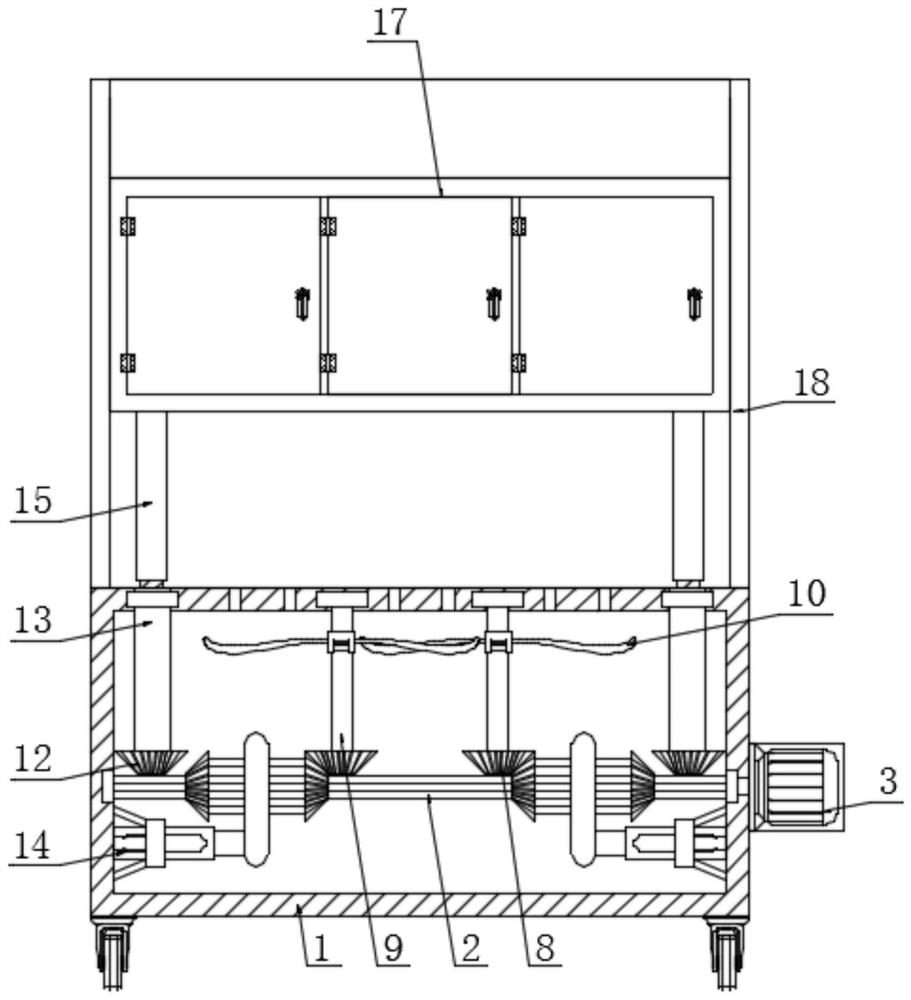

New laboratory fume hood

A laboratory and fume hood technology, applied in the field of laboratory exhaust, can solve the problems of poor ventilation effect of fume hoods, high production and use costs, inconvenient adjustment and use, etc., and achieves fast ventilation speed, low production and use costs, convenient Adjust the effect used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: The workbench 1 is placed horizontally through universal wheels, and the experimental items can be placed in the storage cabinet 17. The fan 19, the motor 3 and the electric push rod 14 are electrically connected to the external distribution box through cables. When in use, control two The electric push rod 14 runs, and the electric push rod 14 drives the two adjustment plates 4 to move to both sides of the shaft rod 2, so that the two second driving bevel gears 6 mesh with the two second driven bevel gears 12. At this time, the control The motor 3 runs, the motor 3 drives the shaft rod 2 to rotate, the shaft rod 2 drives the two second driving bevel gears 6 to rotate, the two second driving bevel gears 6 rotate through the two second driven bevel gears 12, and the two second driving bevel gears 6 rotate. The driven bevel gear 12 drives the two rotating cylinders 13 to rotate. Since the screw rod 16 is threadedly connected with the rotating cylinder 13, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com