Waterproof, bonding and joint filling three-in-one mortar and preparation method thereof

A three-in-one, bonding technology, applied in the field of building materials, can solve the problems of high rigidity of pure water mortar and cement mortar, high plasticity of flexible tile adhesive, easy flow and damage to the flatness of the finish, etc., to improve the waterproof performance. , Good waterproof performance, the effect of preventing moisture intrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for preparing a three-in-one mortar for waterproofing, bonding and caulking, comprising the following steps:

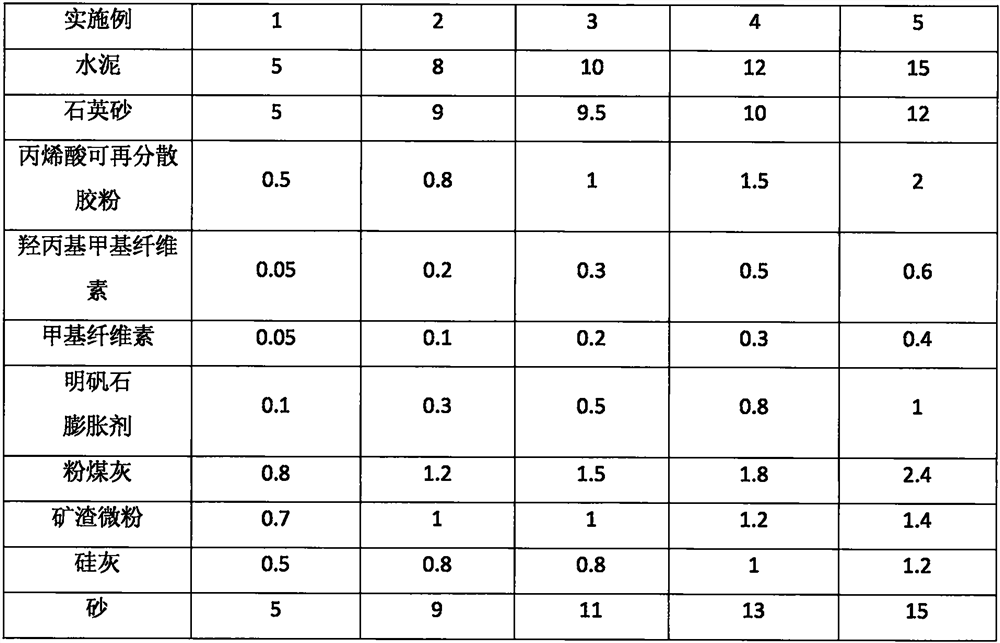

[0040](1) Weigh cement, quartz sand, acrylic acid redispersible rubber powder, acrylic acid redispersible rubber powder, methyl cellulose, alunite expansion agent, fly ash, slag micropowder, slag micropowder according to the raw material content in Table 1 , Sand with a particle size of 1-2mm;

[0041] (2) Put the weighed raw materials into the mixer, and stir and mix for 40 minutes to obtain a uniform three-in-one mortar of waterproofing, bonding and caulking.

Embodiment 2~5

[0043] The preparation method of a three-in-one mortar for waterproofing, bonding and caulking is the same as that of Example 1, and the addition amount of each raw material is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com