Vehicle paint surface defect detection device based on intelligent sensing and machine vision

A technology of machine vision and intelligent sensing, which is applied in the direction of measuring devices, optical testing defects/defects, instruments, etc., can solve problems affecting work efficiency, low work efficiency, and increasing the work intensity of staff, so as to improve work efficiency and reduce The effect of work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

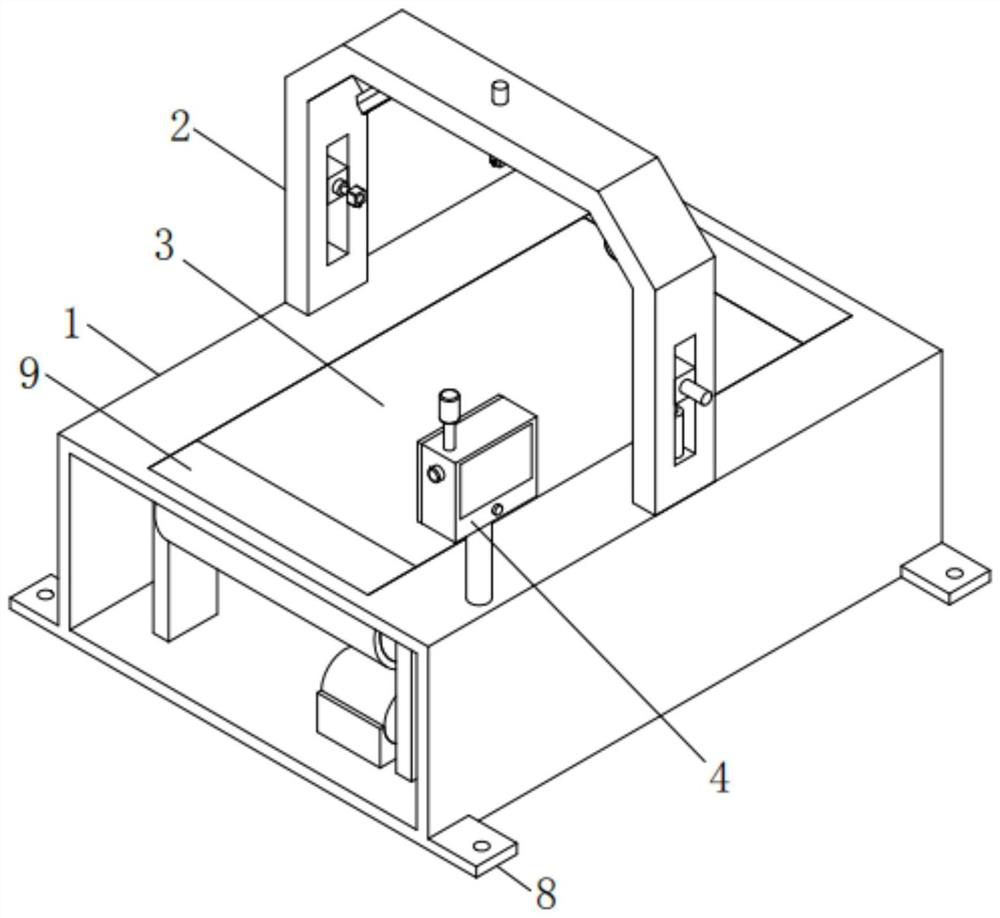

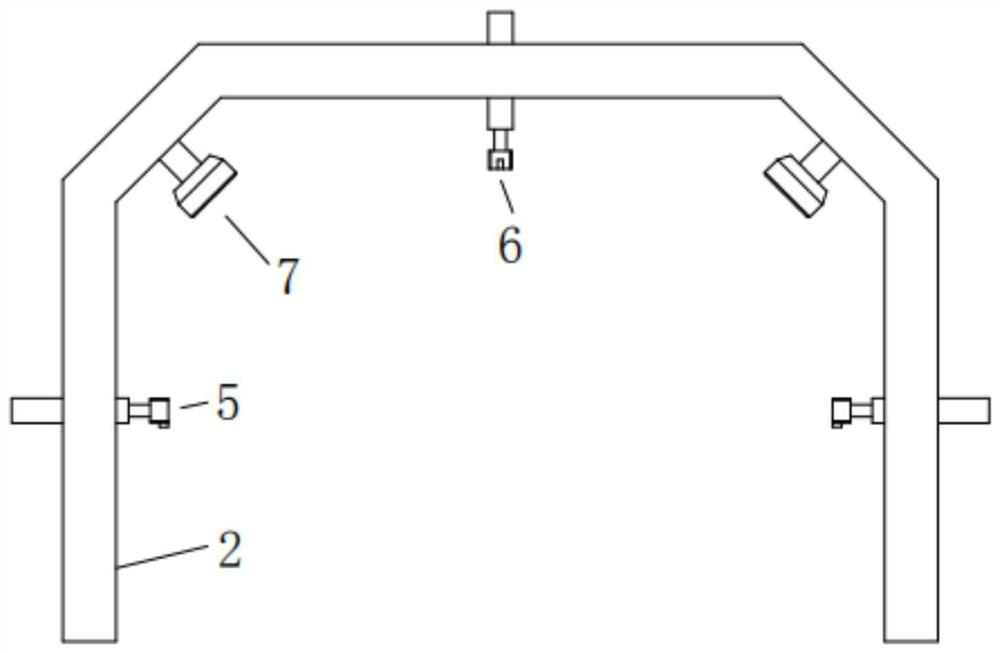

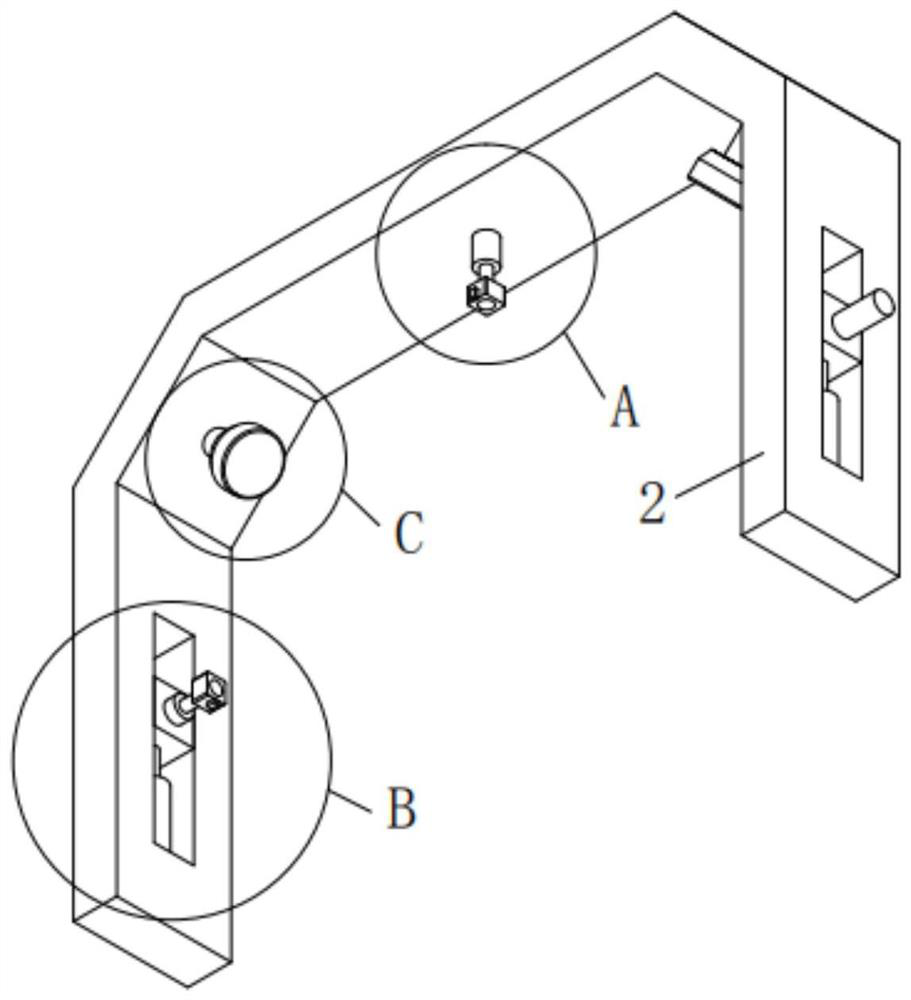

[0045] Such as Figure 1-Figure 2 As shown, a vehicle paint surface defect detection device based on intelligent sensing and machine vision includes a square hollow base 1, a gantry-shaped fixing frame 2, a transmission mechanism 3, two sets of side detection mechanisms 5, a top detection mechanism 6, two A set of lighting mechanism 7 and control mechanism 4, the square hollow base 1 is arranged horizontally, and a square through groove 10 is reserved in the center on the top wall of the square hollow base 1, and the gantry-shaped fixing frame 2 is vertically and fixedly Installed on the top of the square hollow base 1, and the gantry-shaped fixing frame 2 is set across the square slot 10, the transmission mechanism 3 is fixedly installed inside the square hollow base 1, and the transmission The upper part of the mechanism 3 runs through the square channel 10 and is arranged flush with the upper surface of the top wall of the square hollow base 1, and two sets of side detectio...

Embodiment 2

[0054] The difference from Example 1 is that a protective layer is also provided on the surface of the square hollow base 1, and the protective layer is prepared by the following method:

[0055] Take the following raw materials and weigh them by weight: 20-30 parts of epoxy resin, 10-12 parts of talc powder, 11-13 parts of aluminum oxide powder, 11-13 parts of chromium trioxide powder, 11-13 parts of phenolic resin, 8-10 parts of cobalt naphthenate, 3-5 parts of DMP-30 accelerator and 35-55 parts of water;

[0056] S1, adding epoxy resin, talcum powder, aluminum oxide powder, chromium oxide powder and phenolic resin into a ball mill for grinding until the particle diameter is not greater than 100nm, so as to prepare a mixed powder material;

[0057] S2. Add the mixed powder material prepared in step S1, cobalt naphthenate, DMP-30 accelerator and water into the reaction kettle and stir for 25-35min, the stirring speed is 800-1000r / min, and the temperature is 80-100°C , when t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com