Method for determining optimal processing direction of single crystal material

A processing direction, single crystal material technology, applied in the direction of analyzing materials, material inspection products, testing semiconductor materials, etc., can solve the problems of material surface quality, processing efficiency, processing force and tool wear, no problem, no processing direction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

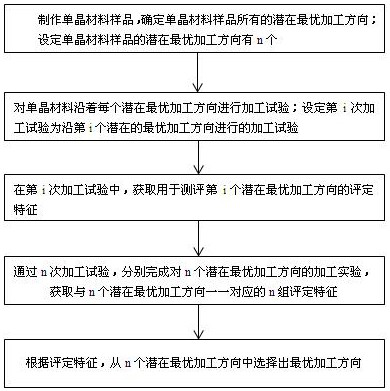

[0080] Such as figure 1 As shown, the present invention includes a method for determining the optimal processing direction of a single crystal material, comprising the following steps:

[0081] Step 1: Make a single crystal material sample, determine all potential optimal processing directions of the single crystal material sample; set n potential optimal processing directions for the single crystal material sample;

[0082] Step 2: Process the single crystal material sample along each potential optimal processing direction; set the i-th processing as processing along the i-th potential optimal processing direction;

[0083] Step 3: In the i-th processing, obtain the evaluation features used to evaluate the i-th potential optimal processing direction;

[0084] The evaluation features include processing force during processing, surface topography and subsurface damage layer depth after processing; the processing force includes tangential force and normal force;

[0085] 3.1: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com