A Numerical Simulation Solution and Drawing Method of the Wrinkling Instability Limit Diagram of Plate and Shell

A numerical simulation and limit diagram technology, applied in CAD numerical modeling, electrical digital data processing, special data processing applications, etc., can solve the problems of unpredictable wrinkling and instability morphology, and many factors that cause and affect, and achieve results. High reliability, accurate calculation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

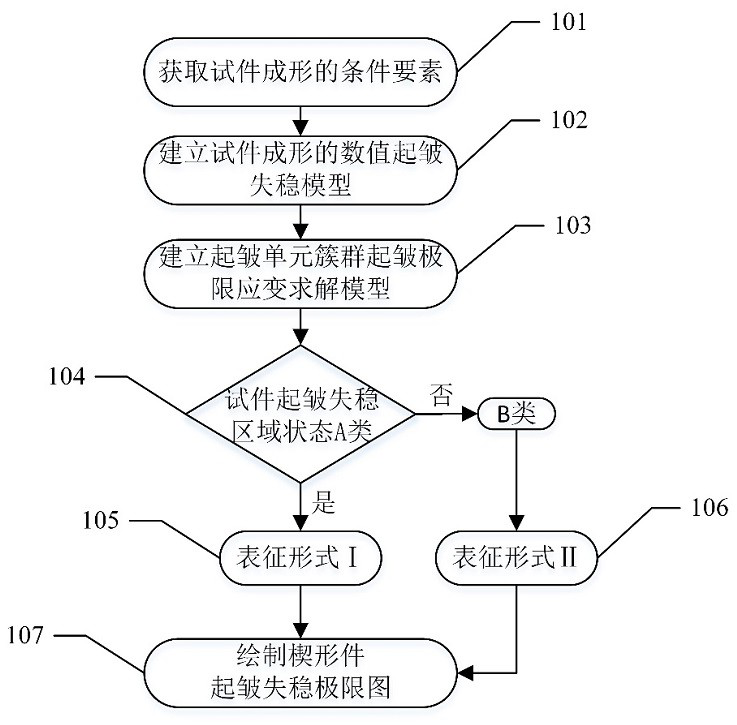

[0036] like figure 1 As shown in the figure, the numerical simulation solution and drawing method for establishing the wrinkling and instability limit diagram of metal plate shell material includes the following steps;

[0037] Step 101: Obtain the conditional elements for the forming of the sheet metal shell specimen;

[0038] Step 102: establish a numerical wrinkling and instability model for the forming of the metal plate and shell test piece according to the forming condition elements of the metal plate and shell test piece;

[0039] Step 103 : establish a wrinkling limit strain solution model for the wrinkling element cluster of the sheet metal shell specimen according to the numerical wrinkling instability model;

[0040] Step 104: Determine the representation form of the wrinkling and instability limit diagram of the plate and shell according to the state type of the wrinkling and instability region of the metal plate and shell specimens;

[0041] Step 105: If the sta...

Embodiment 2

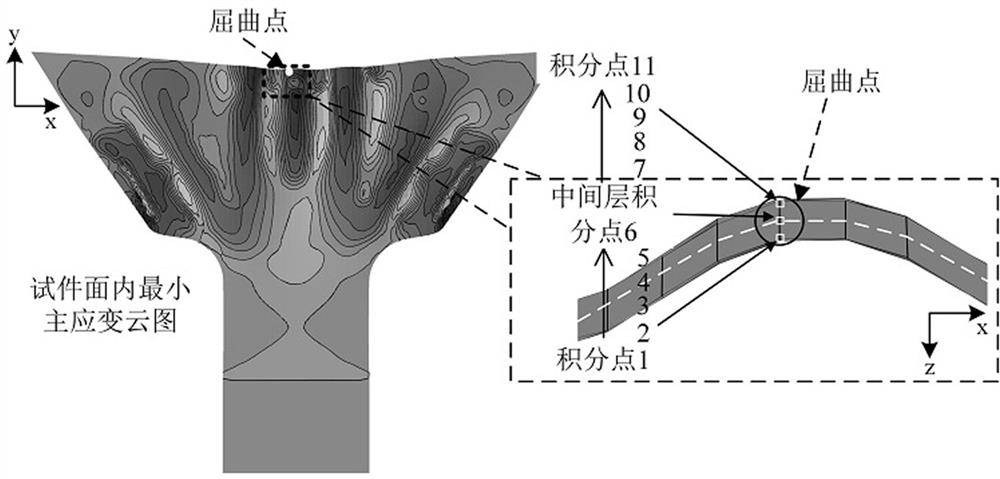

[0061] Now take the wedge-shaped member with plate thickness t=0.9mm and geometric dimension h=48mm as an example. The specific process of establishing the wrinkling limit strain solution model of wrinkling element clusters based on the numerical wrinkling instability model is described in detail.

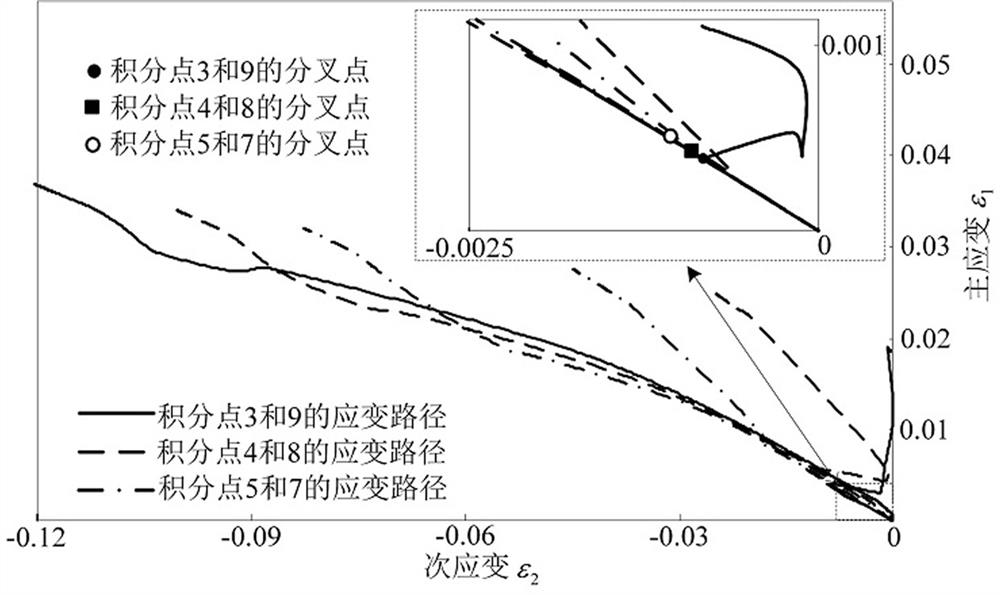

[0062] When the metal sheet is plastically deformed, wrinkled and unstable, the inner and outer forces in the thickness direction of the wrinkle are different. The inner material is under compressive stress due to being squeezed, while the outer side is under tensile stress. Therefore, when the wrinkling position enters the critical wrinkling state from the initial steady state deformation, the strain paths corresponding to the inside and outside of the wrinkle will be bifurcated, and the moment corresponding to the bifurcation point is defined as the critical moment when the sheet begins to wrinkle.

[0063] In the tensile numerical simulation results of wedges, the extreme point...

Embodiment 3

[0068] In this example, the YBT test is taken as the research object, and the process of establishing the wrinkling and instability limit diagram of the metal plate and shell in the type I characteristic form is described in detail by applying the numerical simulation solution and drawing method of the wrinkling and instability limit diagram of the plate and shell of the present invention.

[0069] The numerical simulation model of YBT test stretch forming based on the YBT test stretch forming condition elements in this example is shown in Figure 4 , the plate is a deformable body, and the material properties are based on the GB / T 228.1-2010 test standard for the size design and blanking of the uniaxial tensile test piece for the 304 stainless steel plate, and the WDW-100kN high and low temperature microcomputer controls the electronic universal material experiment. The test was divided into three groups to test the true stress-strain curves of the specimens in the directions ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com