Negative electrode sheet and secondary battery

A technology of secondary battery and negative electrode sheet, applied in the direction of secondary battery, negative electrode, battery electrode, etc., can solve the problems of low initial charge and discharge efficiency, low initial charge and discharge efficiency, and large volume expansion of power batteries. Reduced irreversibility, first charge-discharge efficiency, improved cycle performance, and high specific energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

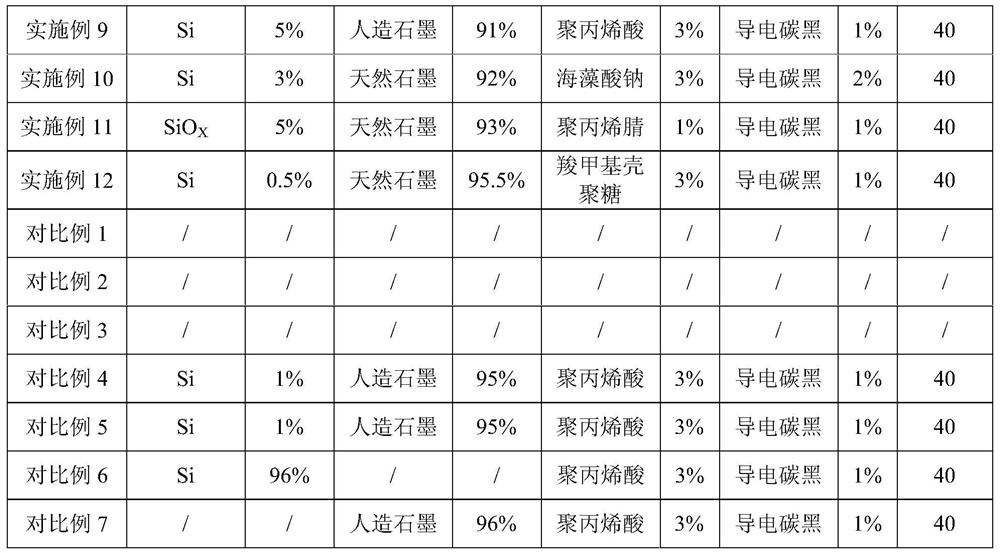

Examples

preparation example Construction

[0037] In the negative electrode sheet described in the first aspect of the present application, the preparation method of the negative electrode sheet may include the steps of:

[0038] (1) Preparation of the first negative electrode slurry: disperse the silicon-based material, carbon material, binder and conductive agent in deionized water in a certain proportion, and stir for 0.5h to 8h;

[0039] (2) Preparation of the second negative electrode slurry: disperse the silicon-based material, carbon material, binder and conductive agent in deionized water in a certain proportion, and stir for 0.5h to 8h;

[0040] (3) Preparation of negative electrode sheet: the second negative electrode slurry is coated on the negative electrode current collector to form the second coating, and then the first negative electrode slurry is coated on the second coating to form the first coating, and then the Cold pressing and slitting to obtain the negative electrode sheet.

[0041] Next, a secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com