Al-based composite material as well as preparation method and application thereof

A composite material and equipment technology, applied in the field of Al-Bi-TiB2 composite material and preparation, can solve the problems affecting the mechanical properties of Al-Bi alloy, delamination phenomenon, Al-Bi alloy cannot realize the uniform distribution of Bi-rich phase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

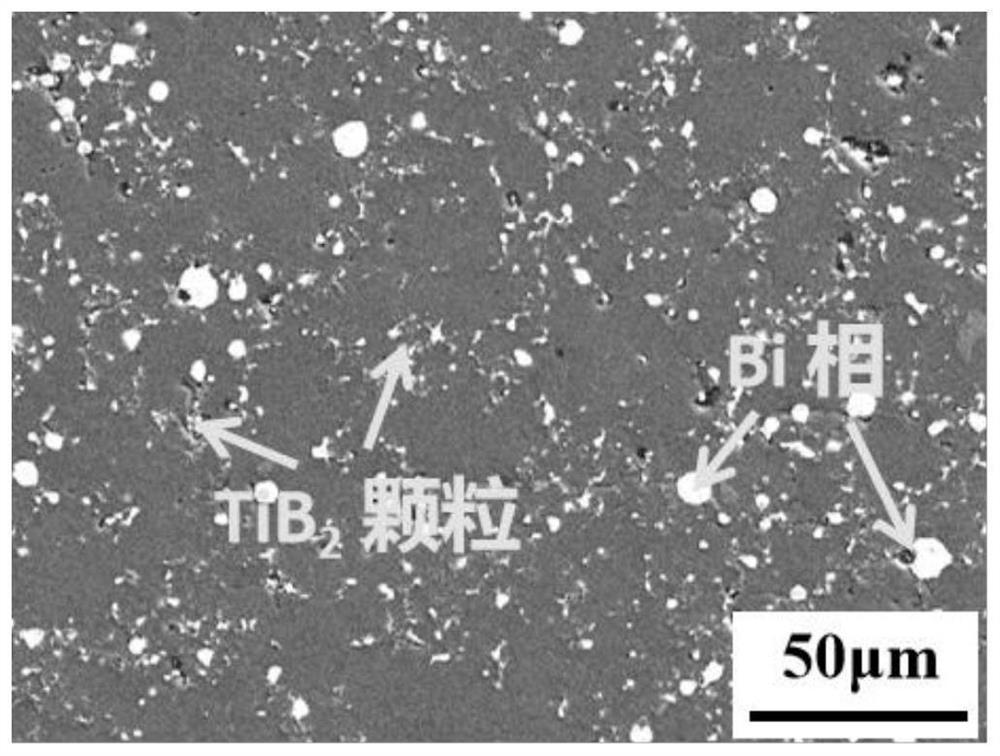

[0030] The invention provides an Al-Bi-TiB 2 The preparation method of composite material, comprises the following steps:

[0031] TiB 2p / Al composite material and Bi simple substance are heated and melted to obtain Al-Bi-TiB 2 melt; the TiB 2p TiB in / Al composites 2 The mass percentage of particles is ≤6%, and the Al-Bi-TiB 2 The mass percentage of Bi phase in the melt is ≤20%;

[0032] The Al-Bi-TiB 2The melt is cast after ultrasonic treatment to obtain the Al-Bi-TiB 2 composite material.

[0033] In the present invention, the TiB 2p TiB in / Al composites 2 The mass percentage of the particles is ≤6%, preferably 3-6%, more preferably 4-5%.

[0034] In the present invention, the TiB 2p The preparation method of / Al composite material comprises the following steps:

[0035] Mix and melt aluminum melt, borofluoride and titanate fluoride to obtain Al-TiB 2 Melt; the molar ratio of borofluorate and titanium fluoride is TiB 2 The atomic ratio of Ti element and B el...

Embodiment 1

[0079] Heat and melt the aluminum element to obtain an aluminum melt with a temperature of 800°C, according to TiB 2 The atomic ratio of Ti element and B element in, and TiB 2p TiB in / Al composites 2 The mass percentage of particles is 3-5%, and KBF is added to the aluminum melt 4 and K 2 TiF 6 Finally, keep warm at 800°C for 30 minutes, pour out the upper layer of impurities, and pour the remaining melt into a metal mold to cool and form after stirring to obtain TiB 2 p / Al composite material;

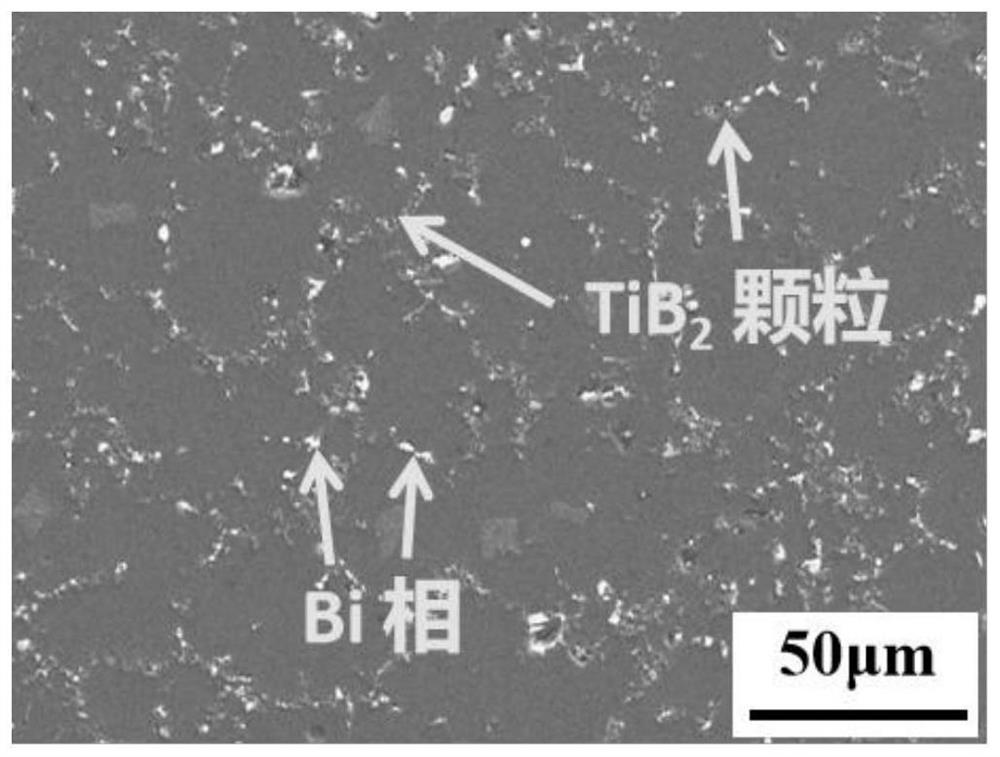

[0080] TiB 2p / Al composite material is placed in a resistance furnace, and when the temperature is raised to 920-950°C at 15°C / min, the TiB 2p Al-Bi-TiB is obtained by adding Bi powder into the Al composite 2 For the initial melt, continue to increase the temperature at 20°C / min to 1020-1050°C, then mechanically stir and heat-preserve for 10 minutes to obtain Al-Bi-TiB 2 Melt, where Al-Bi-TiB 2 The mass percentage of Bi phase in the melt is 5%;

[0081] Al-Bi-TiB 2 Ultraso...

Embodiment 2

[0085] Heat and melt the aluminum element to obtain an aluminum melt with a temperature of 800°C, according to TiB 2 The atomic ratio of Ti element and B element in, and TiB 2p TiB in / Al composites 2 The mass percentage of particles is 3-5%, and KBF is added to the aluminum melt 4 and K 2 TiF 6 Finally, keep warm at 800°C for 30 minutes, pour out the upper layer of impurities, and pour the remaining melt into a metal mold to cool and form after stirring to obtain TiB 2 p / Al composite material;

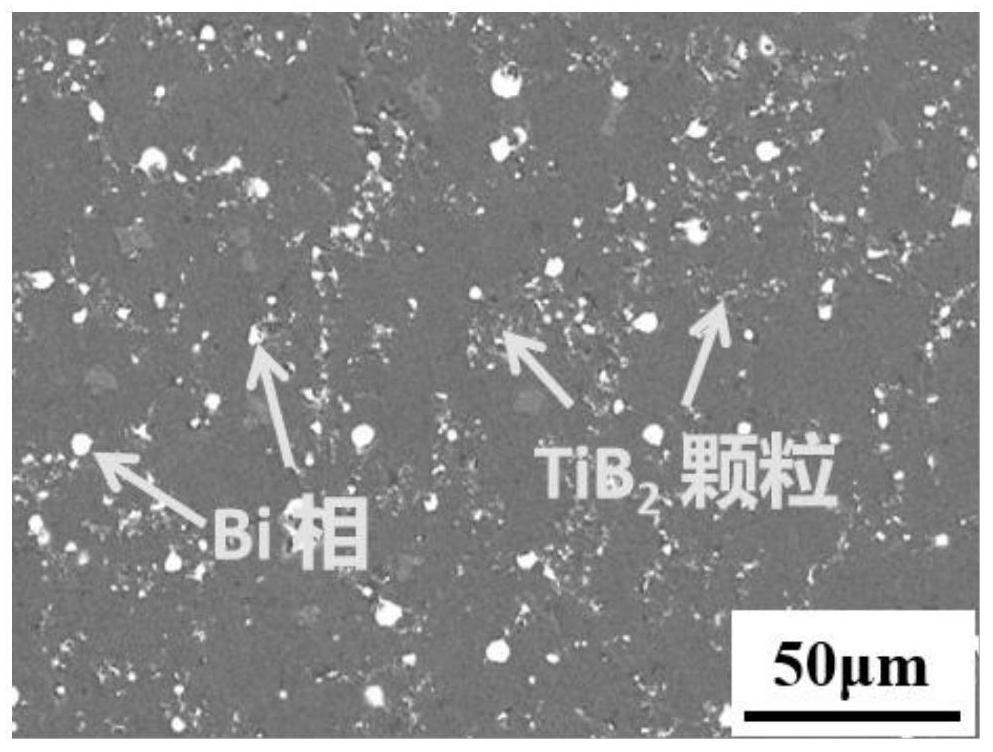

[0086] TiB 2p / Al composite material is placed in a resistance furnace, and when the temperature is raised to 920-950°C at 15°C / min, the TiB 2p Al-Bi-TiB is obtained by adding Bi powder into the Al composite 2 For the initial melt, continue to increase the temperature at 20°C / min to 1020-1050°C, then mechanically stir and heat-preserve for 10 minutes to obtain Al-Bi-TiB 2 Melt, where Al-Bi-TiB 2 The mass percentage of Bi phase in the melt is 10%;

[0087] Al-Bi-TiB 2 Ultras...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com