A gelatable system containing straight-chain ether compounds and its preparation method and application

An ether compound, gelation technology, applied in electrochemical generators, electrical components, secondary batteries, etc., can solve the problems of time-consuming and laborious preparation, cumbersome and lengthy experimental methods, and different

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

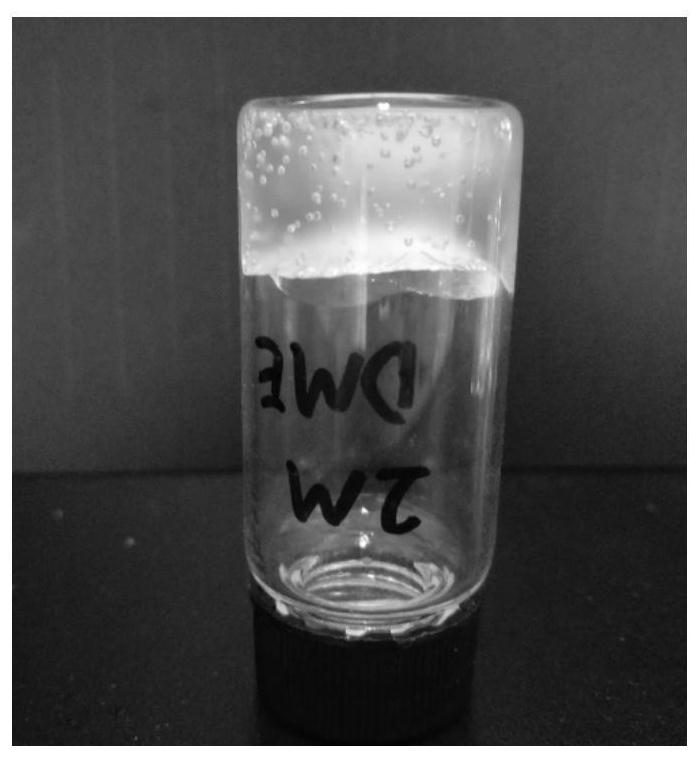

[0113] (1) Preparation of gelable system and gel (gel electrolyte that can be used as battery)

[0114] Weigh 0.7g of lithium perfluorobutane sulfonate solid in a reagent bottle, add 3.0mL of ethylene glycol methyl ethyl ether and 2.0 mL of ethylene glycol diethyl ether (water has been removed through molecular sieves before use), under magnetic stirring , to be prepared into lithium perfluorobutanesulfonate / ethylene glycol methyl ethyl ether+ethylene glycol diethyl ether solution with a lithium salt content of 12wt%, and continue to stir for a period of time to obtain a gelatable system; glue.

[0115] In the gel system, the mass percentage of the lithium salt is 12 wt %; the mass percentage of the linear ether compound is 88 wt %.

[0116] After testing, the formation time of the gel is 24 hours; the formation temperature of the gel is room temperature, the transition temperature of the gel is 67°C, and the conductivity of the gel is 4.97×10 -4 S / cm.

[0117] When the pre...

Embodiment 2

[0119] (1) Preparation of gelable system and solid electrolyte

[0120] Weigh 0.45g of lithium hexafluorophosphate (LiPF 6 ) and 0.45g of lithium perchlorate (LiClO 4 ) solid in a reagent bottle, add 3.6mL of ethylene glycol dimethyl ether (water has been removed through molecular sieves before use), and under magnetic stirring, it is prepared into LiPF with a lithium salt content of 20wt%. 6 +LiClO 4 / ethylene glycol methyl ethyl ether, and continue to stir to obtain a gelatinable system; stand for a period of time to obtain a solid electrolyte.

[0121] In the solid electrolyte system, the mass percentage of lithium salt is 20 wt%; the mass percentage of linear ether compounds is 80 wt%.

[0122] After testing, the formation time of the solid electrolyte is 12 hours; the formation temperature of the solid electrolyte is room temperature, the transition temperature of the solid electrolyte is 84°C, and the conductivity of the solid electrolyte is 3.31×10 -6 S / cm.

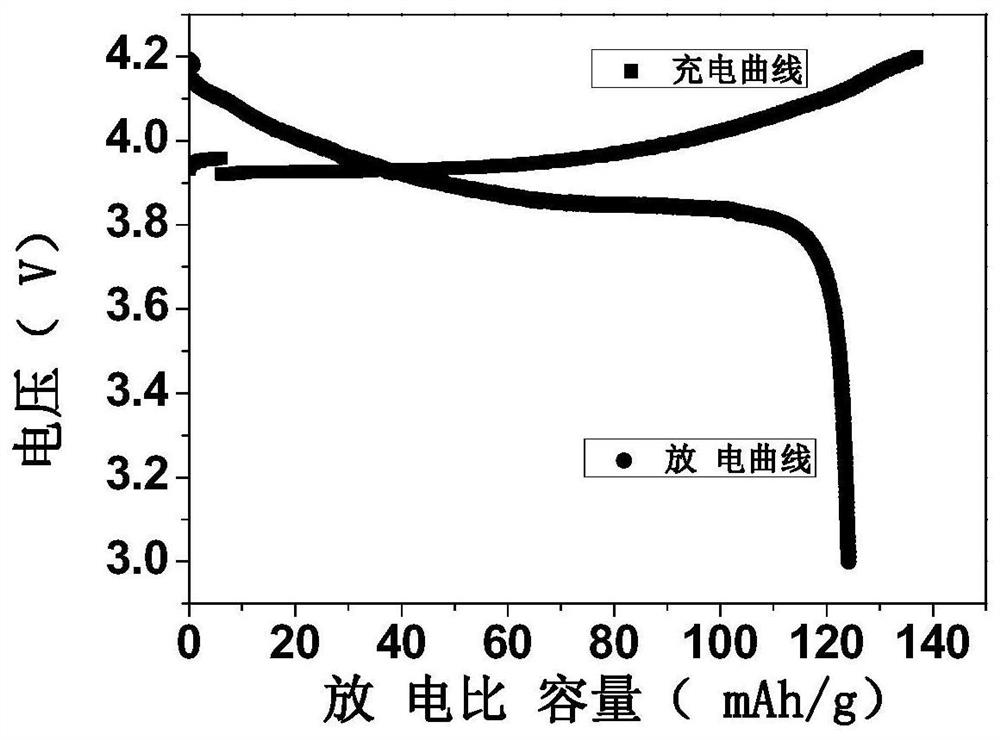

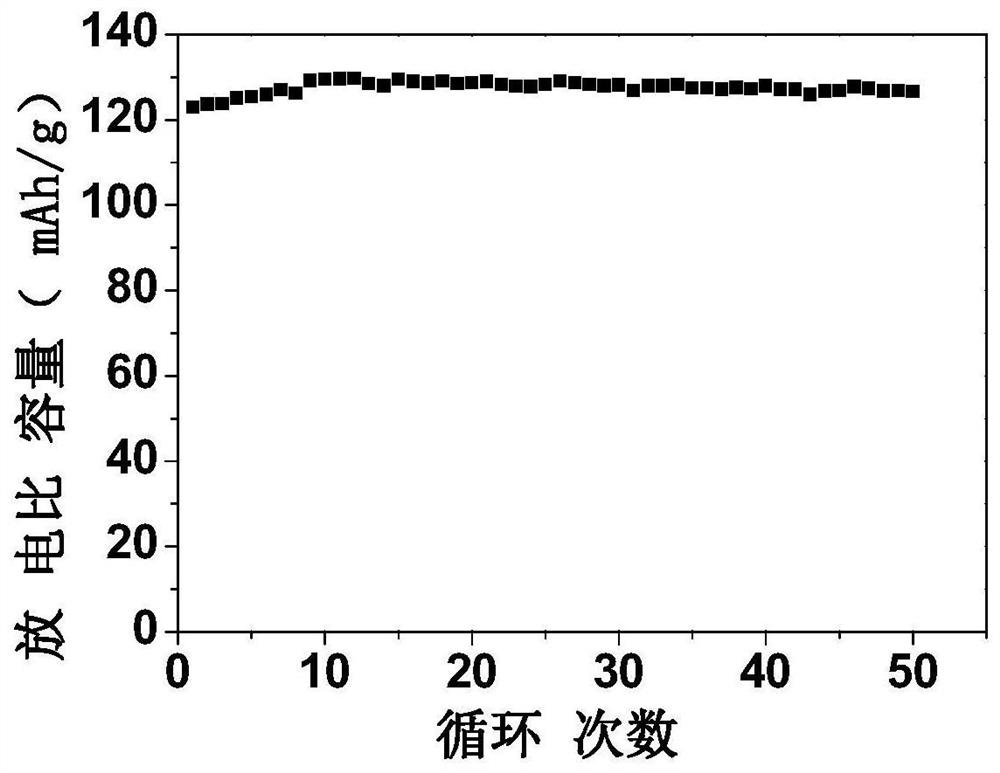

[0123...

Embodiment 3

[0125] (1) Preparation of gelable system and gel (gel electrolyte that can be used as battery)

[0126] Weigh 0.4g of lithium perchlorate and 0.2g of lithium hexafluoroarsenate solid in the reagent bottle, add 1.0mL of lithium-ion battery conventional electrolyte (containing 1mol / L LiPF 6 A mixed solution of dimethyl carbonate (DMC) and ethylene carbonate (EC) with a volume ratio of 1:1), the lithium salt was completely dissolved under magnetic stirring, and then 1.5 mL of 1,4-butanediol dimethyl ether was added In the above mixed solution, after being fully mixed, a gelatable system is obtained; after standing for a period of time, a gel is formed.

[0127] In the gel system, the mass percentage of lithium salt is 19 wt%, the mass percentage of linear ether compounds is 48 wt%, and the mass percentage of other solvents and / or electrolytes is 33 wt%.

[0128] After testing, the performance parameters of the gel are listed in Table 1.

[0129] When the prepared gel is heated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com