An organic system supercapacitor or capacitor battery

A technology for supercapacitors and capacitor batteries, applied in the direction of hybrid capacitor electrolytes, etc., can solve the problems of leakage of liquid electrolyte, increase in cost, easy damage of gel state, etc., achieve high transition temperature and reversibility, strong impact resistance, The effect of high charge and discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0107] [Preparation method of gel electrolyte]

[0108] The present invention also provides a kind of preparation method of above-mentioned gel electrolyte, it comprises the following steps:

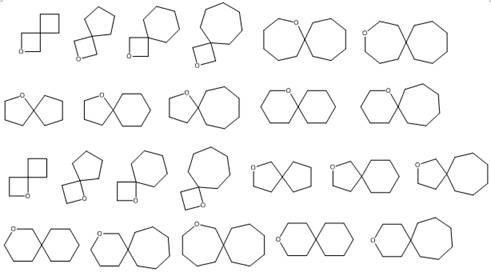

[0109] The ether compound, the lithium salt, and optionally the electrolyte solution or its solvent for an organic system supercapacitor or capacity battery and optionally inorganic nanoparticles and optional additives are mixed to obtain the ether compound of the lithium salt under stirring The solution, that is, the gelatable system, is continuously stirred to obtain the gel electrolyte through gelation.

[0110] Preferably, the preparation method of the gel electrolyte specifically includes the following steps:

[0111] The ether compound is added in the lithium salt, and the ether compound solution of the lithium salt is obtained under stirring, and optionally the electrolyte solution or its solvent and / or inorganic nanoparticles and / or additives for supercapacitors or capacitor bat...

Embodiment 1

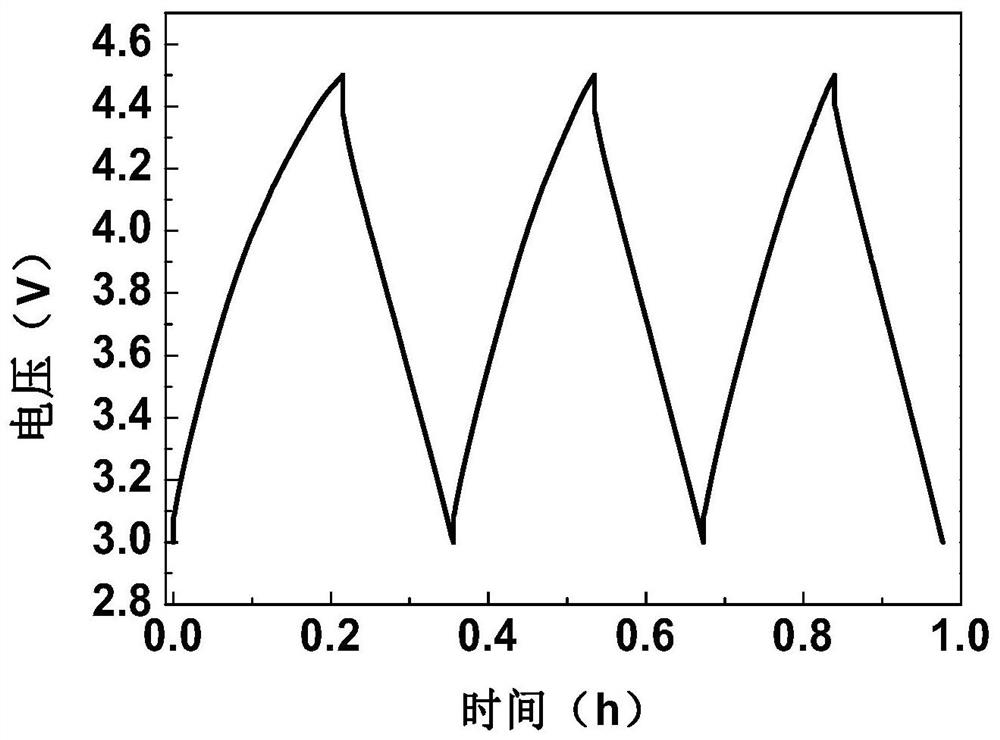

[0148] (1) Preparation of gel electrolyte used as supercapacitor

[0149] Weigh 0.8g of lithium hexafluorophosphate solid into a reagent bottle, add 9.2mL of tetrahydropyran, and mix thoroughly under magnetic stirring to obtain a gelatinable system; let it stand for a while to form a gel electrolyte.

[0150] In the gel system, the mass percent of lithium salt is 8wt%, the mass percent of ether compound is 92wt%, and the mass percent of electrolyte solution or its solvent for lithium ion battery is 48wt%.

[0151] After testing, the performance parameters of the gel are listed in Table 1.

[0152] When the prepared gel was heated above the transition temperature of the gel, the gel began to become viscous, and the gel would be observed to flow downward when the reagent bottle was inverted, indicating that the temperature had reached the transition temperature of the gel, and when the temperature When the temperature dropped below the transition temperature of the gel, the gel...

Embodiment 2

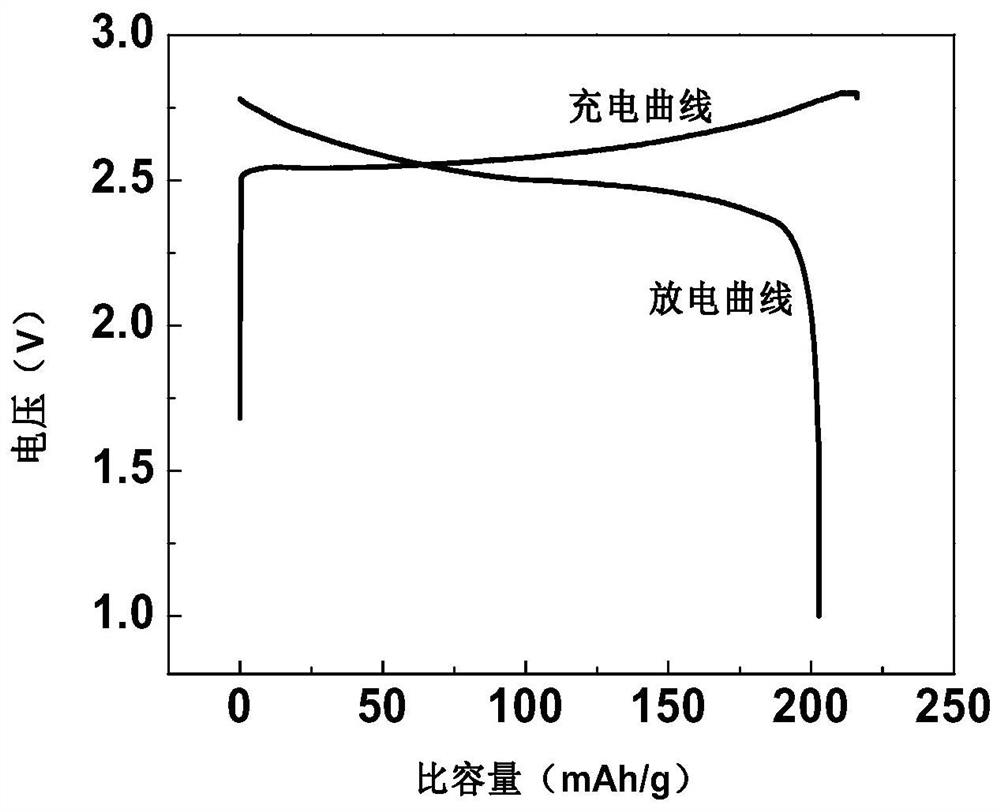

[0158] (1) Preparation of gel electrolyte used as capacitor battery

[0159] Weigh 1.0g of lithium perchlorate and 0.5g of lithium trifluoromethanesulfonate solid in a reagent bottle, add 8.5mL of ethylene glycol methyl ethyl ether to the above mixture, and mix thoroughly to obtain a gelatable System; stand for a period of time to form a gel electrolyte.

[0160] In the gel system, the mass percent content of lithium salt is 15 wt %; the mass percentage content of ether compounds is 85 wt %.

[0161] After testing, the performance parameters of the gel are listed in Table 1.

[0162] When the prepared gel was heated above the transition temperature of the gel, the gel began to become viscous, and the gel would be observed to flow downward when the reagent bottle was inverted, indicating that the temperature had reached the transition temperature of the gel, and when the temperature When the temperature dropped below the transition temperature of the gel, the gel was re-forme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com