Precise punching equipment for router plastic shell

A technology of plastic shell and punching equipment, applied in metal processing equipment, grinding/polishing equipment, grinder, etc., can solve the problem of low precision of manual drilling, and achieve the convenience of manual observation, ensure accuracy, and improve work safety. Effects of Sex and Convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

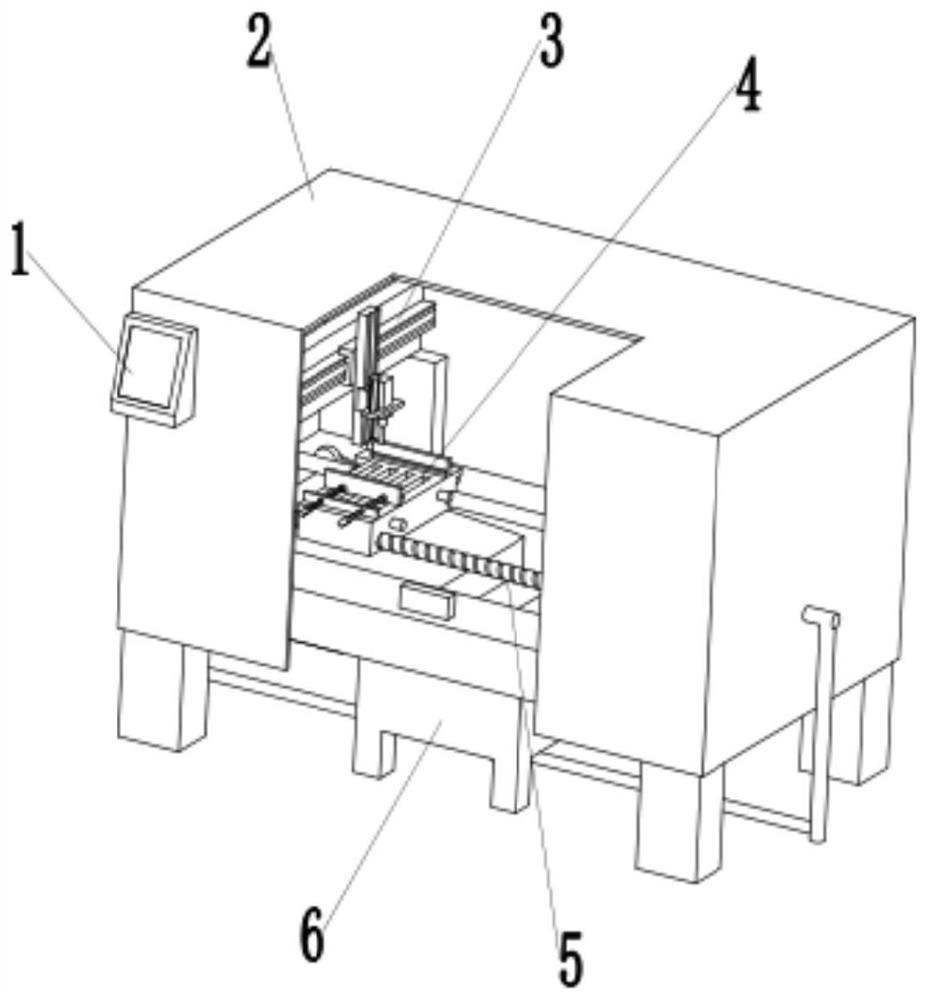

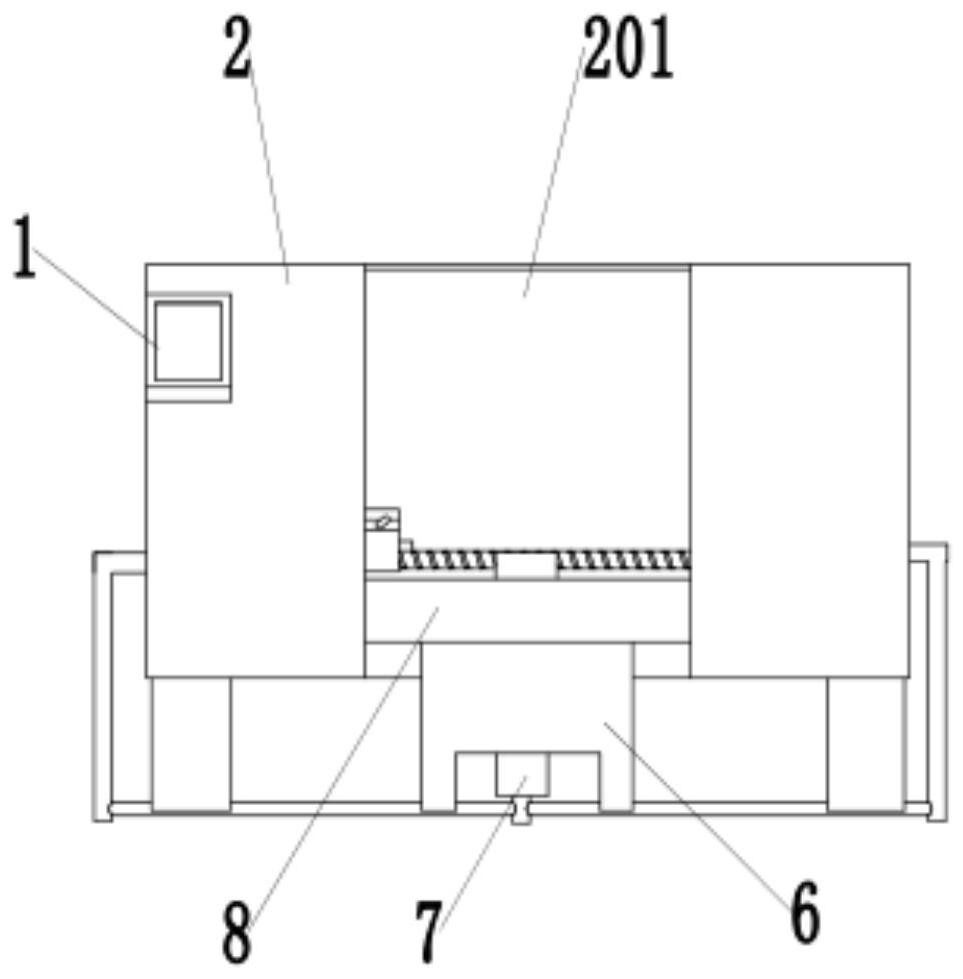

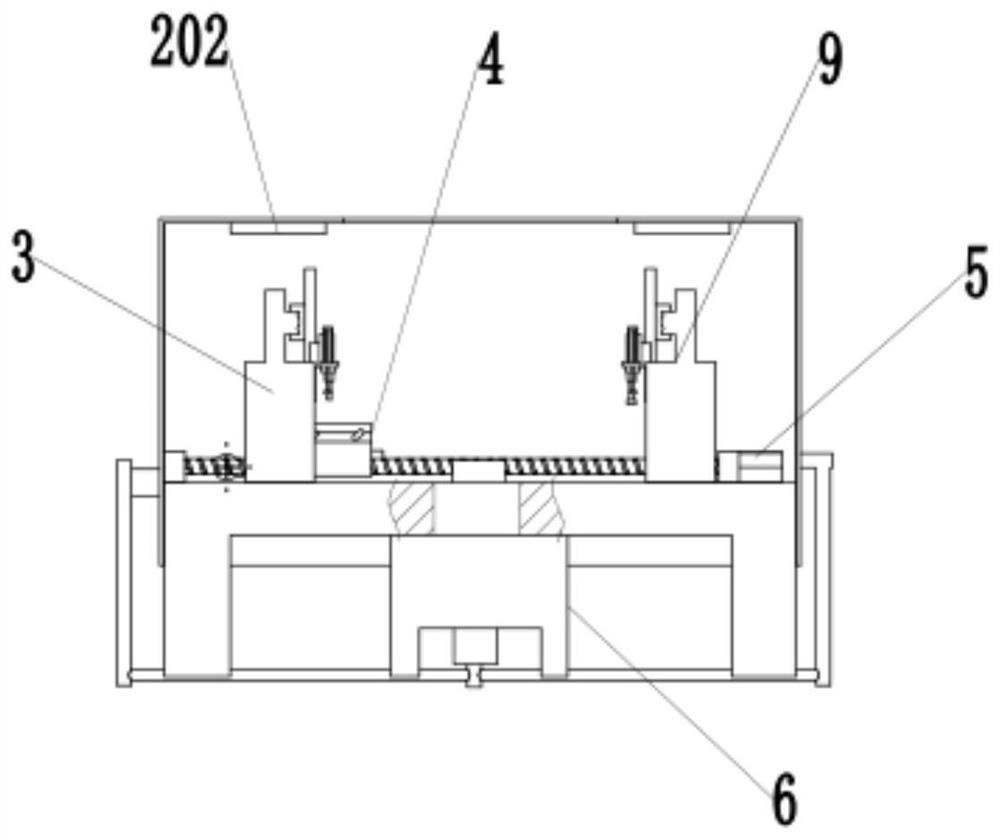

[0035] Such as Figure 1-4 As shown, a router plastic casing precision drilling equipment, including a controller 1, a machine cover 2, a drilling mechanism 3, a driving mechanism 5, a workbench 8 and a grinding mechanism 9, the upper end of the workbench 8 is provided with a drive mechanism 5 , the driving mechanism 5 is provided with a punching table 4 that slides left and right along a straight line, the punching table 4 is provided with a blanking hole 411, and the debris after punching falls from the blanking hole 411, and the two ends of the driving mechanism 5 A drilling mechanism 3 and a grinding mechanism 9 connected to the workbench 8 are provided. The drilling mechanism 3 and the grinding mechanism 9 are located above the punching table 4. The upper end of the workbench 8 is covered with a machine cover 2, and the middle part of the machine cover 2 is provided with a The hole 201 for placing the product is convenient, the drilling mechanism 3 and the grinding mechan...

Embodiment 2

[0045] In order to further ensure the operation safety of workers;

[0046] Such as Figure 5 As shown, the upper end of the workbench 8 is provided with an infrared sensor 803 electrically connected to the controller 1. The infrared sensor 803 is located at the hole 201. When the infrared sensor 803 detects a human body, the device will not start to ensure safety.

Embodiment 3

[0048] Such as image 3 , 5 As shown, in order to improve the thoroughness of waste cleaning, a fan 7 is provided below the waste box 6, and a flat air outlet 701 is provided on the inner side of the first fixed plate 502 and the second fixed plate 505, and the air outlet The mouth 701 is connected with the blower 7 through the air pipe, and the debris is blown into the collection hole 802 by the blower 7, which saves cleaning time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com