Intelligent chemical fiber yarn winding device

A chemical fiber and yarn technology, applied in the field of intelligent chemical fiber yarn winding device, can solve the problems of inconvenient movement, poor cushioning and positioning effect of the storage rack, inconvenient winding roller support function, etc., and achieve the convenience of movement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

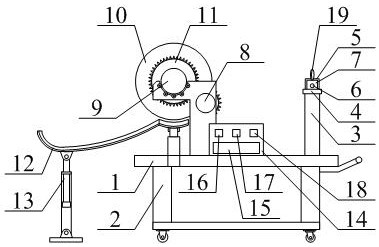

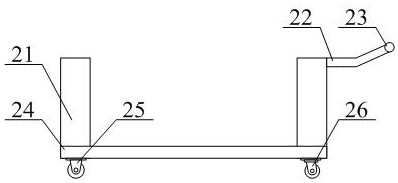

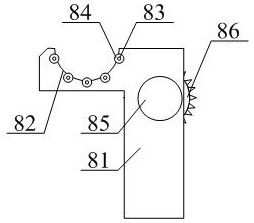

[0041] as attached figure 1 And attached Figure 4 shown

[0042] The invention provides an intelligent chemical fiber yarn winding device, which includes a workbench 1, a movable frame structure 2, a longitudinal support plate 3, a transverse slide rail 4, a rotating motor 5, a threaded rod 6, a slider 7, and a storage drive Frame structure 8, winding roller 9, protective disc 10, driven gear 11, adjustable support structure 12, buffer support structure 13, control frame 14, controller 15, first switch 16, second switch 17, third switch 18 and positioning ring 19, the movable frame structure 2 is installed on the lower part of the workbench 1; two longitudinal support plates 3 are provided, and the bolts of the longitudinal support plate 3 are installed on the upper right side of the workbench 1 The front and rear ends of the front and rear ends; the 4 bolts of the horizontal slide rail are installed on the upper side of the longitudinal support plate 3; the 5 bolts of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com