Shock absorber

A shock absorber and working cylinder technology, which is applied in the field of machinery, can solve problems such as insufficient adaptability of shock absorbers, and achieve the effects of stable use, improved stability, and guaranteed stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

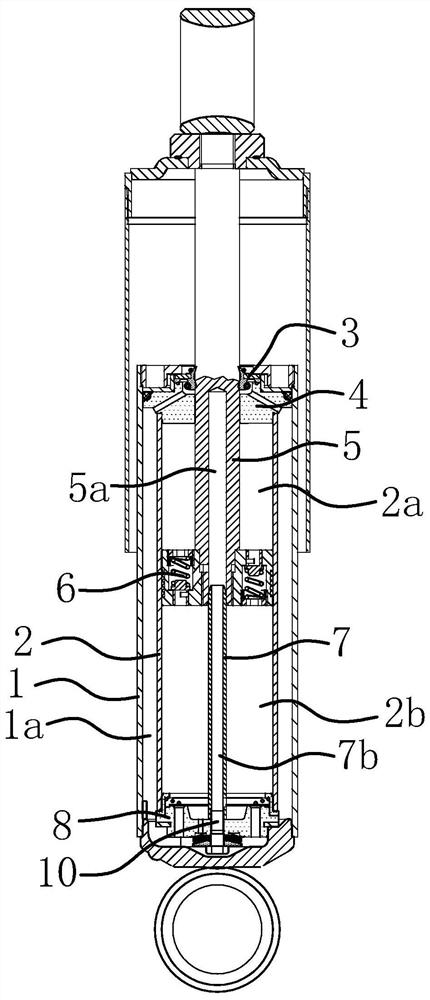

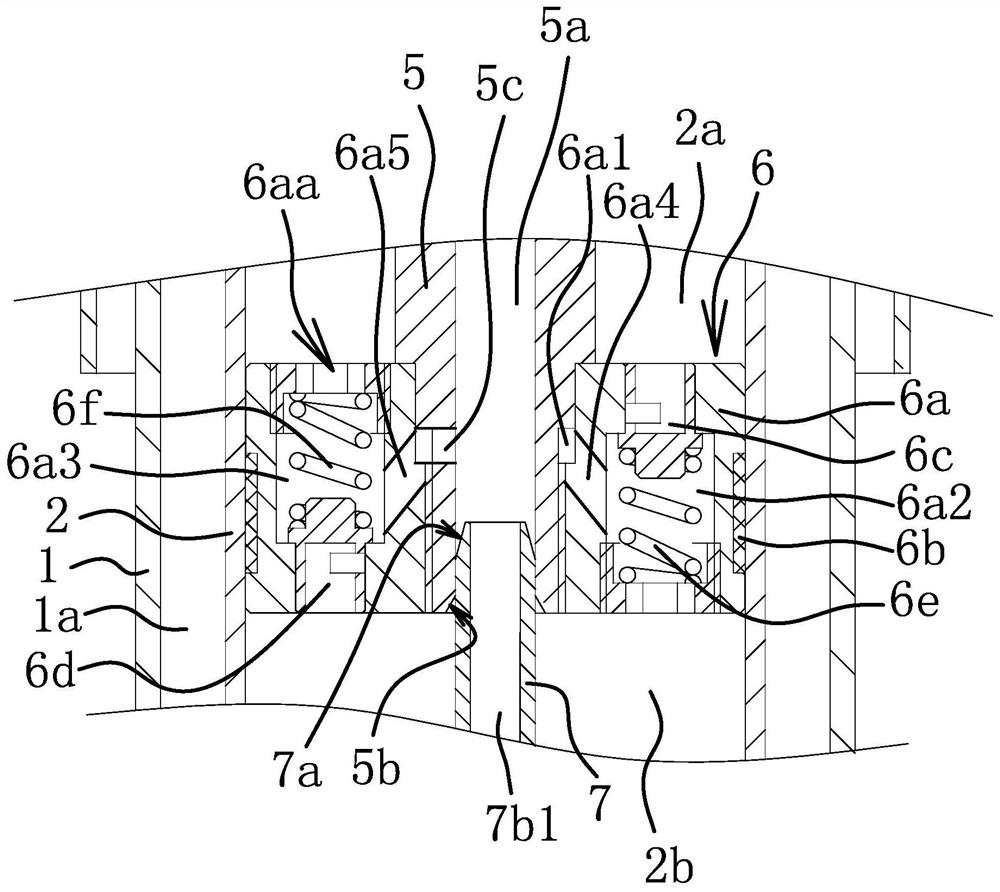

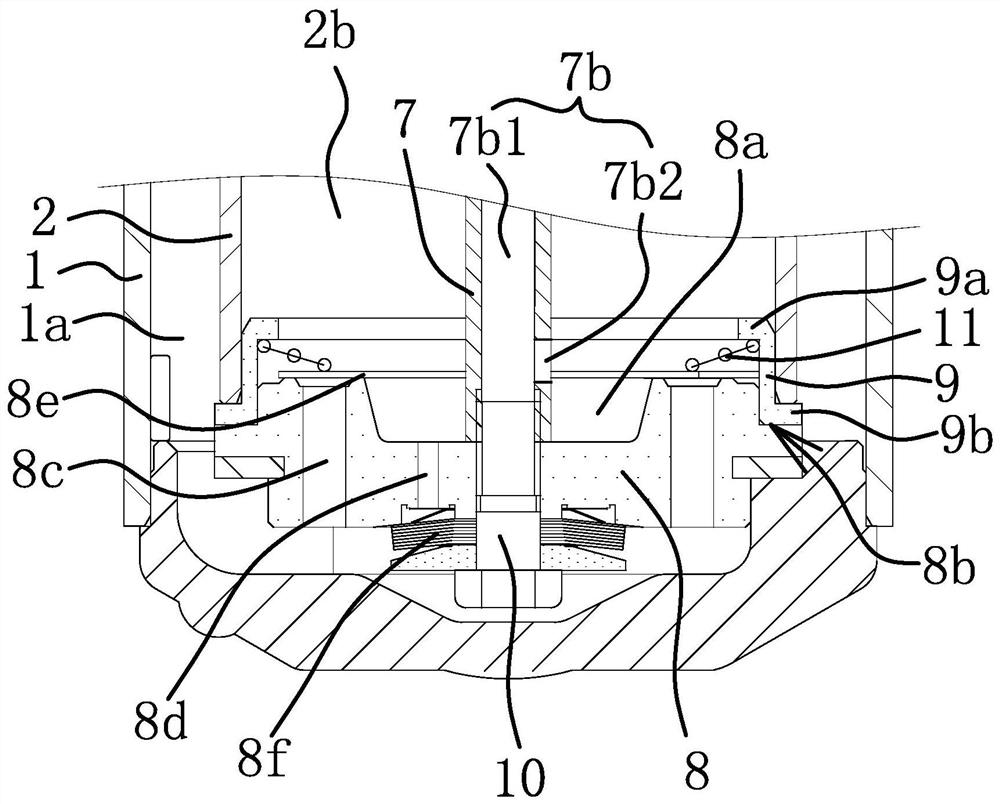

[0047] Such as Figure 1-Figure 3 As shown, a shock absorber includes an oil storage cylinder 1 and a working cylinder 2 arranged in the oil storage cylinder 1. There is an oil storage chamber 1a between the outer surface of the working cylinder 2 and the inner surface of the oil storage cylinder 1. The oil storage cylinder 1 The top end is fixed with an oil seal 3 and a guide 4, the top of the working cylinder 2 is connected to the guide 4, a bottom valve 8 is arranged between the bottom end of the working cylinder 2 and the bottom end of the oil storage cylinder 1, and the inner cavity of the working cylinder 2 A movable piston rod 5 is provided, and the top end of the piston rod 5 extends out of the top end of the oil storage cylinder 1 after passing through the guide 4 and the oil seal 3, and the bottom end of the piston rod 5 is fixed with a piston assembly 6, and the piston assembly 6 will work The inner chamber of the cylinder 2 is divided into a top chamber 2a and a bo...

Embodiment 2

[0057] The structure of the backflow channel 7b is different from that of Embodiment 1. The backflow channel 7b includes a long groove arranged on the outer surface of the valve stem 7. The top end of the long groove runs through the top surface of the valve stem 7, and the bottom end of the long groove extends to the bottom of the valve stem 7. bottom.

[0058] The flow passage 6aa is different from the first embodiment. The flow passage 6aa includes an axial hole that runs through the top end surface of the piston body 6a and the bottom end surface of the piston body 6a. The inner surface of the piston body 6a is provided with a radial hole, and the radial hole is connected to the shaft. It is connected to the hole, and the radial hole is connected with the throttle hole 5c. The diameter of the radial hole is larger than or equal to the throttle hole 5c. The diameter of the axial hole is larger than the diameter of the throttle hole 5c. The diameter of the axial hole is large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com