Chemical oil generation detection system and equipment thereof

A detection system and oil generation technology, applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problems of unreasonable follow-up processing of performance parameters, inaccurate collection of performance parameters, single monitoring method, etc., to improve automatic Detection capabilities, rich application scenarios, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

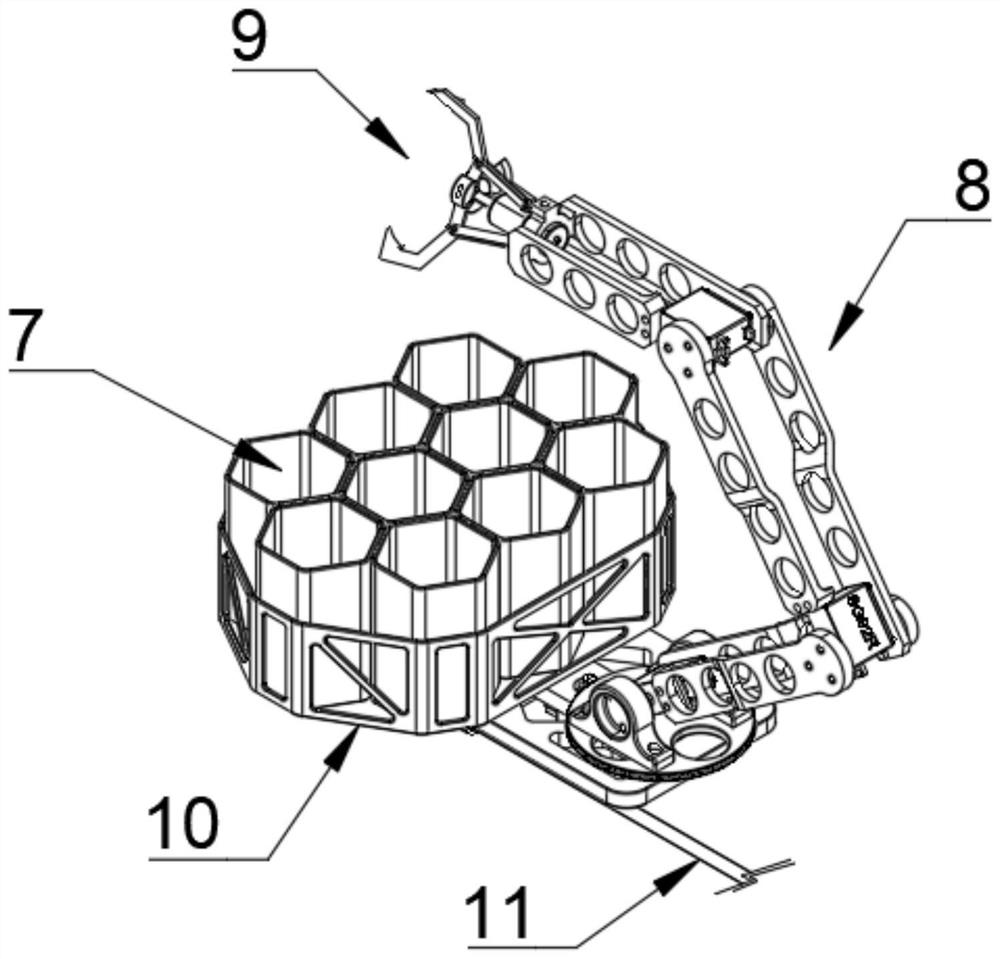

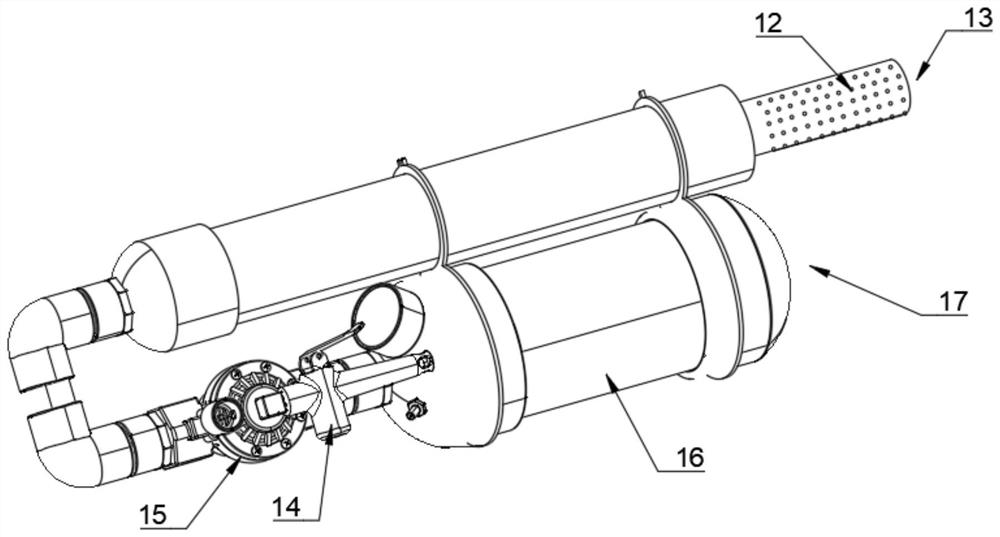

[0029] Embodiment 1: A chemical oil generation detection system and its equipment, including a housing chamber, a detection device, a sampling device, an analysis device, a reaction device 26 and a controller, the detection device is configured to detect the oil stored in the housing chamber The sample is detected; the sampling device is configured to be used in conjunction with the detection device, and to sample and detect the detected oil sample; the analysis device is configured to analyze the results of the detection device and the sampling device analysis; the reaction device 26 is configured to collect the detection oil sample and identify substances in the detection oil sample; the detection device, the sampling device, the analysis device and the reaction device 26 Control connection with the controller respectively.

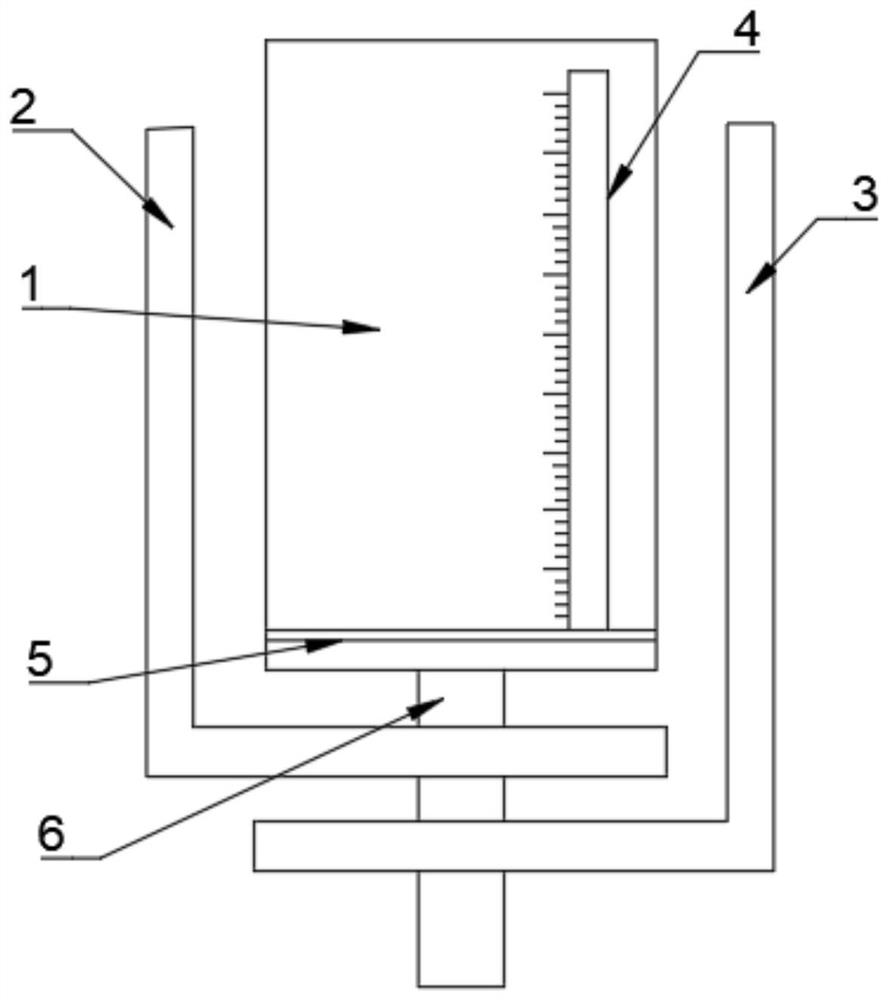

[0030]The detection device includes a detection probe, a detection container 1, a receiving mechanism, a first offset mechanism 2 and a second offset m...

Embodiment 2

[0031] Embodiment 2: This embodiment should be understood as at least including all the features of any one of the foregoing embodiments, and further improvements are made on the basis thereof. Specifically, a chemical oil production detection system and its equipment are provided, including a housing chamber, A detection device, a sampling device, an analysis device, a reaction device 26 and a controller, the detection device is configured to detect the detection oil sample stored in the accommodating cavity; the sampling device is configured to be used in conjunction with the detection device, And carry out sampling and detection to the detection oil sample; The analysis device is configured to analyze the results of the detection device and the sampling device; The reaction device 26 is configured to collect the detection oil sample And discriminating substances in the detected oil sample; the detection device, the sampling device, the analysis device and the reaction device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com