Automatic feeding device for contact pin

A technology of automatic feeding and pin insertion, which is applied in the assembly/disassembly of contact parts, can solve problems such as low efficiency, achieve the effect of reducing assembly cycle, reducing labor intensity, and meeting the needs of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

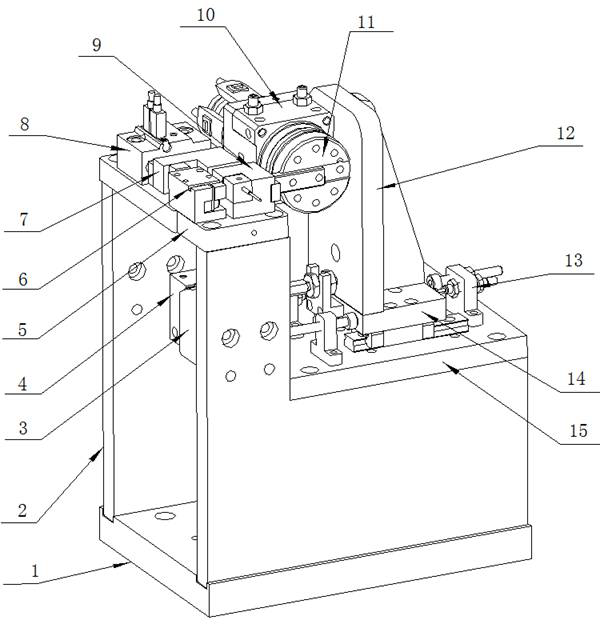

[0025] Embodiment 1: as figure 1 , the automatic feeding device of the present invention, base plate 1, support plate 2, horizontal cylinder fixed plate 3, horizontal cylinder 4, feeding fixed plate 5, feeding flow channel 6, top plate 7, feeding cylinder 8, feeding finger 9 , Rotary cylinder 10, rotary flange 11, rotary cylinder fixed plate 12, limit block 13, slide plate 14, fixed plate 15.

[0026] The feeding flow channel 6 and the feeding cylinder 8 are installed on the feeding fixed plate 5, and the feeding fixed plate 5 is installed on the top of two stepped support plates 2, and the two stepped support plates 2 are fixed on the bottom plate 1, and the two A fixed plate 15 is installed on the second step surface of a stepped support plate 2, a horizontal cylinder 4 is installed between two stepped support plates 2, the horizontal cylinder 4 is connected with the sliding mechanism on the fixed plate 15, and the rotary cylinder 10 is installed on the sliding On the slide...

Embodiment 2

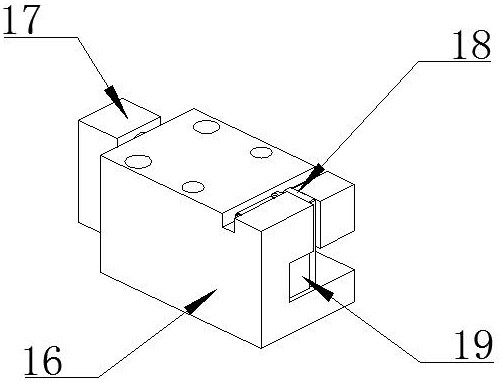

[0032] Embodiment 2: (The difference from Embodiment 1 is that the card sheet 18 does not use a spring to reset, but directly uses a cylinder to reset)

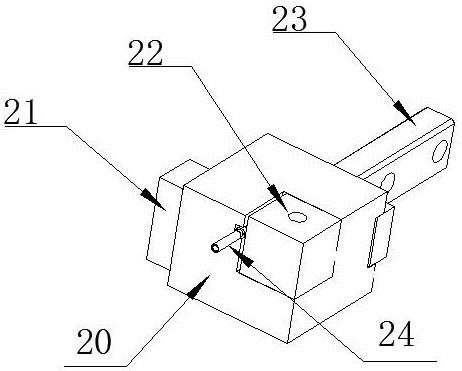

[0033] The feeding flow channel 6 and the feeding cylinder 8 are installed on the feeding fixed plate 5, and the feeding fixed plate 5 is installed on the top of two stepped support plates 2, and the two stepped support plates 2 are fixed on the bottom plate 1, and the two A fixed plate 15 is installed on the second step surface of a stepped support plate 2, a horizontal cylinder 4 is installed between two stepped support plates 2, the horizontal cylinder 4 is connected with the sliding mechanism on the fixed plate 15, and the rotary cylinder 10 is installed on the sliding On the slide table of mechanism, material fetching finger 9 is installed on the rotating flange 11 by arm 23, and fetching material finger 9 just in time is placed on the feeding fixed plate 5 when arm 23 turns to level.

[0034] Fixed plate 15 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com