Half-shell-opening melon seed stir-frying process

A technology for frying melon seeds and melon seeds, which is applied in the fields of shelling, application, food processing, etc., can solve the problems of inability to realize recycling, excess seasoning, and low efficiency of raw material use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

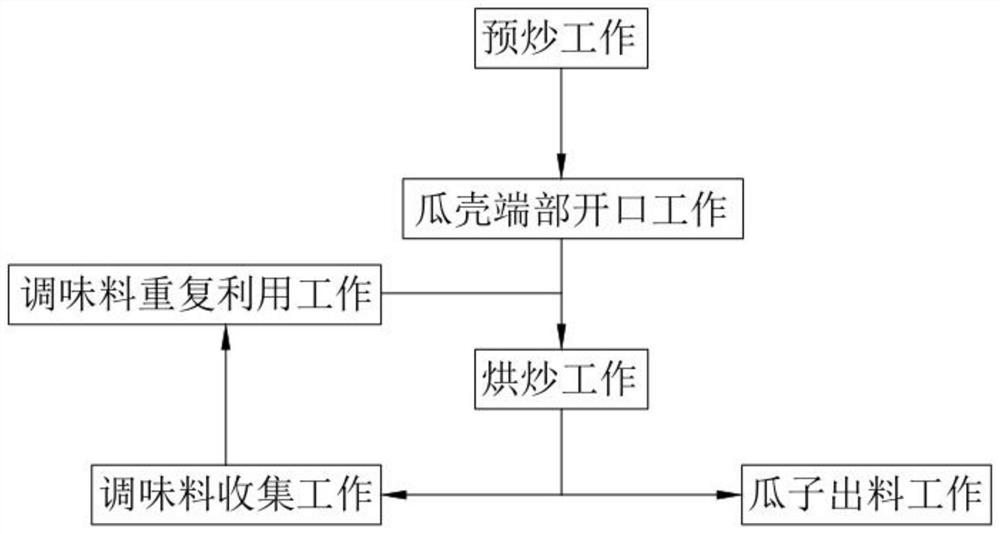

[0095] Such as figure 1 As shown, a kind of frying melon seeds process for half-opening shells, including:

[0096] Step 1, pre-frying work, pour melon seeds 100 into the first boiler 11 and perform pre-frying work through the first stirring component 12, and part of the melon seeds quantitatively enter the feeding area 20a driven by the lower part through the feeding port 40;

[0097] Step 2: The end of the melon shell is opened, and the roller 21 of the opening mechanism 2 drives the feed member 201 to rotate to the discharge port 40 to carry out the quantitative feeding work, and the quantitative melon seeds are dropped into the extruding member 222, and then the blade is used to 203 Cut the upper end of the melon seeds in the extruding part 222 and cooperate with the second protruding block 2224 of the transmission to cooperate with the first protruding block 206 on the push rod 204 to complete the extruding and cracking of the melon seeds after the incision;

[0098] Ste...

Embodiment 2

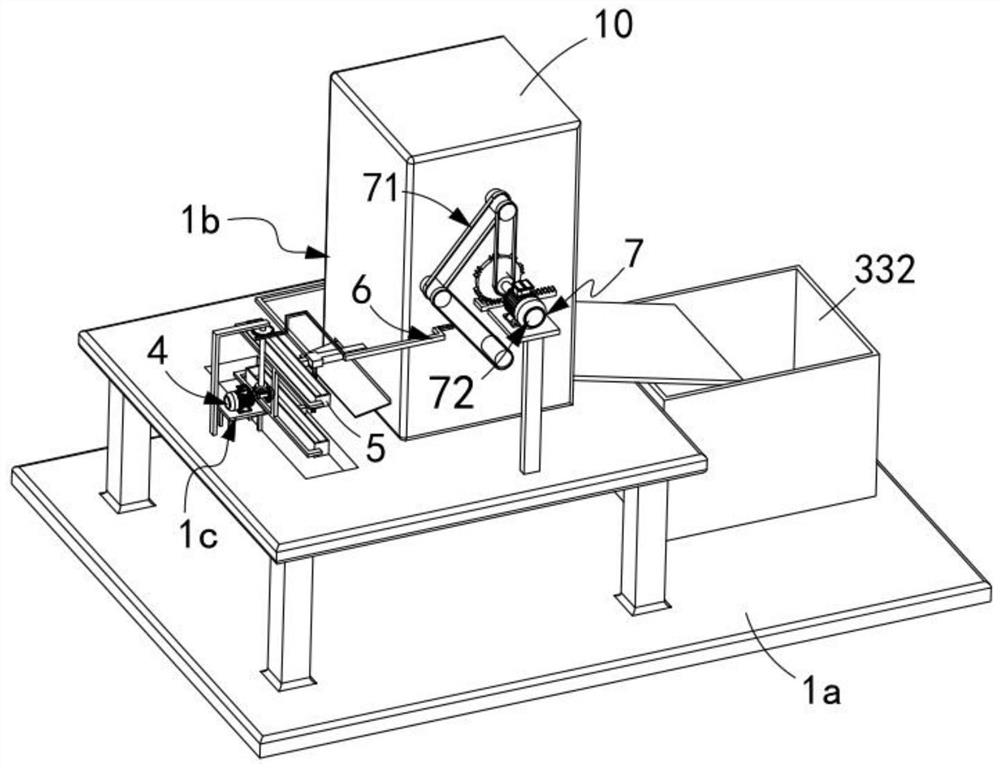

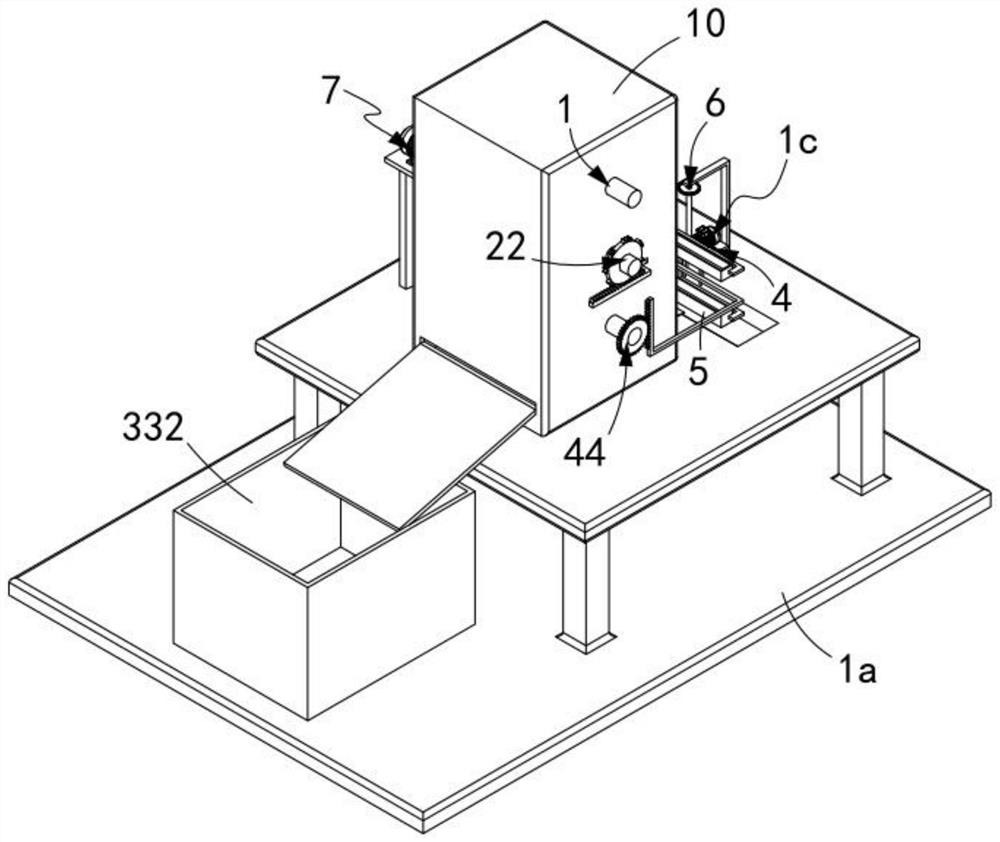

[0114] Such as Figure 2 to Figure 4 As shown, a device for frying melon seeds with half-open shells includes a shell 10 installed on a frame 1a, a frying mechanism 1b inside the shell 10, and a seasoning cycle arranged outside the shell 10 Institution 1c;

[0115] The frying mechanism 1b includes a first stir-frying mechanism 1, an opening mechanism 2, and a second stir-frying mechanism 3 located in the housing 10 and arranged vertically from top to bottom; the first stir-frying mechanism 1 Including the first boiler 11, the first stirring assembly 12 arranged in the first boiler 11, and the control assembly synchronously driven with the first stirring assembly 12 and used to control the quantitative discharge of the output end of the first boiler 11 13. The opening mechanism 2 includes a rotating roller 21 rotatably arranged on the housing 10 and a blanking assembly 22 arranged below the rotating roller 21 and horizontally slidingly arranged in the housing 10. The rotating ...

Embodiment 3

[0168] Such as Figure 23 to Figure 29 As shown, the parts that are the same as or corresponding to those in the second embodiment are marked with the corresponding reference numerals in the second embodiment. For the sake of simplicity, only the differences from the second embodiment will be described below. The difference between this embodiment three and embodiment two is:

[0169] further, such as Figure 23 to Figure 29 , the blanking assembly 22 includes:

[0170] A screening plate 221, the two ends of the screening plate 221 are slidably arranged in the first sliding track 2212 of the housing 10 through the third telescopic unit 2211, the screening plate 221 is provided with an extrusion part 222, the extrusion The pressing part 222 includes a placement hole 2221 arranged on the screening plate 221 and a pressing plate 2223 installed on the screening plate 221 through a second telescopic unit 2222, and a first pressing plate 2223 is arranged above the pressing plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com