Food processor and control method thereof

A technology of a food processing machine and a control method, which is applied in the direction of stopping devices, kitchen utensils, household utensils, etc., which can solve problems such as loud noise, rapid motor stop, accidental injury, etc., and achieve low noise and vibration, and small control torque pulsation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

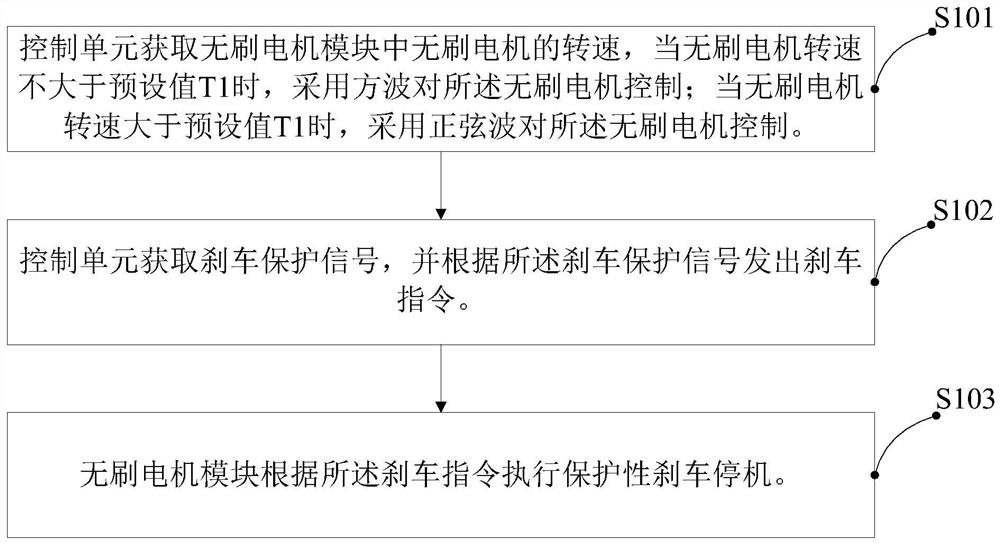

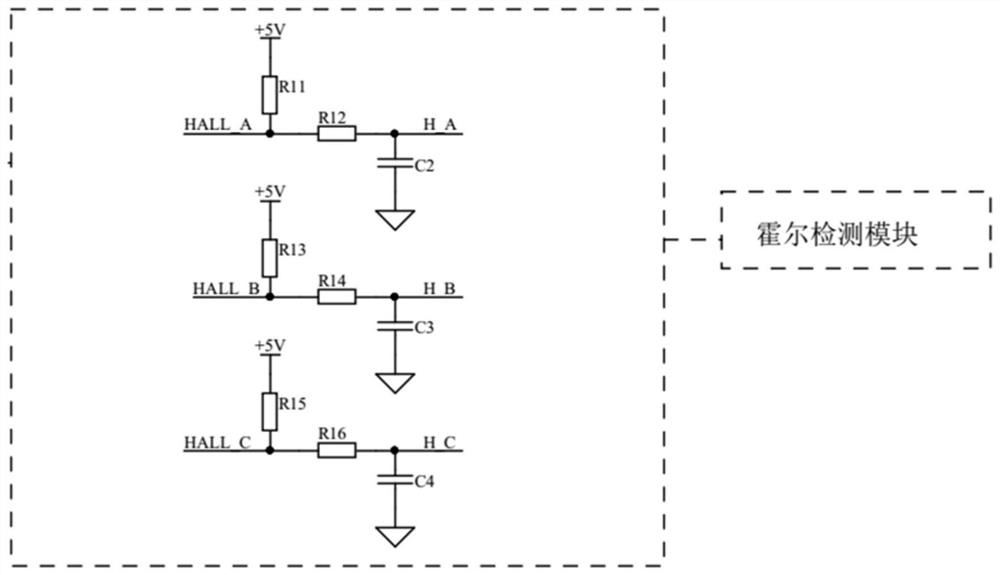

[0044] combine Figure 1 to Figure 5 As shown, the first embodiment of the present invention provides a method for controlling a food processing machine. The food processing machine includes a brushless motor module for stirring and pulverizing materials, a control unit for controlling the brushless motor module, and a Hall detection module. The control method of the processing machine includes the following steps:

[0045] Step S101: the control unit obtains the speed of the brushless motor in the brushless motor module, and when the speed of the brushless motor is not greater than the preset value T1, the brushless motor is controlled by using a square wave; when the speed of the brushless motor is greater than the preset value At T1, a sine wave is used to control the brushless motor.

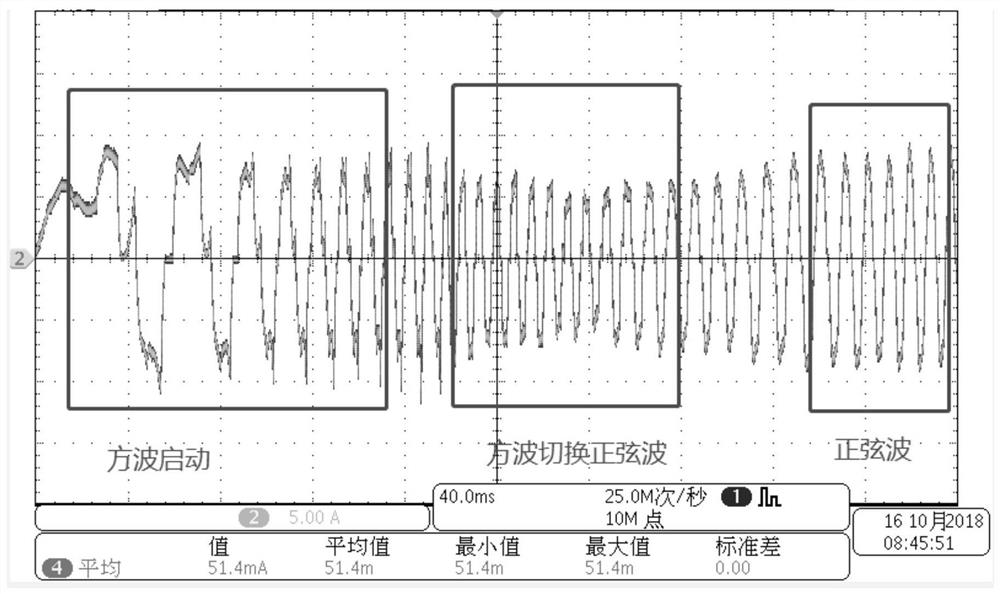

[0046] Such as Figure 3 to Figure 5 As shown, when the food processor is started, a large torque is required to provide a large power to start, so this embodiment adopts square wave contr...

Embodiment 2

[0052] In this embodiment, the brake protection module includes a lid opening detection module, and the food processor detects the opening state of the lid of the stirring cup through the lid opening detection module, wherein the opening state of the lid of the stirring cup includes an open state and a closed state. Such as Figure 6 As shown, the control method of the food processing machine includes the following steps:

[0053] Step S201: The control unit detects the opening state of the lid of the blender cup, and the opening state includes an open state and a closed state.

[0054] When the food processor is working, the lid of the blender cup may be open due to improper installation or human error. The control unit in the embodiment of the present application detects the opening state of the lid of the stirring cup during the working process of the food processor through the lid opening detection module, and performs corresponding operations according to the opening sta...

Embodiment 3

[0058] In this embodiment, the brake protection module includes a zero-crossing detection module, and the food processing machine obtains the power-on state of the food processing machine through the zero-crossing detection module, and the power-on state includes an on state and an off state, such as Figure 7 As shown, the control method of the food processing machine includes the following steps:

[0059] Step S301: the control unit detects the power-on state of the food processor, and the power-on state includes an on state and an off state.

[0060] Such as Figure 8 As shown, the zero-crossing detection module includes an input terminal and an output terminal, and the input terminal and the output terminal are isolated by an optocoupler. There is a phototransistor for receiving the signal from the light-emitting diode U1. When the food processor is working, when the mains power is in the positive half cycle, the optocoupler light-emitting diode U1 is turned on, the photot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com