Pressing rod device for spinal deformity correction operation

A spinal deformity and rod pressing technology, which is applied in the directions of surgery, medical science, internal bone synthesis, etc., to achieve the effect of reducing the difficulty of operation, convenient use and simplifying steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

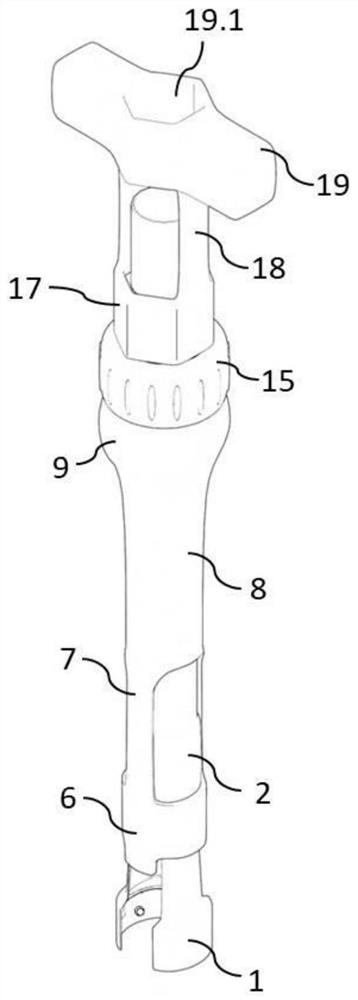

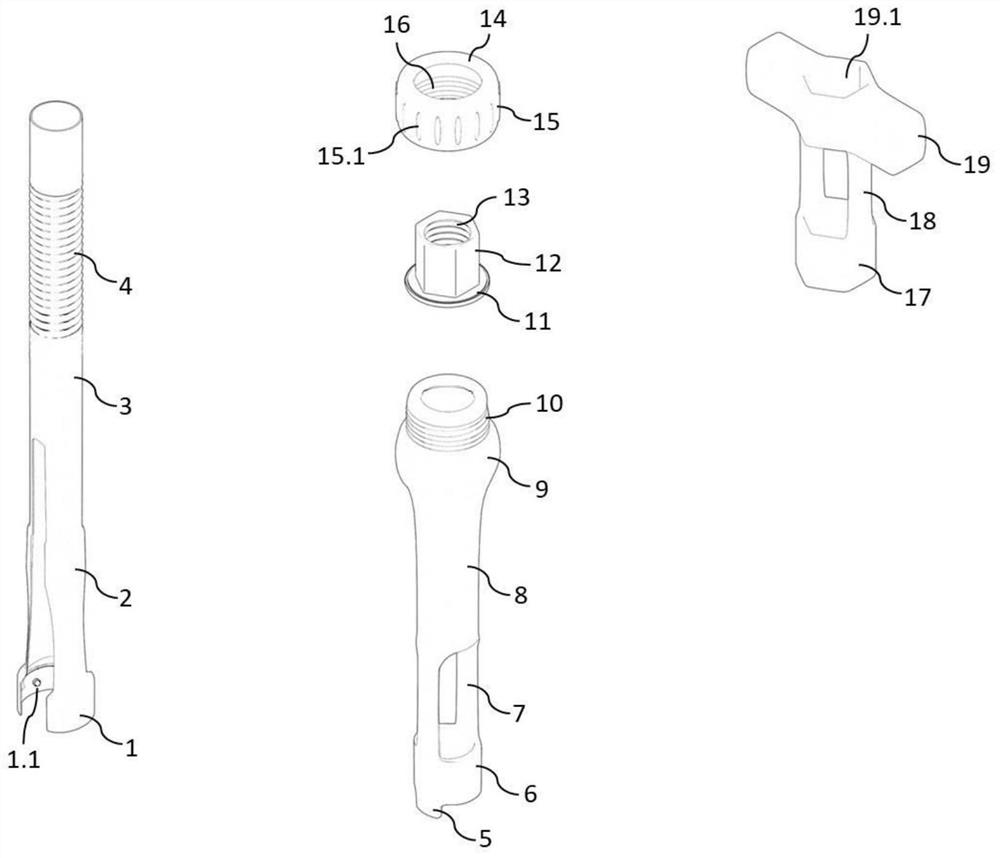

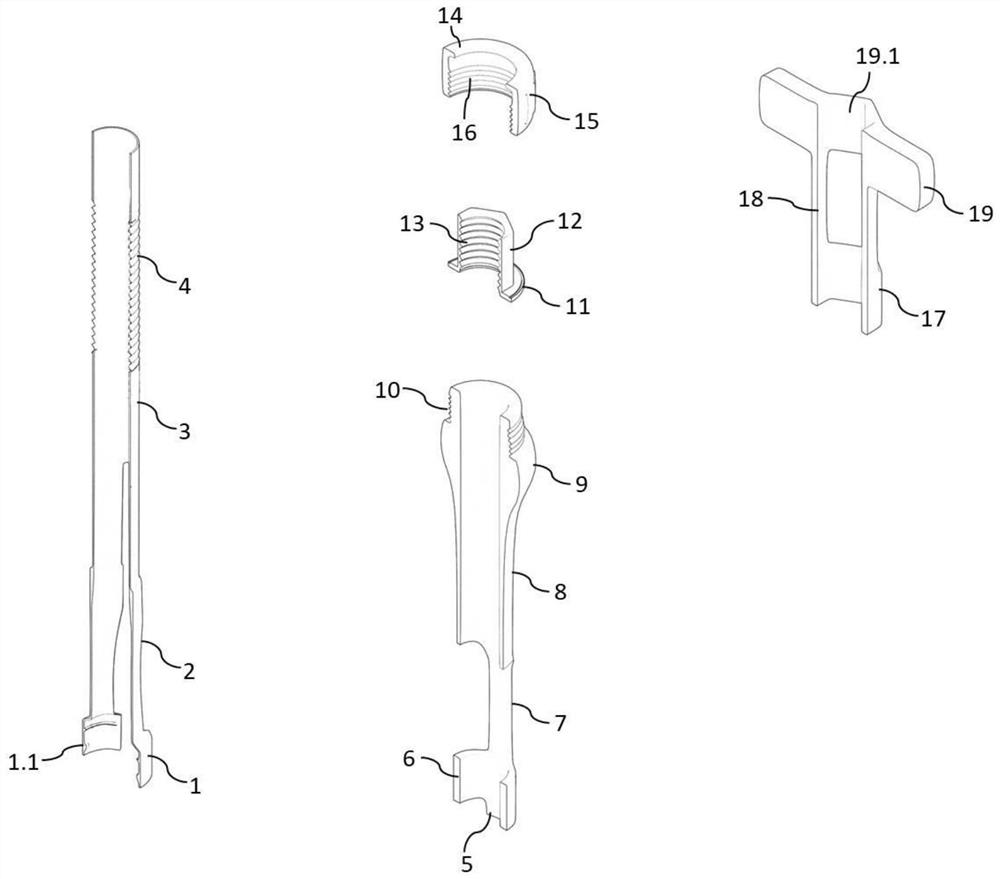

[0026] Embodiment 1: see Figure 1-Figure 4 , a compression rod device used for spinal deformity correction surgery, the compression rod device is composed of an inner tube, an outer tube, a rotating inner nut, a fixed outer nut and a matching T-shaped adjustment wrench. When in use, the inner tube, outer tube, rotating inner nut, and fixed outer nut are combined to form the main body of the pressing rod device, and then adjusted by the matching T-type wrench. In this scheme, if Figure 1-Figure 4 As shown, the inner tube includes a fixed claw 1, a lower bifurcated section 2, an inner tube body 3 and an upper external thread area 4, the fixed claw 1 is located below the lower bifurcated section 2, and the inner walls on both sides of the fixed claw have circles. Shaped protrusions 1.1. When in use, the protrusion is combined with the circular groove on the outer wall of the screw tail to play a fixed role. The fixed claws 1 on both sides extend upward to form the lower bifur...

Embodiment 2

[0032] Example 2: see Figure 1-Figure 4 , when the rod pressing device is assembled, the rotating inner nut is first placed on the top of the outer tube, the upper snap ring 14 of the fixed outer nut is pressed against the lower snap ring 11 of the rotating inner nut, and then the inner thread 16 of the fixed outer nut is connected with the The outer thread 10 on the top of the outer pipe is combined by rotation, and the outer pipe, the rotating inner nut and the fixed outer nut are combined into a whole. Then the inner pipe is inserted upwards from the lower end of the outer pipe, and then the outer thread 4 on the upper part of the inner pipe is combined with the inner thread 13 of the rotating inner nut to complete the assembly of the main body of the pressing rod device. During use, the fixed ring 17 of the T-type wrench is sleeved on the rotating inner nut body. Since the two are matching hexagonal appearance, the inner nut can be turned and rotated by twisting a T-type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com