Dehairing mechanism and device

A shaving and scraping technology, which is used in the processing of textile material equipment configuration, filtration and separation, fixed filter element filter, etc. The effect of cracking, increasing the pressing force and solving the blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

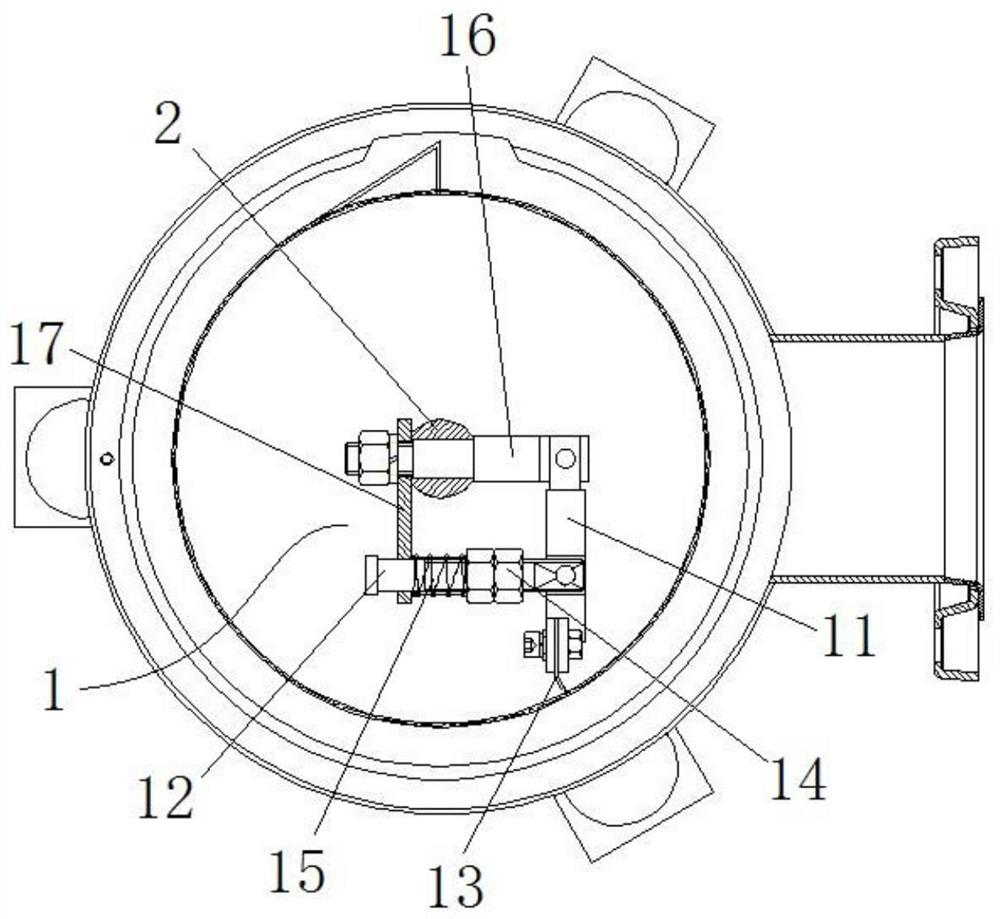

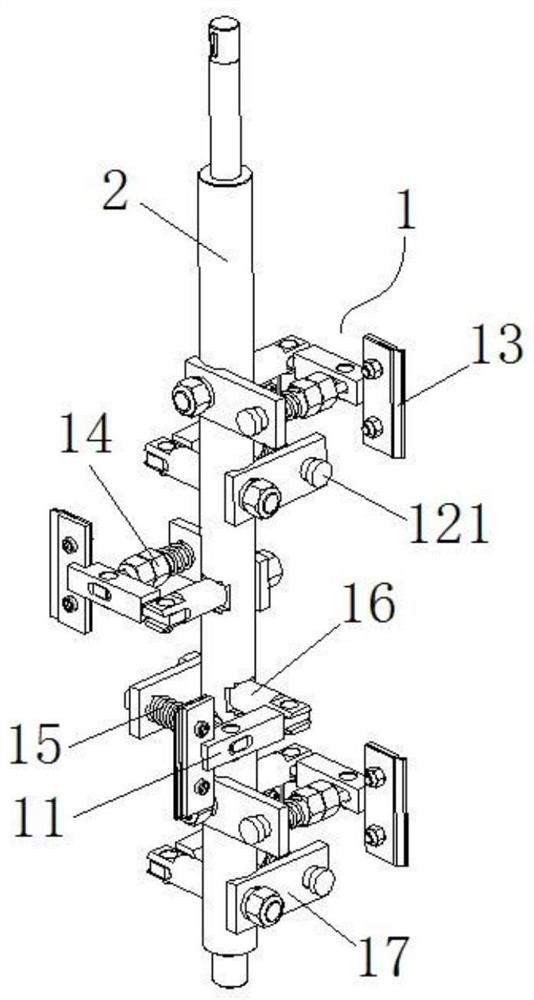

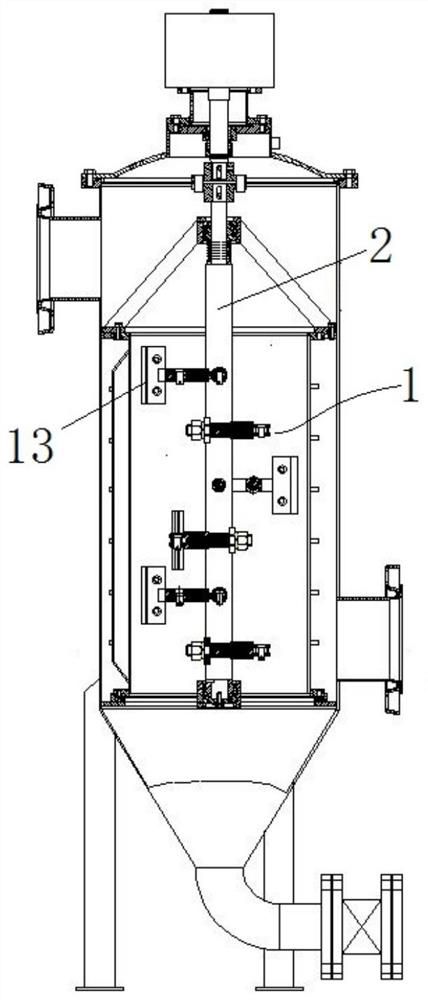

[0026] Such as Figure 1-3 As shown, a shaving mechanism 1 is provided in this embodiment, which mainly includes a scraper arm 11 and a guide column 12 . One end of the scraper arm 11 is directly or indirectly hingedly arranged on the main rotating shaft 2, the other end of the scraper arm 11 is provided with a scraper blade 13; one end of the guide post 12 is hingedly arranged on the scraper arm 11 , the other end of the guide column 12 is directly or indirectly arranged on the main rotating shaft 2 in a relatively slidable manner.

[0027] Wherein, the guide post 12 is provided with a position-adjustable adjustment member 14 , and a spring 15 is sheathed on the guide post 12 between the adjustment member 14 and the main rotating shaft 2 directly or indirectly.

[0028] As a preferred solution, in this embodiment, a scraper shaft 16 is provided corresponding to the scraper arm 11, and one end of the scraper shaft 16 is arranged on the main rotating shaft 2 and fixed by a fas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com