Pigment and filler slurry mixing device and method

A mixing device and technology of pigments and fillers, applied in the field of pigments and fillers, can solve the problems of paint coloring power, hiding power, gloss strength and other properties not meeting the requirements, large material particle size, low friction coefficient, etc., to achieve enhanced dispersion and emulsification effect, high gloss, high dispersion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

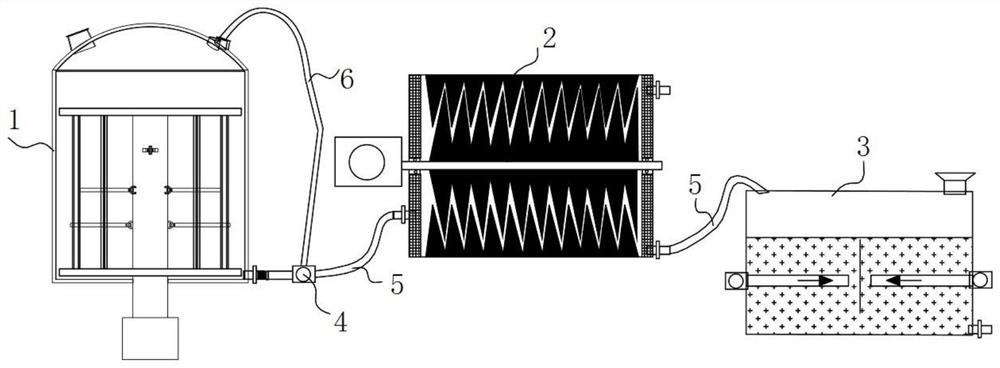

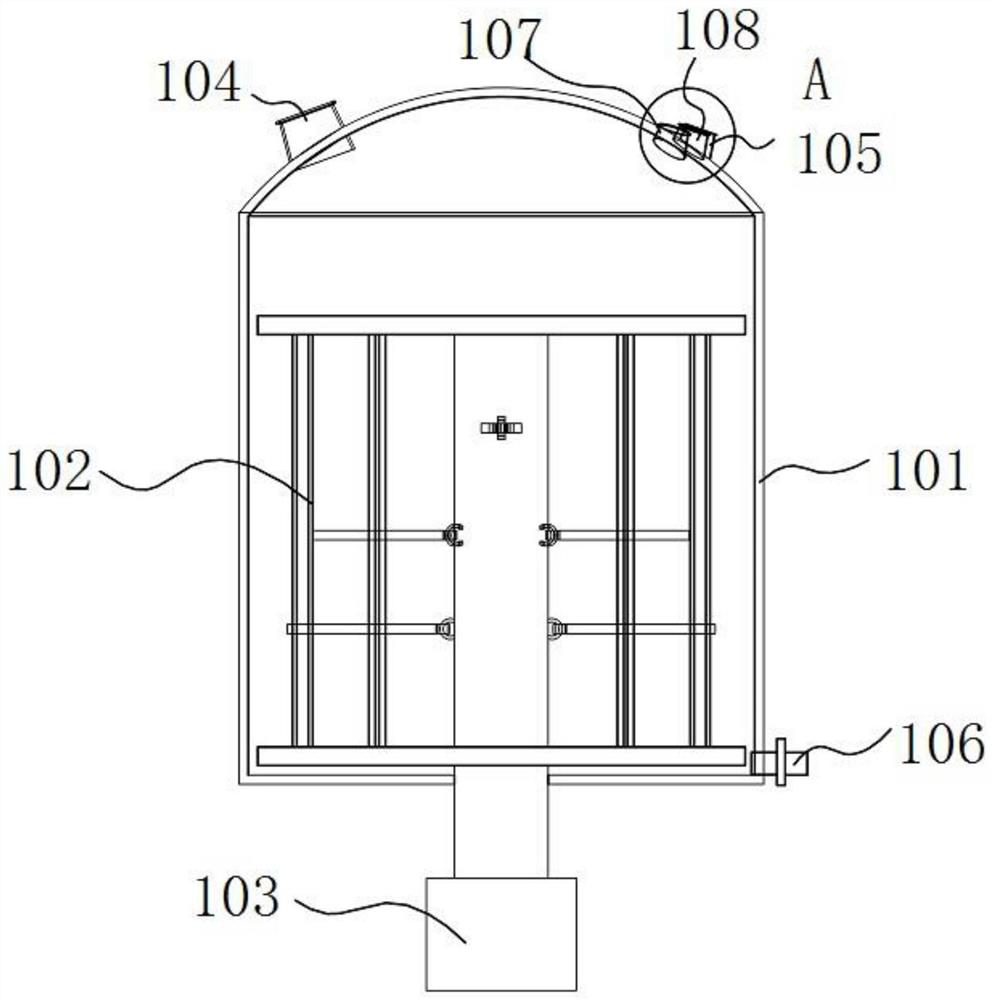

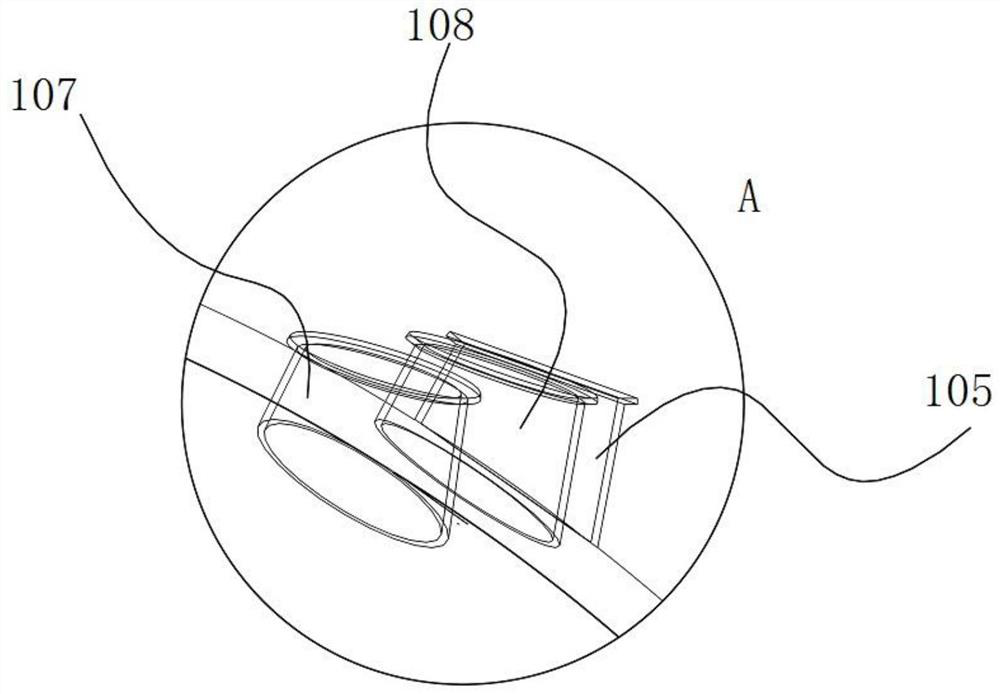

[0042] like Figures 1 to 7 As shown, a kind of pigment slurry mixing device comprises a stirring mixer 1, an extrusion mixer 2 and an impact mixer 3, the stirring mixer 1 includes a cylinder 101, and a stirring frame 102 is installed in the cylinder 101, and the stirring frame 102 Driven by the motor I103, the motor I103 drives the stirring frame 102 to rotate forward or reversely, and rotate and stir in the stirring mixer 1 according to the different speeds, so that turbulent flow can be generated between the additives and the original paint pigments and fillers, which is convenient for paint The mixing of pigments and fillers and additives; the extrusion mixer 2 is connected with the agitating mixer 1 through the delivery pipeline 5 and the pressure pump 4, the extrusion mixer 2 includes the meshed ring gear cylinder 201 and the gear shaft 202, and the gear shaft 202 is composed of When the motor II 203 is driven, the motor II 203 drives the gear shaft 202 to rotate forward...

Embodiment 2

[0052] like Figures 1 to 8 Shown, another aspect of the present invention also provides a kind of pigment filler slurry mixing method, specifically comprises the following steps:

[0053] Stirring and mixing: According to the proportion of pigment and filler slurry determined by the formula, add it from the feed port I104 of the stirring mixer 1, determine the stirring parameters, and take samples from the detection port I105 after stirring and mixing to determine the quality of the pigment and filler slurry;

[0054] Extrusion mixing: under the action of the pressure pump 4, the mixed pigment and filler slurry enters the extrusion mixer 2 from the feed port II 206, the motor II 203 drives the gear shaft 202 to rotate, and the pigment and filler slurry passes through the ring gear cylinder 201 and the gear shaft 202 After extrusion and mixing, samples are taken from the detection port Ⅱ204 to determine the quality of the pigment and filler slurry. If the quality requirements ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com