Assembly block for high-temperature and high-pressure modification of CVD cultivated diamond and modification method

A high-temperature, high-pressure, diamond technology, which is applied in the direction of using atmospheric pressure to chemically change substances, chemical instruments and methods, and components of pressure vessels, can solve crystal defects, non-diamond crystal structure defects, and diamonds that are difficult to achieve clarity. Standards and other issues to achieve the effect of improving color and transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: A CVD-grown diamond assembly block for high-temperature and high-pressure modification

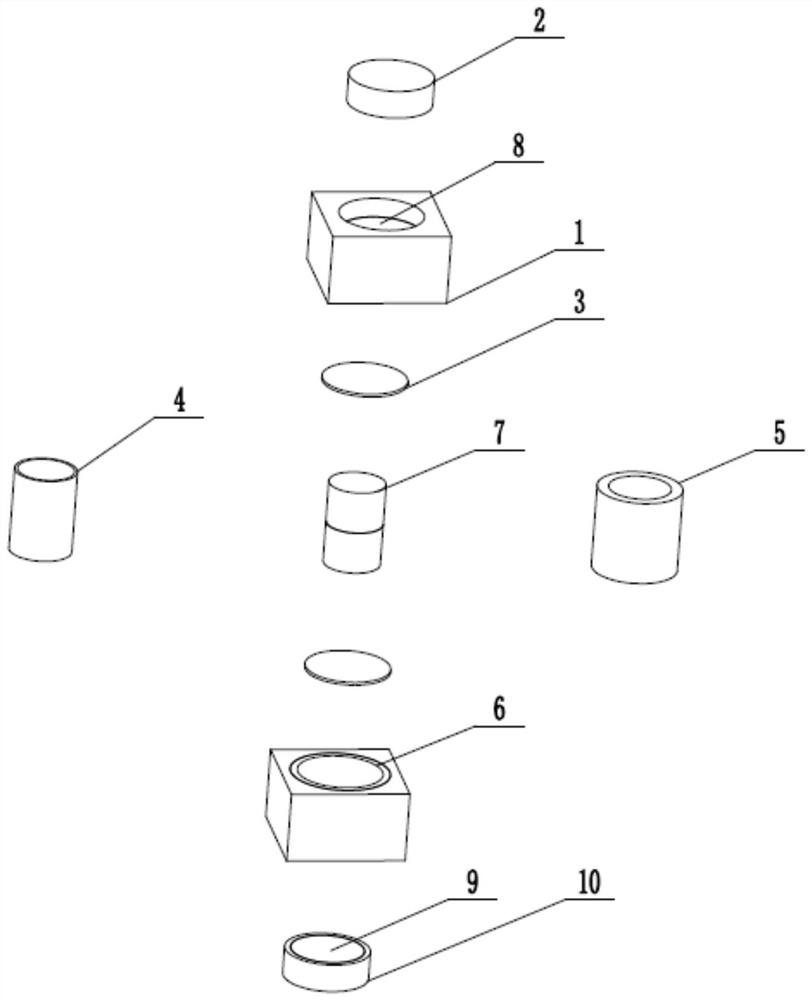

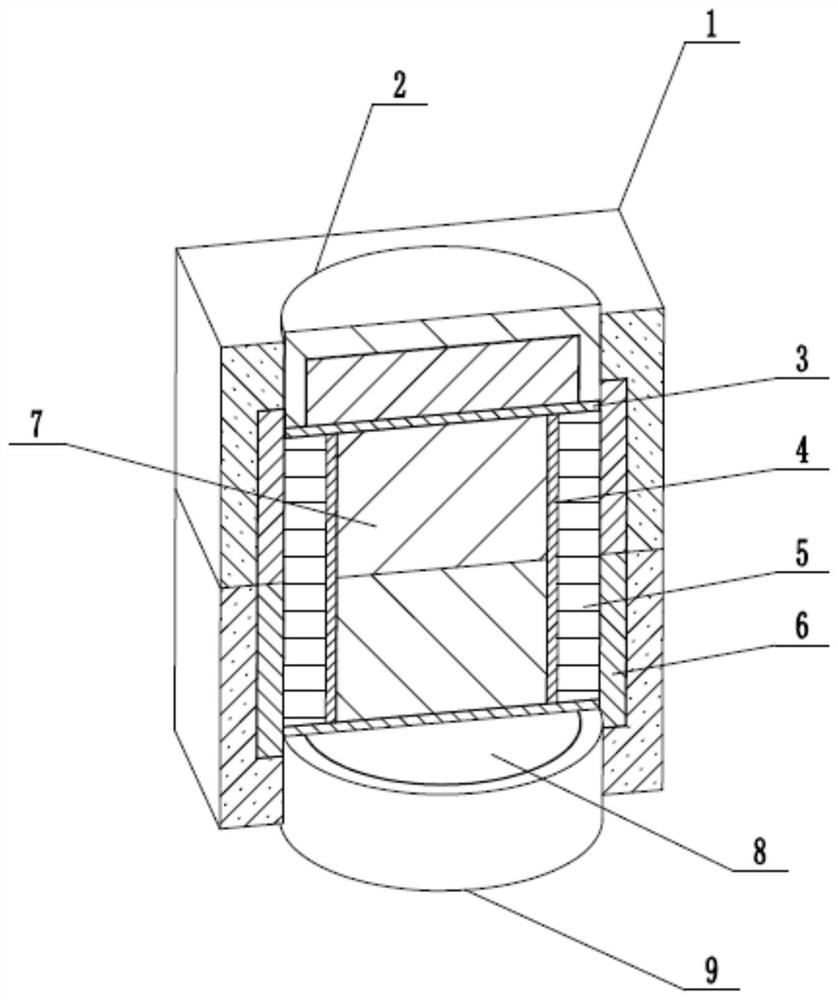

[0036] It includes a pyrophyllite block 1, a conductive cap 2, a heating sheet 3, a heating pipe 4, a first heat preservation pipe 5, a second heat preservation pipe 6, and a heat preservation column 7.

[0037] The pyrophyllite block 1 is located at the outermost periphery and is a pressure transmission and sealing medium, which can transmit the pressure on the top hammer of the high-temperature and high-pressure synthesis press to the inside of the assembly block, and at the same time has a certain sealing effect, which can seal the inside of the assembly block. Pressure, to ensure the safety of high temperature and high pressure modification. The pyrophyllite block 1 is centered and has a cylindrical installation cavity 8 that penetrates up and down. The remaining components include conductive cap 2×2, heating plate 3×2, heating pipe 4×1, first heat preservation pipe ...

Embodiment 2

[0046] Example 2: A CVD-grown diamond assembly block for high-temperature and high-pressure modification

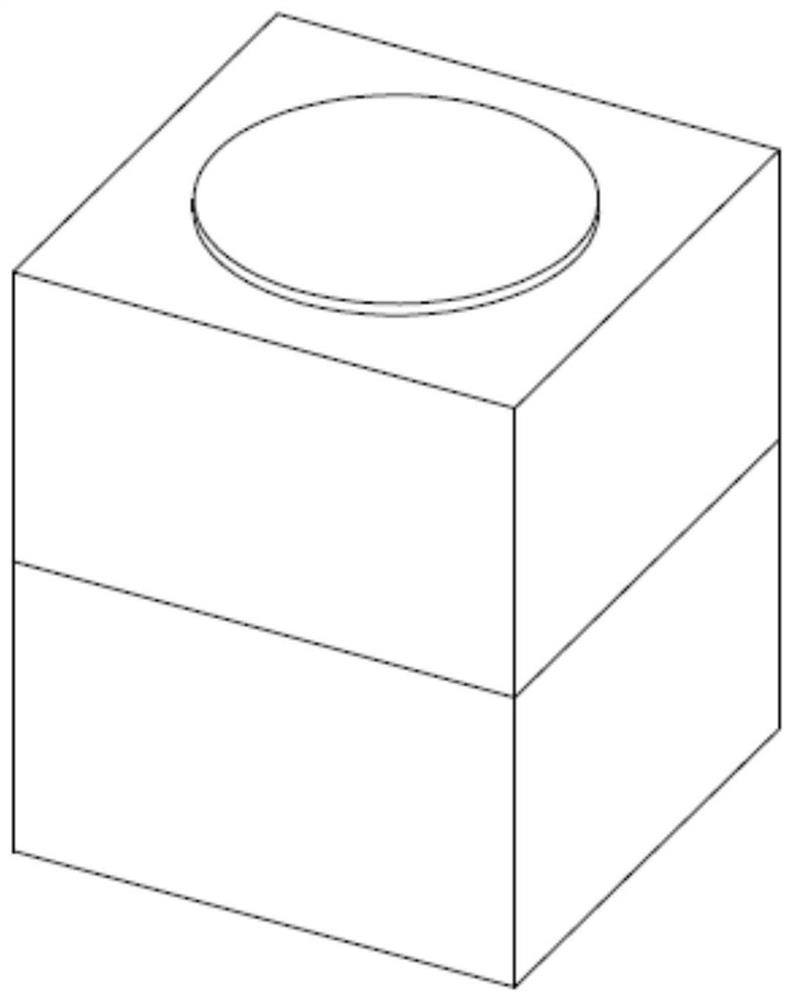

[0047] Most of the structure of the assembly block is the same as that of Embodiment 1, and the difference between the two examples lies in the specific structure of the pyrophyllite block 1 and the materials used for each component.

[0048] 1) The structure of the pyrophyllite block 1: In this example, the pyrophyllite block adopts a structure divided into upper and lower stone blocks, which is convenient for assembly.

[0049] 2) Materials used for conductive cap 2, heating plate 3, heating pipe 4, first heat preservation pipe 5, second heat preservation pipe 6, and heat preservation column 7:

[0050] The metal bowl 10 of the conductive cap 2 is made of titanium gold; the filler core 9 of the conductive cap 2 is made of alumina ceramic material;

[0051] The heating sheet 3 and the heating tube 4 use artificial carbon;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com