A kind of thymol microcapsule based on starch wall material and preparation method thereof

A technology of thymol and microcapsules is applied in the field of preparation of high-purity V-type starch carriers, can solve the problems of decreased V-type crystalline content, unfavorable V-type starch loading, etc., and achieves short time consumption, simple equipment and preparation process, and high technology. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

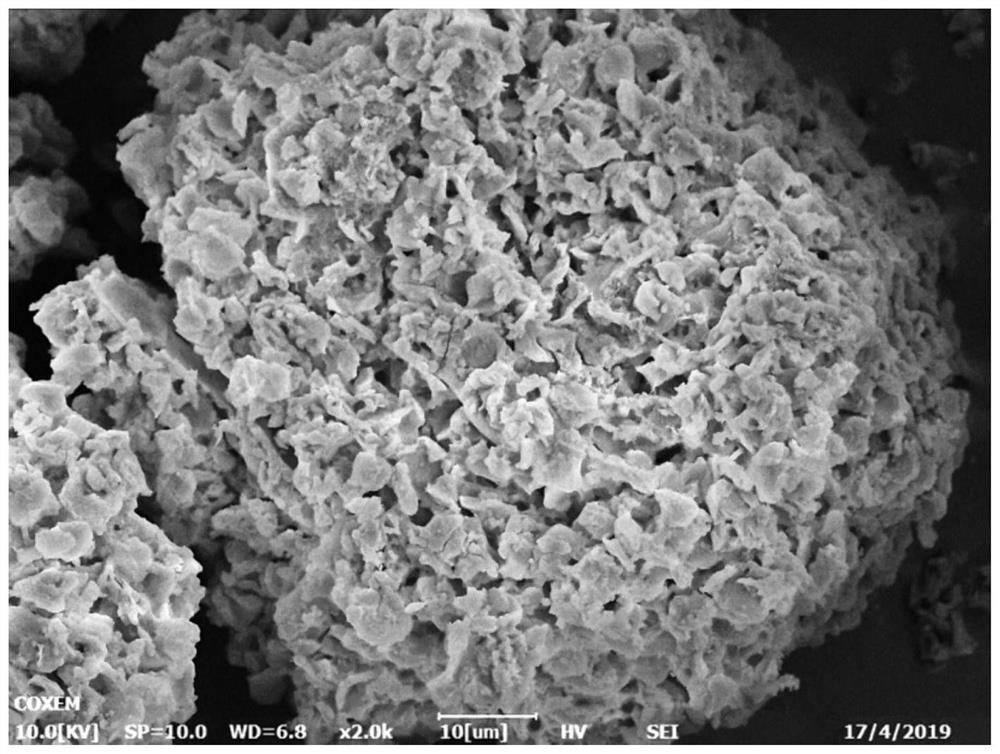

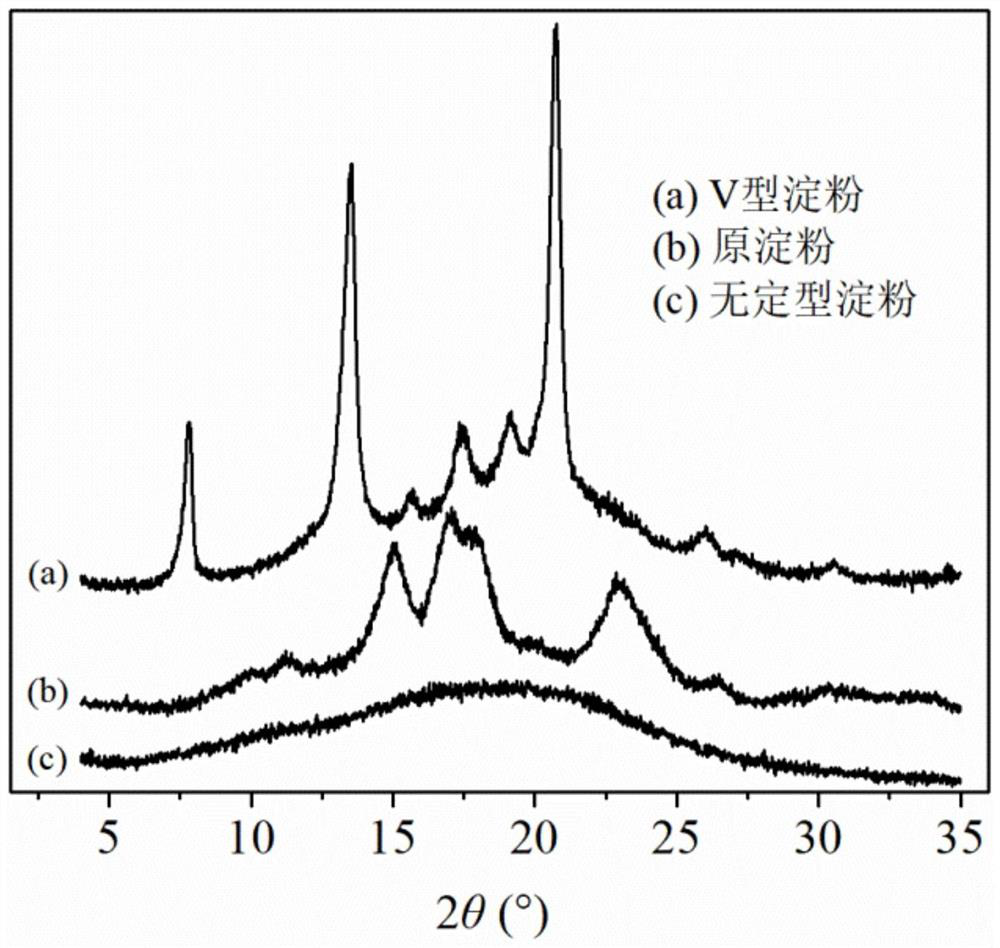

[0040] (1) Preparation of high-purity V-type starch

[0041] a) Disperse 10 g of waxy cornstarch in 200 mL of distilled water, stir and heat in a boiling water bath for 60 min; cool and keep at 55 ° C, add 0.5 g of pullulanase (purchased from Sigma-Aldrich Company), stir, and carry out enzymatic hydrolysis reaction for 24 h , to obtain the debranched starch liquid, and place it in a rotary evaporator, and concentrate to 100mL;

[0042] b) treating the concentrated debranched starch solution in step a) at 170°C for 30 minutes;

[0043] c) Cool the debranched starch solution obtained in step b) to 80°C, add the debranched starch liquid dropwise to 5 times the volume of absolute ethanol, then centrifuge, dry in an oven at 50°C for 3 hours, and pulverize to obtain Type V starch.

[0044] (2) Microcapsules prepared by embedding thymol in V-type starch:

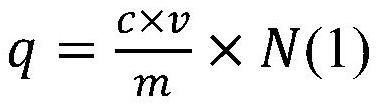

[0045] Put 2g V-type starch and 0.2g thymol in a mortar, manually grind the mixed sample at an average speed of 90r / min for 8m...

Embodiment 2

[0050] (1) Preparation of high-purity V-type starch

[0051] a) Disperse 15g of waxy cornstarch in 150mL of distilled water, stir and heat in a boiling water bath for 40min; cool and keep at 55°C, add 0.4g of pullulanase, stir, and carry out enzymatic hydrolysis reaction for 24h to obtain debranched starch liquid, and Put it in a rotary evaporator and concentrate to 100mL;

[0052] b) treating the concentrated debranched starch solution in step a) at 160° C. for 30 minutes;

[0053] c) Cool the debranched starch solution obtained in step b) to 60° C., add 4 times the volume of absolute ethanol dropwise to the debranched starch solution, then centrifuge, freeze-dry, and pulverize to obtain high-purity V-type starch.

[0054] (2) Microcapsules prepared by embedding thymol in V-type starch:

[0055] Put 5g V-type starch and 0.5g thymol in a mortar, manually grind the mixed sample at an average speed of 60r / min for 5min, put it into a ziplock bag and shake it fully for 2min, and...

Embodiment 3

[0058] (1) Preparation of high-purity V-type starch

[0059] a) Disperse 12g of waxy cornstarch in 240mL of distilled water, stir and heat in a boiling water bath for 60min; cool and keep at 55°C, add 0.6g of pullulanase, stir, and carry out enzymatic hydrolysis reaction for 24h to obtain debranched starch liquid, and Concentrate it in a rotary evaporator to 80 mL;

[0060] b) treating the concentrated debranched starch solution in step a) at 150° C. for 30 minutes;

[0061] c) Cool the debranched starch solution obtained in step b) to 80° C., add 4 times the volume of absolute ethanol dropwise to the debranched starch solution, then centrifuge, naturally air-dry, and pulverize to obtain high-purity V-type starch.

[0062] (2) Microcapsules prepared by embedding thymol in V-type starch:

[0063] Put 3g V-type starch and 0.3g thymol in a mortar, manually grind the mixed sample at an average speed of 80r / min for 6min, put it into a ziplock bag and shake it fully for 3min, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| load ratio | aaaaa | aaaaa |

| embedding rate | aaaaa | aaaaa |

| embedding rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com