Cleaning device for chromatographic bottle for chemical laboratory

A technology for chemical laboratories and cleaning devices, applied in chemical instruments and methods, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problems of difficult cleaning of chromatographic bottles, low cleaning efficiency, etc., to improve cleaning effect and efficiency. , good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

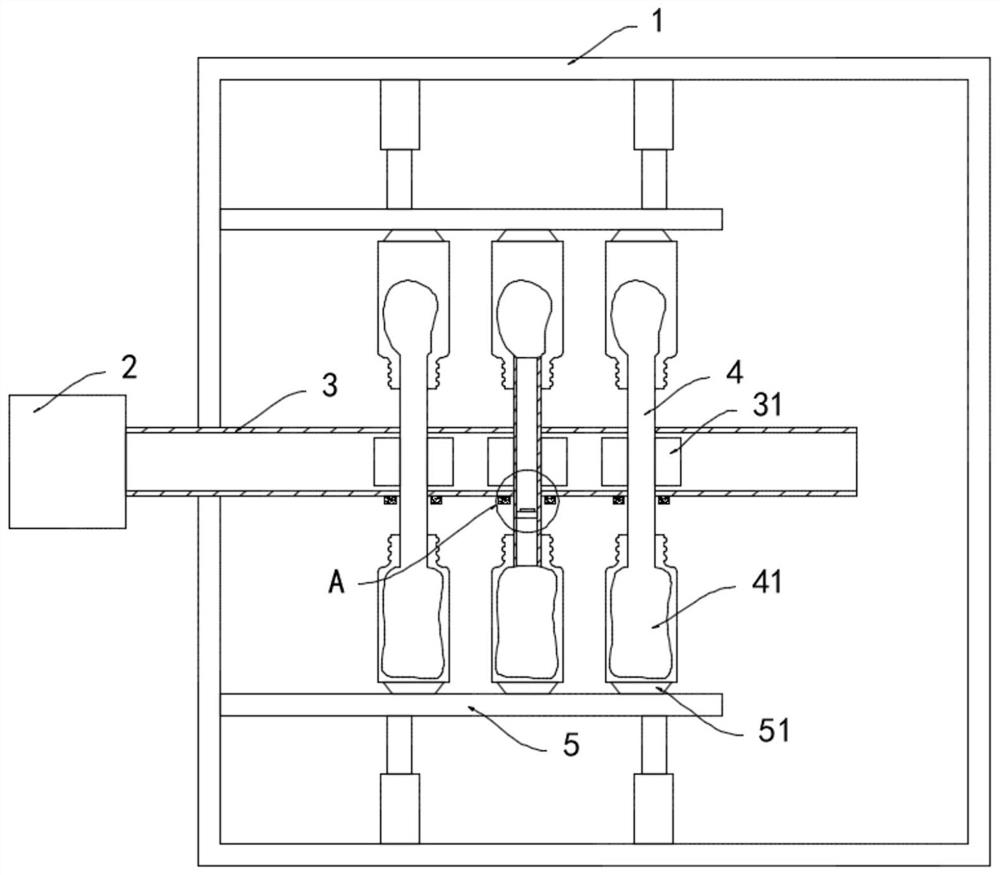

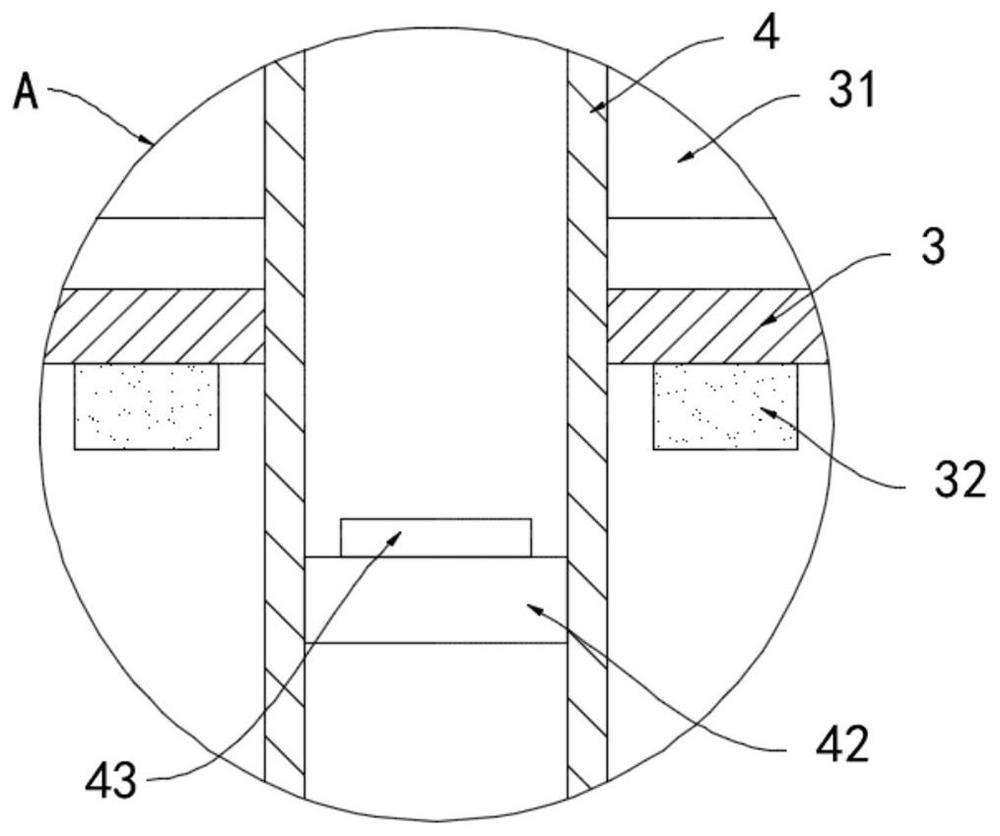

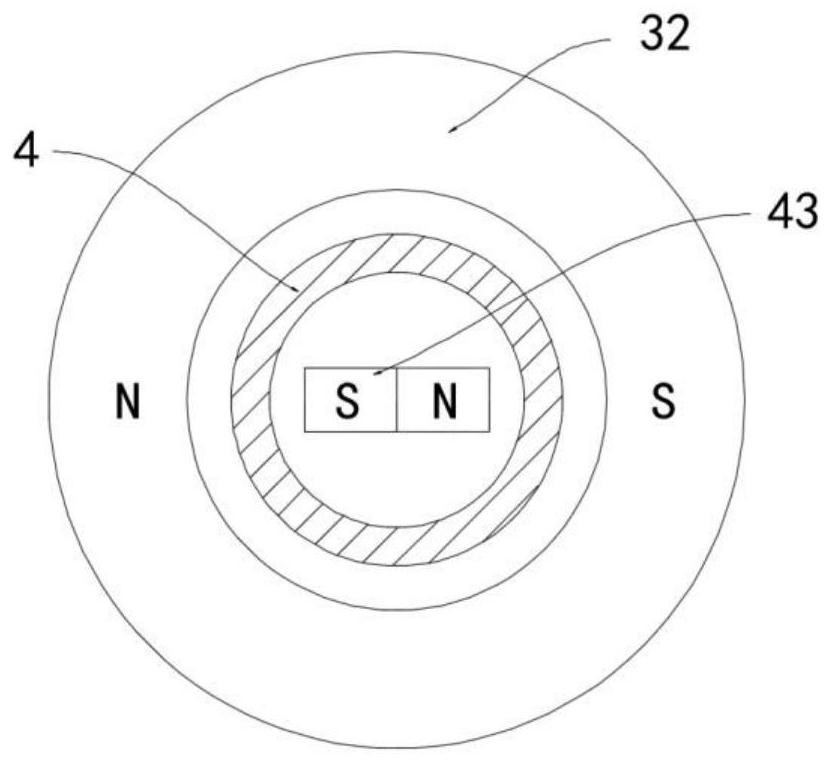

[0020] like Figure 1-3 As shown, a cleaning device for chromatographic bottles used in a chemical laboratory includes a cleaning tank 1 and a blower fan 2. A horizontal air pipe 3 is provided in the cleaning tank 1. One end of the air pipe 3 runs through the side wall of the cleaning tank 1 and connects with the blower fan 2. It is fixed and communicated. There are a plurality of rotating tubes 4 perpendicular to the axial direction running through the air pipe 3. The rotating pipes 4 are connected to the air pipe 3 in a sealed and rotating manner. The air pipe 3 is provided with a plurality of windward plates 31, which are installed in a circular array. On the side wall of the rotating tube 4, both ends of the rotating tube 4 are fixedly connected with a telescopic air bag 41, and the outer part of the telescopic air bag 41 is fixedly embedded with bristles. scrape off.

[0021] Piston block 42 is sealed and slidably connected in rotating tube 4, and bar magnet 43 is fixedl...

Embodiment 2

[0024] like Figure 4-5 As shown, the difference between the present embodiment and Embodiment 1 is that the impeller 6 is sleeved on the outside of the air pipe 3, and the blades of the impeller 6 are provided with exhaust passages 61 communicating with the air pipe 3, and a plurality of exhaust passages 61 are arranged along the The impeller 6 is radially arranged, and a plurality of exhaust holes 62 are opened on the side wall of the exhaust passage 61, and the opening directions of the plurality of exhaust holes 62 are consistent.

[0025] In this embodiment, the air in the air pipe 3 enters the exhaust channel 61 and is discharged through a plurality of exhaust holes 62. When the air flow is discharged, a reaction force along the axis direction of the exhaust holes 62 is provided to the impeller 6 to drive the impeller 6. Rotate to promote the flow of the cleaning liquid in the cleaning tank 1, avoiding the sewage carrying the stains to linger around the chromatographic b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com