Biomass and carbon-containing organic waste pyrolysis rotary furnace and pyrolysis product recovering system

A technology of organic waste and recycling system, applied in the fields of biofuels, rotary carbonization furnaces, coke ovens, etc., can solve problems such as the ineffective utilization of biomass, and achieve the effect of reducing operating costs and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

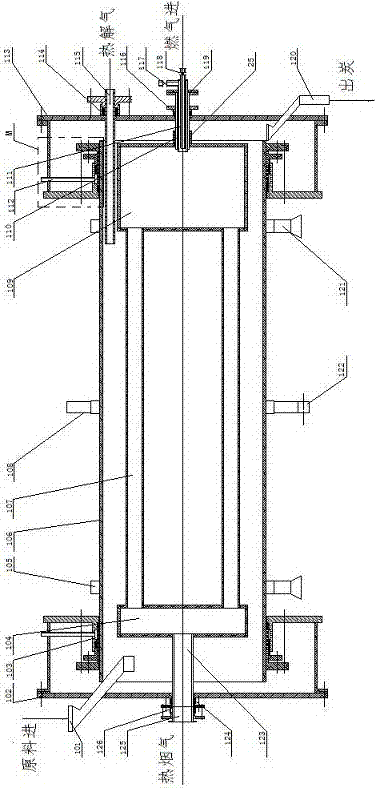

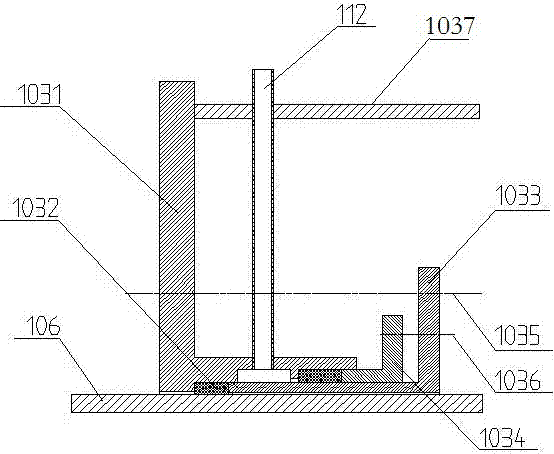

[0028] Such as figure 1A biomass and carbon-containing organic waste pyrolysis rotary furnace shown includes a cylindrical shell 106, and the outer wall of the shell 106 is connected with a support mechanism and a transmission mechanism, and the support mechanism includes at least two sets of coaxial The supporting ring 105 fixedly connected to the outer wall of the housing 106 and the support roller 121 rollingly connected to the outer wall of the supporting ring 105, the transmission mechanism includes a ring gear 108 coaxially fixedly connected to the outer wall of the housing 106, and the ring gear 108 meshes with the transmission gear 122, the gear 122 is connected to the output shaft of the reducer; the two ends of the housing 106 are respectively connected to the burner head cover 102 and the furnace tail cover 113 through the gas-sealed double seal assembly 103, and the housing 106 A flue gas collection chamber 104 is provided on the furnace head side of the inner cavi...

Embodiment 2

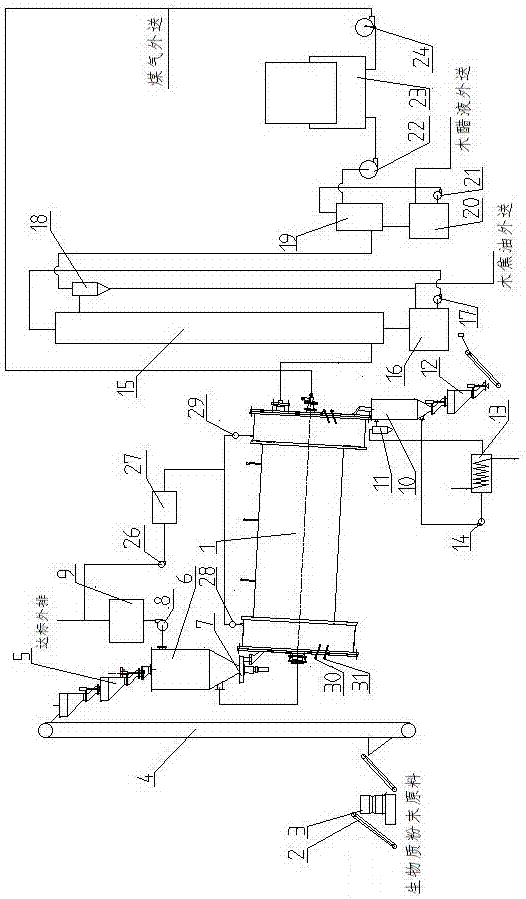

[0034] Such as image 3 A pyrolysis product recovery system using the above-mentioned pyrolysis rotary kiln is shown, including a feeding system connected to the feed port 101 of the pyrolysis rotary kiln 1, and a flue gas exhaust pipe 123 connected to the pyrolysis rotary kiln 1. Gas treatment system, the charcoal unloading system connected to the charcoal unloading port 120 of the pyrolysis rotary furnace 1, the pyrolysis gas recovery system connected to the pyrolysis gas outlet pipe 115 of the pyrolysis rotary furnace 1; the flue gas treatment system is respectively connected to the feed system and the gas-sealed double-seal assembly 103 of the pyrolysis rotary furnace 1; the gas cabinet 23 in the pyrolysis gas recovery system communicates with the burner 119 of the pyrolysis rotary furnace 1.

[0035] The feeding system includes a feeder 5 connected to the feed port 101 of the pyrolysis rotary furnace 1 through the preheating drier 6, and a feeding device is also provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com