TN (twisted nematic) type liquid crystal display panel, TN type liquid crystal display panel preparation method and liquid crystal display device

A liquid crystal panel, one-sided technology, applied in the direction of nonlinear optics, instruments, optics, etc., can solve the difficult problem of realizing narrow frame design of TN-type liquid crystal display panel, and achieve the effect of realizing narrow frame design and reducing frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

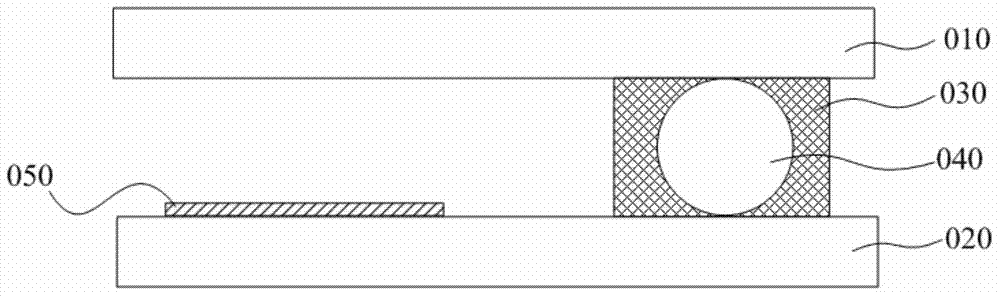

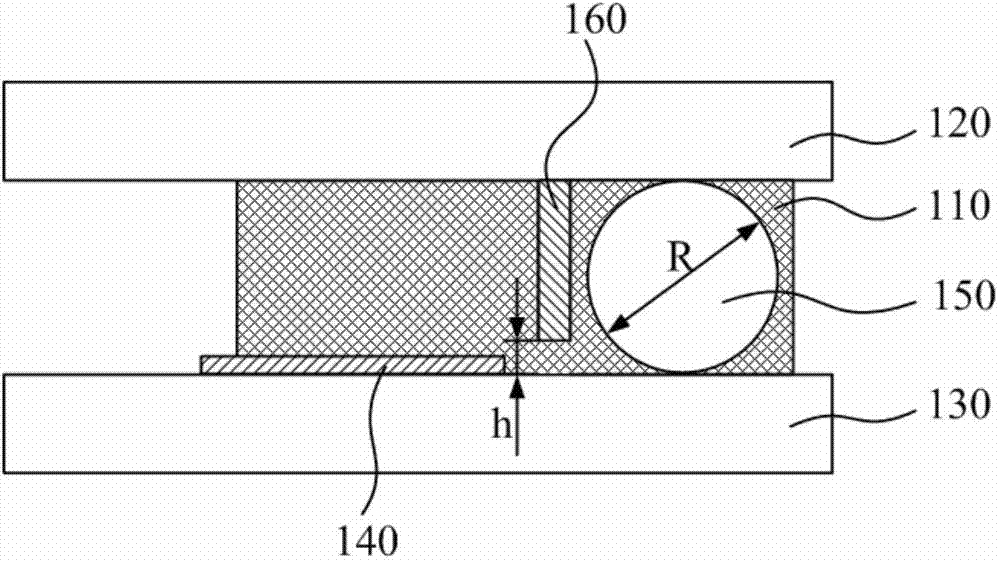

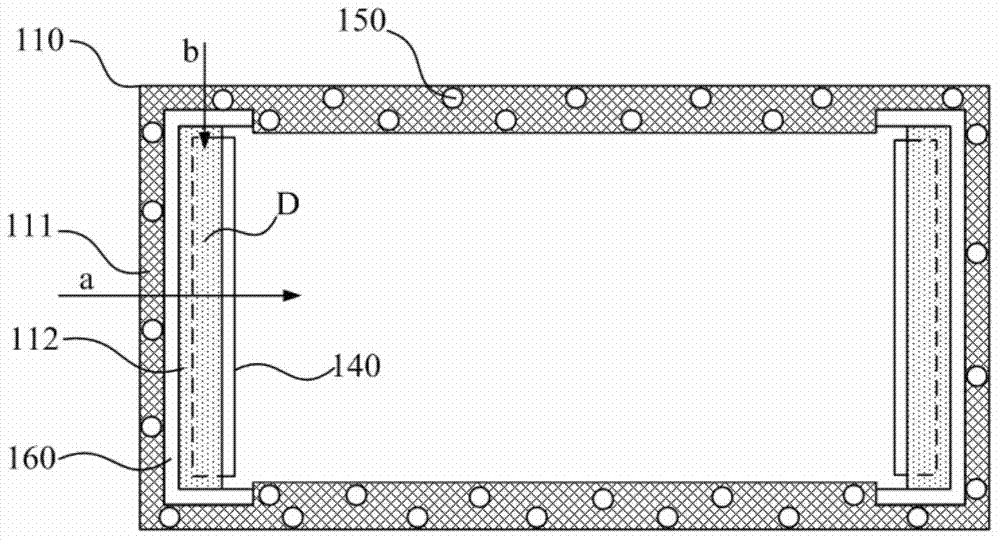

[0038] Please refer to figure 2, the first embodiment provides a TN-type liquid crystal panel, including: an upper substrate 120 and a lower substrate 130 connected to the box through a sealant 110, and the side of the upper substrate 120 facing the lower substrate 130 has a pixel electrode (not shown in the figure out), the side of the lower substrate 130 facing the upper substrate 120 has a common electrode (not shown in the figure) and a gate shift register 140; the sealant 110 includes gold balls 150 doped with conductive pixel electrodes and common electrodes The main sealant 111, and the secondary sealant 112 not doped with gold balls; the side of the upper substrate 120 facing the lower substrate 130 is provided with a retaining wall 160, and the retaining wall 160 is located between the main sealant 111 and the secondary sealant 112 and separates the gate shift register 140 from the primary sealant 111 , the secondary sealant 112 and the gate shift register 140 also h...

Embodiment 2

[0051] On the basis of the TN-type liquid crystal panel provided in the first embodiment above, the second embodiment provides a liquid crystal display device, which has the TN-type liquid crystal panel provided in the first embodiment above.

[0052] In the TN-type liquid crystal panel provided by the above solution, when the coating width of the sealant is constant, along the width direction of the sealant, there will be a certain overlapping area between the secondary sealant and the gate shift register. , so that the frame width of the entire liquid crystal panel can be set smaller, therefore, in the liquid crystal display device provided by the present invention with the above-mentioned TN type liquid crystal panel, the frame of the liquid crystal display device can also be made very small, so as to facilitate the realization of liquid crystal display. Narrow bezel design for display devices.

Embodiment 3

[0054] exist Figure 4 based on the reference Figure 5a ~ Figure 5e , this embodiment also provides a method for preparing the TN-type liquid crystal panel provided in Embodiment 1, including:

[0055] Step 401, such as Figure 5a As shown, the barrier wall 160 is prepared on the pixel electrode of the upper substrate 120; Figure 5b As shown, a gate shift register 140 is prepared on the common electrode of the lower substrate 130;

[0056] Step 402, such as Figure 5c As shown, in the coated area of the upper substrate 120, the part located inside the retaining wall 160 is coated with the secondary sealant 112 of the undoped gold ball 150; Figure 5d As shown, the main sealant 111 doped with gold balls 150 is coated in other parts of the coating area;

[0057] Step 403, such as Figure 5e As shown, the upper substrate 120 and the lower substrate 130 are connected to the box; wherein, after the box is boxed, the barrier wall 160 separates the gate shift register 140 f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com