Polylactic acid grafted quaternized chitosan material and its stereocomposite crystalline nanofiber membrane and their preparation method and application

A technology of quaternized chitosan and composite nanofibers, which is applied in the fields of fiber chemical characteristics, conjugated synthetic polymer artificial filaments, and pharmaceutical formulations, and can solve problems such as the need to improve the crystallinity of stereocomplexes and the degradation of polylactic acid. , achieve broad biomedical application prospects, avoid degradation, and have strong dispersion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

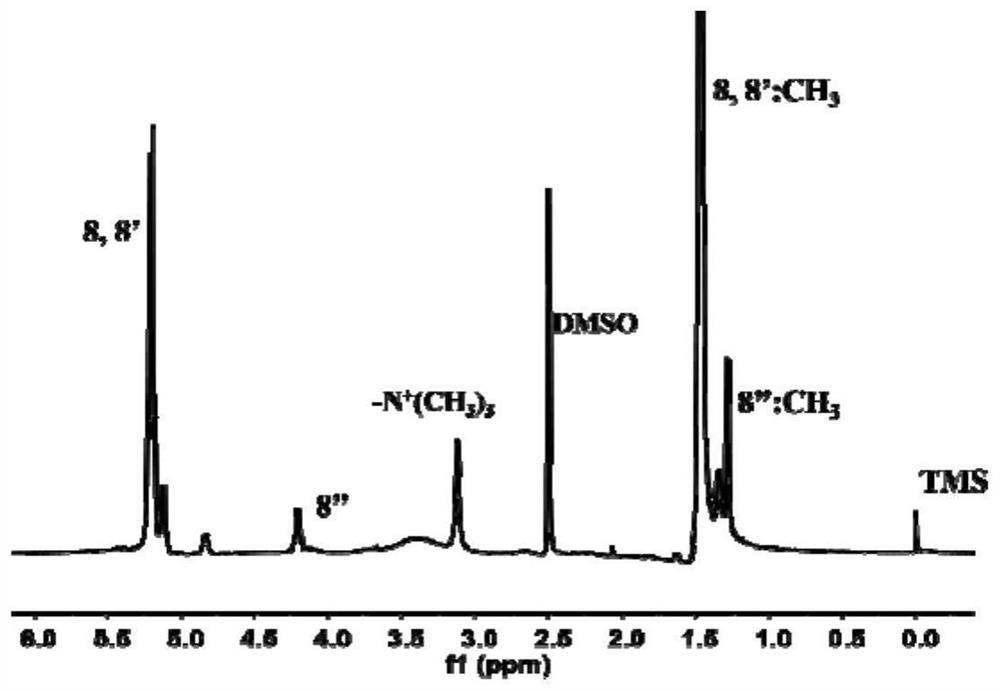

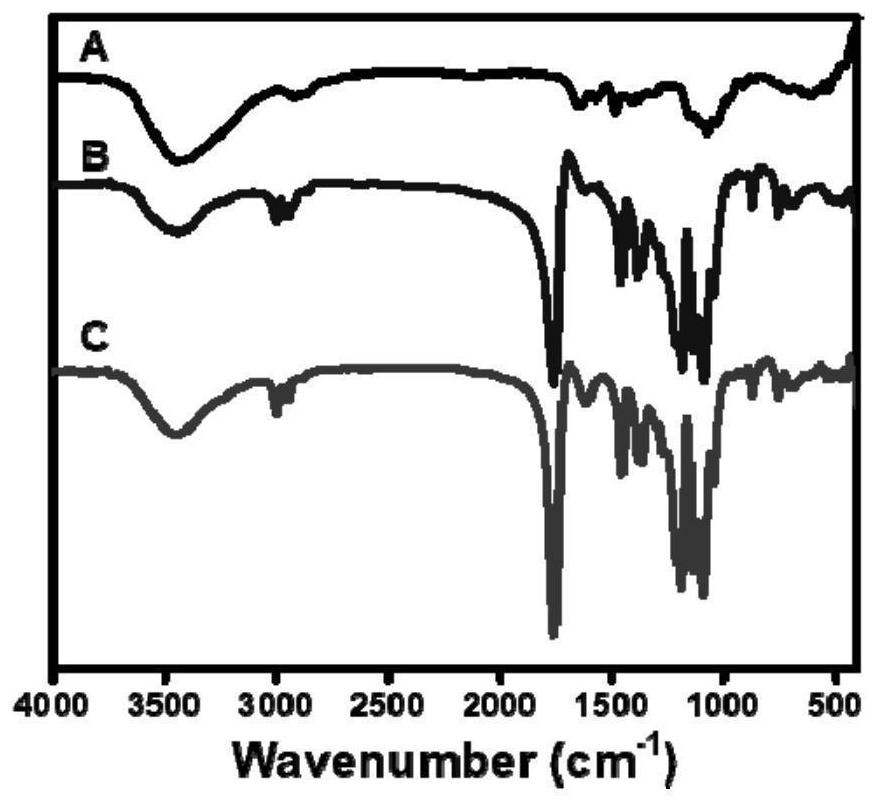

[0049] (1) Preparation of QCS-PLLA

[0050] Under nitrogen protection, the QCS powder prepared and purified by the prior art and L-lactide were added to sulfuric acid in a molar ratio of 1:12 to prepare an acid solution with a solid content of 8% (w / v). The reaction was stirred for 2 h. After the reaction, the reaction solution was poured into a buffer solution composed of 10M sodium hydroxide and 0.2M dipotassium hydrogen phosphate in a pre-ice bath with a mixing ratio of 1:4. After the product was precipitated, it was filtered and purified with water. After thorough washing, the QCS-PLLA was obtained by freeze-drying.

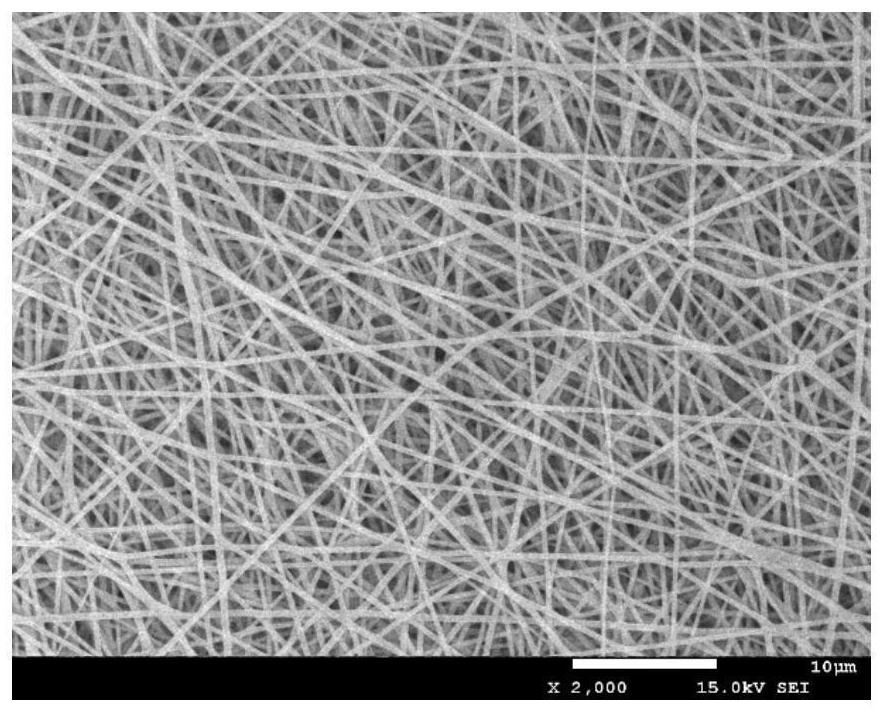

[0051] (2) Preparation of stereocomposite crystalline nanofiber membranes

[0052] D-polylactic acid (weight average molecular weight 100KDa, optical purity 98%), QCS-PLLA and QCS were mixed in a mass ratio of 50:40:10, in hexafluoroisopropanol and dichloromethane (4:1, v / v) to dissolve in, prepare a solution with a solid content of 8% (w / v) concentration,...

Embodiment 2

[0054] (1) Preparation of QCS-PDLA

[0055] Under nitrogen protection, the QCS powder prepared and purified by the prior art and D-lactide were added together in sulfuric acid according to a molar ratio of 1:36 to prepare an acid solution with a solid content of 15% (w / v). The reaction was stirred at ℃ for 6 h. After the reaction was completed, the reaction solution was poured into a buffer solution consisting of 10M sodium hydroxide and 0.2M dipotassium hydrogen phosphate mixed in a ratio of 1:4 in an ice bath. After thorough washing with water, the QCS-PDLA was obtained by freeze-drying.

[0056] (2) Preparation of stereocomposite crystalline nanofiber membranes

[0057] L-polylactic acid (weight average molecular weight 250KDa, optical purity 98%), QCS-PDLA and QCS were mixed in a mass ratio of 70:20:10, in hexafluoroisopropanol and dichloromethane (5:1, v / v ), dissolved in 10% (w / v) concentration of solid content, then added lithium bromide whose total mass was 0.5% and ...

Embodiment 3

[0059] (1) Preparation of QCS-PDLA

[0060] Under nitrogen protection, the QCS powder prepared and purified by the prior art and D-lactide are added together in methanesulfonic acid according to a molar ratio of 1:36 to prepare an acid solution with a solid content of 10% (w / v), The reaction was stirred at 55°C for 6 hours. After the reaction was completed, the reaction solution was poured into a buffer solution consisting of 10M sodium hydroxide and 0.2M dipotassium hydrogen phosphate in a pre-ice bath with a mixing ratio of 1:4. After the product was precipitated, it was filtered. The QCS-PLLA was obtained by washing with pure water and freeze-drying.

[0061] (2) Preparation of stereocomposite crystalline nanofiber membranes

[0062] L-polylactic acid (weight average molecular weight 200KDa, optical purity 98%), QCS-PDLA and QCS were mixed in a mass ratio of 60:30:10 in hexafluoroisopropanol and THF (1:1, v / v) Dissolve, prepare a solution with a solid content of 14% (w / v)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com