Furnace tube modular mechanism suitable for PECVD equipment

A modular, furnace tube technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of time-consuming and laborious equipment maintenance, troublesome furnace tubes, etc., achieve simple structure, improve work efficiency, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

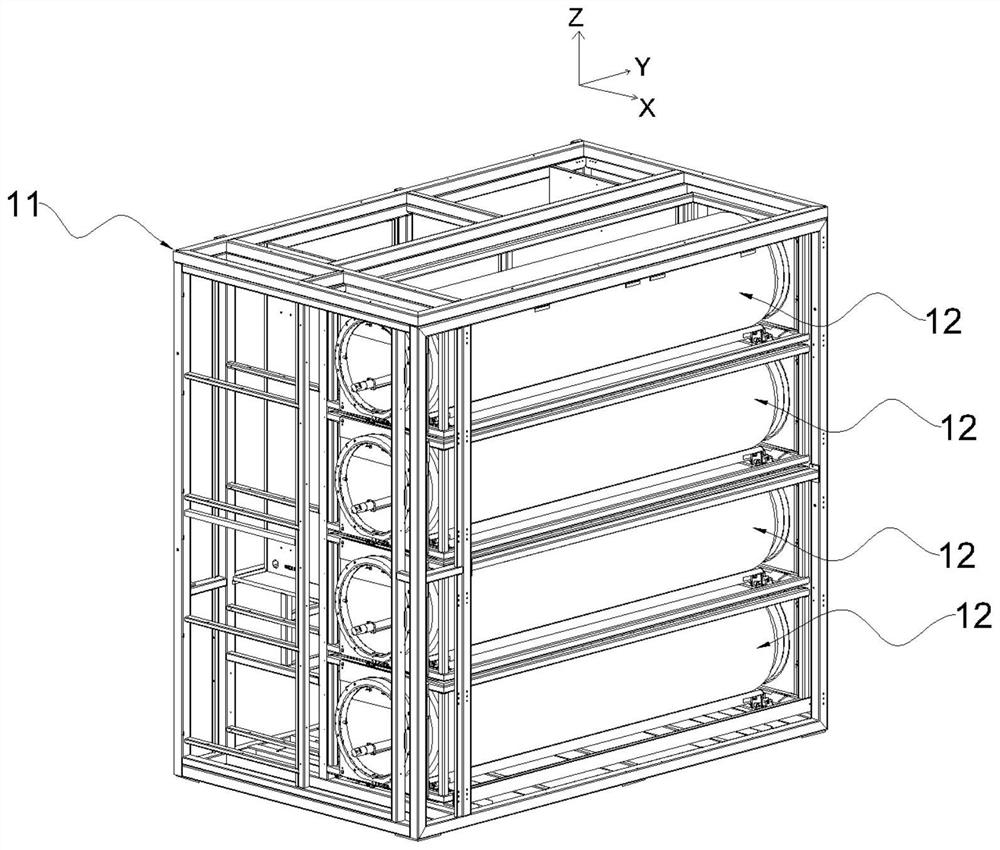

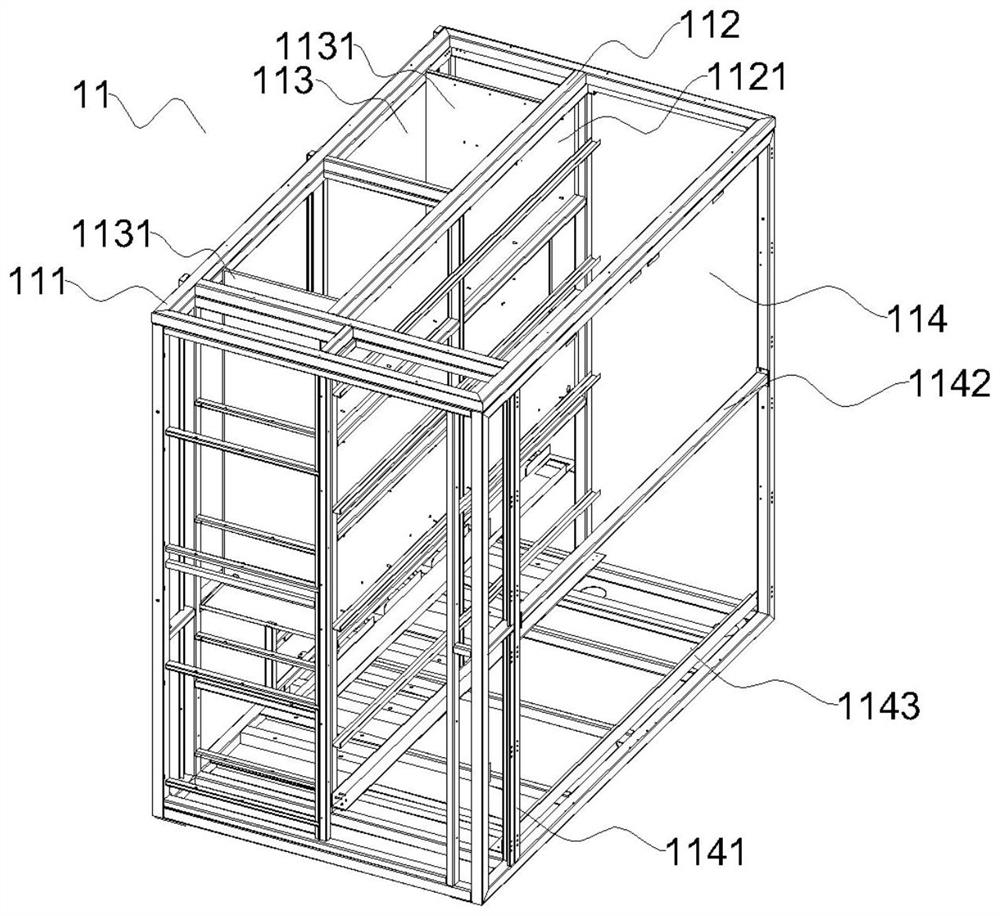

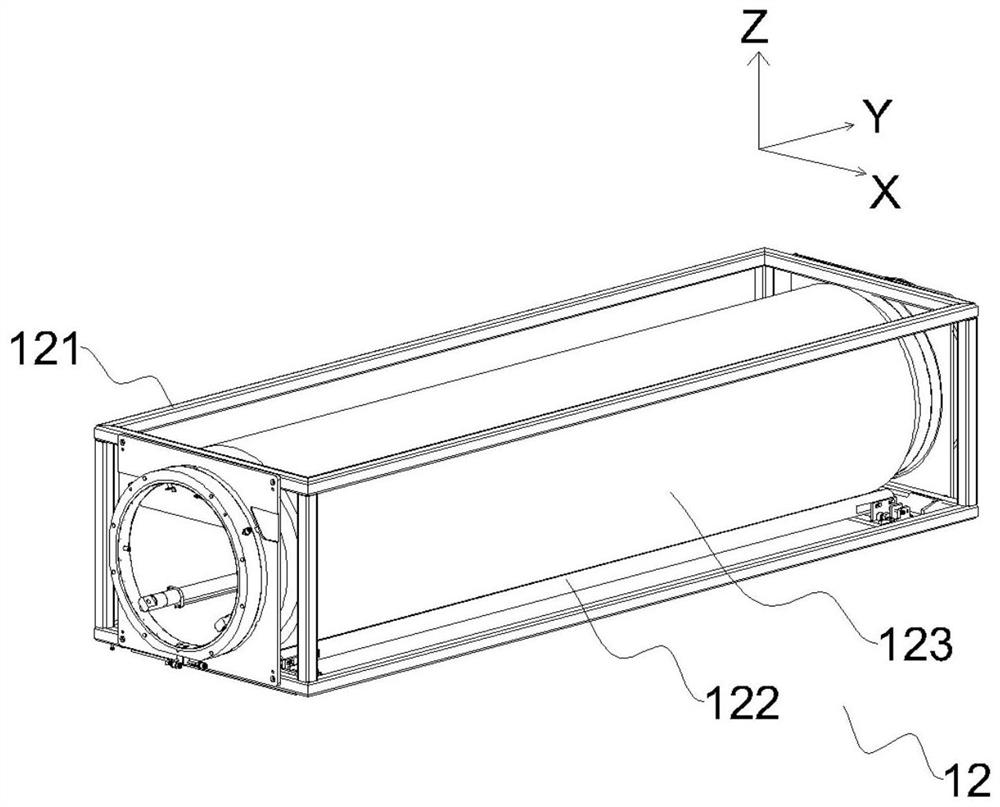

[0033] According to one embodiment of the present invention, combining Figure 1~2 , the present invention provides a furnace tube modular mechanism suitable for PECVD equipment, which includes: a hollow single-sided open frame 11; and at least one set of Furnace assembly 12;

[0034] Wherein, the single-sided open frame 11 comprises: an integral fixed frame 111; The water pipe placement chamber 113 and the furnace body placement chamber 114 are provided with openings for taking and placing the furnace body assembly 12 at the side end of the furnace body placement chamber 114 .

[0035] further, combine figure 2 The side end of the furnace body placement chamber 114 is open and detachably provided with movable vertical beams 1141 and movable cross beams 1142 to prevent the furnace body assembly 12 from slipping out of the furnace body placement chamber 114 accidentally. A sliding device 1143 for adjusting the position of the furnace body assembly 12 is provided at the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com