Double-drill-bit swing arm type breaking hammer

A technology of breaking hammer and drill bit, applied in impact drilling, reciprocating drilling rig, drilling equipment and methods, etc., can solve the problems of low crushing effect and crushing efficiency, and achieve the effect of improving crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

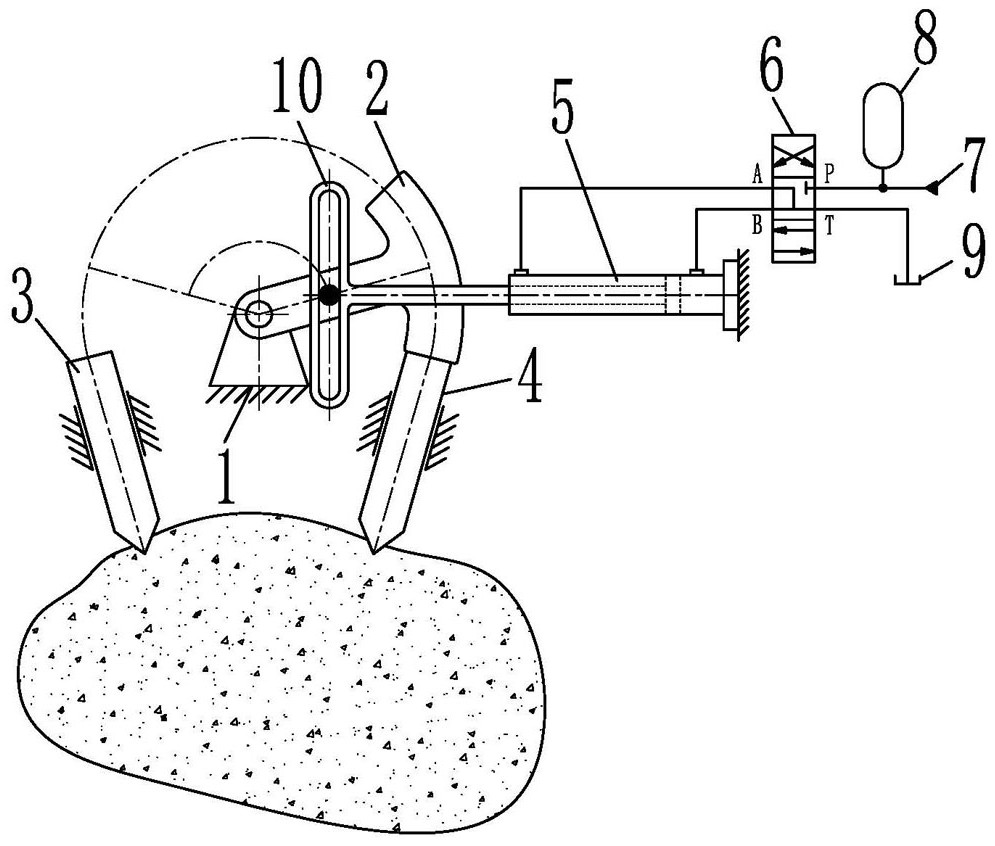

[0017] Such as figure 1 As shown, a double-drilling arm-type breaker includes a base 1, a reciprocating hammer 2, a drill bit 3, a drill bit 2 4, an oil cylinder 5, a reversing valve 6, a pump source 7, an accumulator 8, The oil tank 9, the reciprocating hammer 2 is hinged on the base 1, the drill bit 3 and the drill bit 2 4 are respectively installed on the base 1, the drill bit 3 and the drill bit 2 4 are drill bits for breaking rocks with the same structure , Drill bit 1 3 and drill bit 2 4 form an included angle, the included angle is 15︒~30︒, the setting of the included angle can realize centralized crushing at the same point. The tail of the oil cylinder 5 is fixedly installed on the base 1, and a linkage device is provided between the oil cylinder 5 and the reciprocating hammer 2. The linkage device is that the movable rod of the oil cylinder 5 drives the straight grooved rod 10 provided at the front end of the movable rod to move, driving the reciprocating hammer 2. T...

Embodiment 2

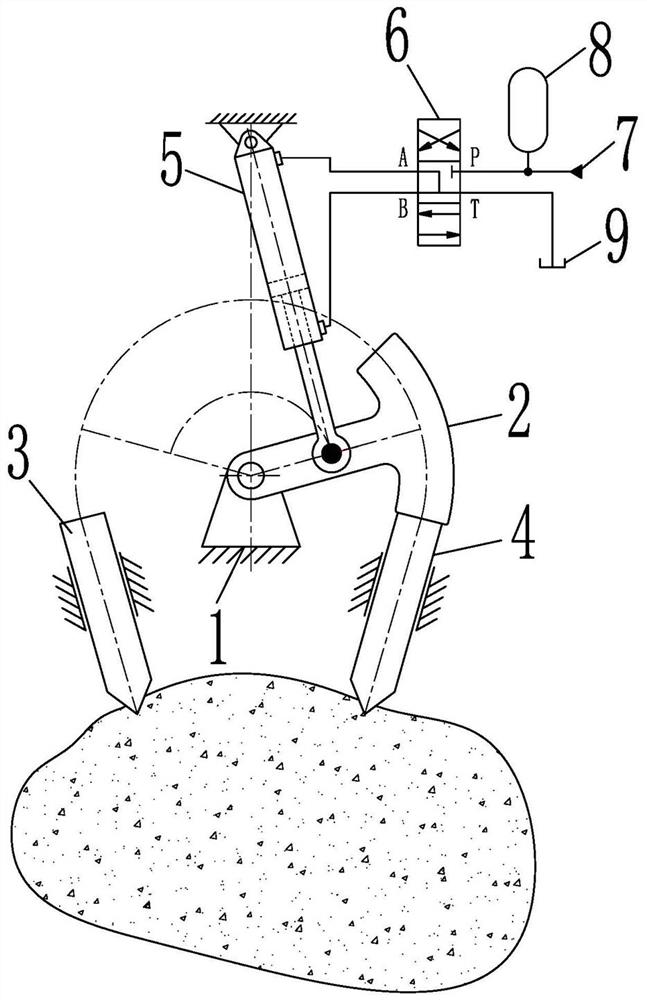

[0023] On the basis of embodiment 1, embodiment 2 changes the linkage device. In Embodiment 2, the tail of the oil cylinder 5 is hinged on the base 1, and the front end of the movable rod of the oil cylinder 5 is hinged with the round rod provided on the cantilever of the reciprocating hammer 2. The movable rod of the oil cylinder 5 drives the straight grooved rod 10 arranged at the front end of the movable rod to move, and the straight grooved rod 10 is hinged with the round rod provided on the cantilever of the reciprocating hammer 2, thereby driving the reciprocating hammer 2 to reciprocate and rotate to hit the drill bit 1 3 and the drill bit 2 4 .

[0024] The working principle of embodiment 2 is as follows:

[0025] The reversing valve 6 is switched to the upper position, the high-pressure oil from the pump source 7 enters the rod cavity of the oil cylinder 5, and the movable rod of the oil cylinder 5 is pushed to retract. 2 Rotate counterclockwise; when the reciprocat...

Embodiment 3

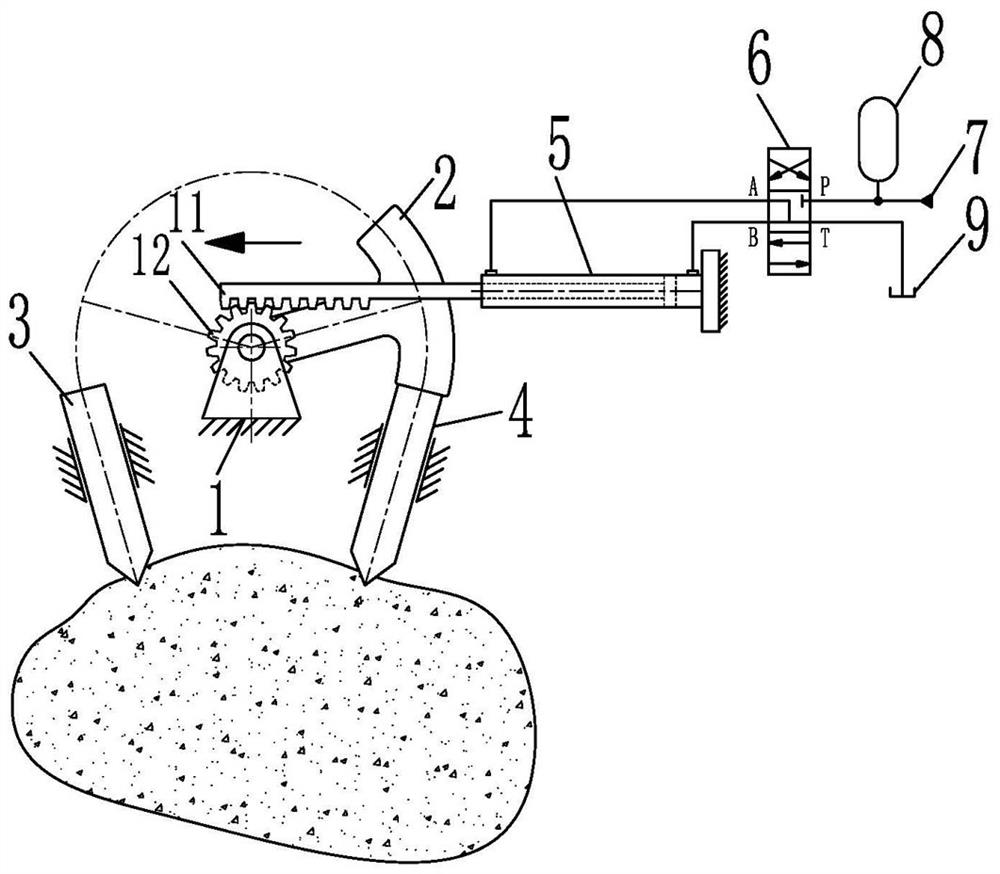

[0027] On the basis of embodiment 1, embodiment 3 changes the linkage device. In Embodiment 3, a rack 11 is provided at the front end of the movable rod of the oil cylinder 5 , and a gear 12 is provided at the hinge joint between the reciprocating hammer 2 and the base 1 , and the rack 11 and the gear 12 are engaged and connected. The movable rod of the oil cylinder 5 drives the rack 11 provided at the front end of the movable rod to move, the rack 11 moves to drive the gear 12 to rotate, and the gear 12 is relatively fixed to the reciprocating hammer 2, thereby driving the reciprocating hammer 2 to reciprocate and hit the drill bit 1 3 and the drill bit 2 4.

[0028] The working principle of embodiment 3 is as follows:

[0029] The reversing valve 6 is switched to the upper position, the high-pressure oil from the pump source 7 enters the rodless cavity of the oil cylinder 5, and the movable rod of the oil cylinder 5 is pushed out, the rack 11 provided at the front end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com