Power centralized wind power generation system

A wind power generation system, centralized technology, applied in wind power generation, wind power generators, wind power generators consistent with the wind direction, etc., can solve problems such as instability, low power generation power and quality, large volume, etc., and achieve a reasonable internal structure design , The output power is more stable and the effect of high output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

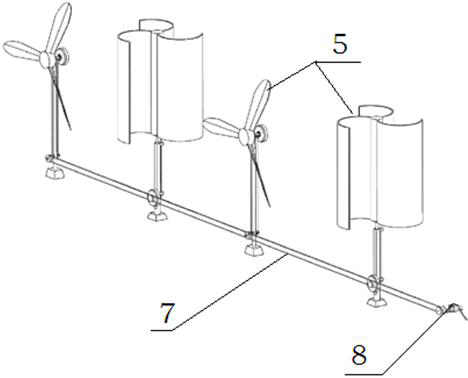

[0033] Such as figure 1 As shown, a power centralized wind power generation system includes a number of wind power collection devices, each wind power collection device converts collected wind energy into kinetic energy, and the power is concentrated through a common connector to drive the generator to generate electricity; the wind power collection device Including wind blades 5, one-way transmission components, transmission gear sets, power output components, wind blades 5 collect wind energy, which is transmitted from the one-way transmission components and transmission gear sets to the power output components, and the power output components are driven by a stable one-way power Output to the connecting piece, which is connected to the generator 8.

[0034] The wind blade is a vertical axis wind blade or a horizontal axis wind blade, and the wind collecting device is divided into a horizontal axis power collecting device or / and a vertical axis power collecting device.

[0035] T...

Embodiment 2

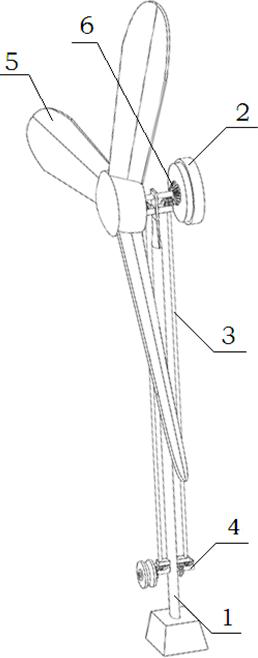

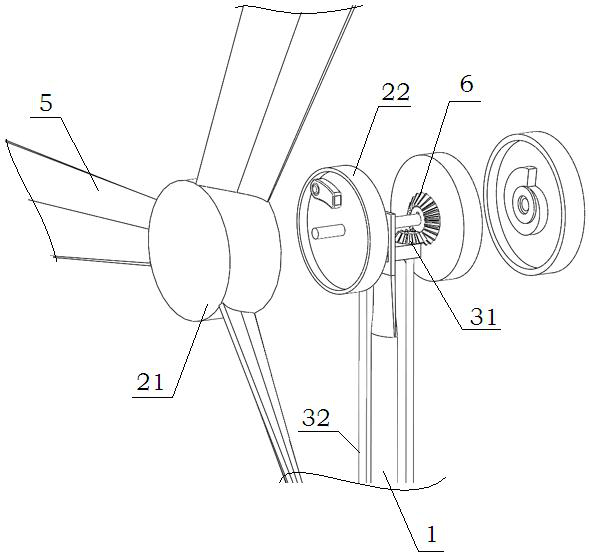

[0038] As a specific structural design of Example 1, such as figure 2 , 3 4, the horizontal shaft power collection device includes a horizontal shaft device bracket 1, a one-way transmission assembly 2, a transmission gear set 3, and a horizontal power output assembly 4 mounted on the horizontal shaft device bracket 1. The transmission assembly 2 includes two transmission discs 21 on the outer side and two one-way turntables 22 on the inside. One of the transmission discs 21 is equipped with a wind blade 5, and the transmission disc 21 is sleeved on the one-way turntable 22. On the upper side, a ratchet is installed in the transmission disc 21, a pawl matched with the ratchet is installed in the one-way turntable 22, and the installation directions of the ratchets and pawls in the two transmission discs 21 and the one-way turntable 22 are opposite, through the ratchet and pawl Form a one-way transmission.

[0039] The wind blades rotate around a horizontal axis. The one-way tran...

Embodiment 3

[0044] As a specific structural design of Example 1, such as Figure 5 , 6 As shown in 7, the vertical axis wind collecting device includes wind blades 5 mounted on the vertical axis, a first gear 10 mounted on the vertical axis, a second gear 11 meshing with the first gear 10, and a second gear 11 is installed on the upper end of the transmission shaft, and the third gear 12 is installed on the lower end of the transmission shaft for connecting the vertical power output assembly. The vertical axis wind blade rotates around the vertical center. It is made up of multiple curved blades installed symmetrically relative to the vertical center, and the blades have the same turning direction. Therefore, when facing horizontal wind from different directions, the vertical axis wind power rotates in the same direction. All are clockwise or counterclockwise.

[0045] The vertical power output assembly includes a vertical output gear 13 meshing with the third gear 12. The vertical output ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com