Method for pre-judging formaldehyde adsorption quantity in textiles containing adipic acid dihydrazide

An adipic acid dihydrazide and formaldehyde adsorption technology, which is used in measuring devices, instruments, scientific instruments, etc., to reduce economic losses, reduce health hazards, and improve the quality of textiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Take 2 representative samples from the underwear, cut them into pieces and mix them evenly, weigh 1g of the samples, place them in a stoppered conical flask, add 25ml of water, extract them ultrasonically for 70min at an extraction temperature of 70°C, filter and wait for Measurement.

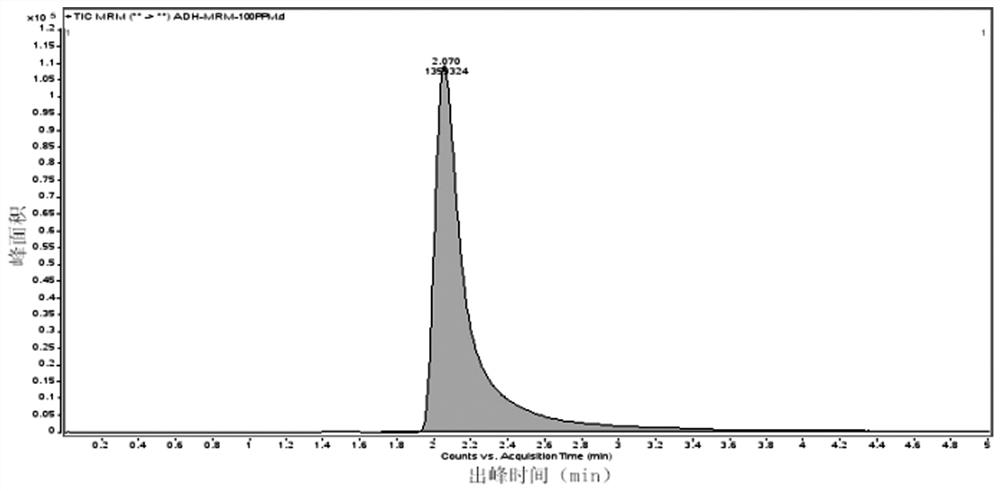

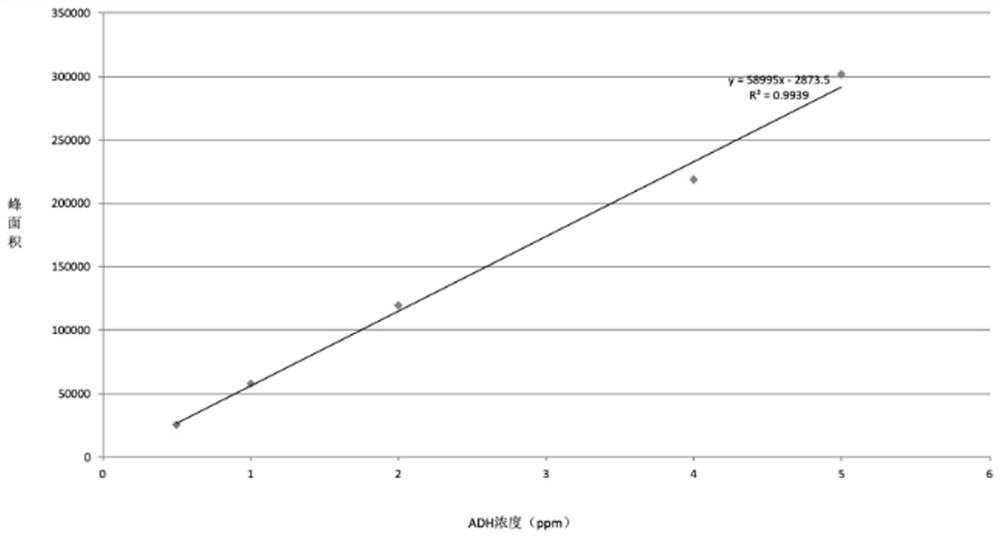

[0031] Configure the ADH standard working curve: configure five concentration points of 0.5ppm, 1ppm, 2ppm, 4ppm, and 5ppm, draw the ADH standard working curve, and analyze it with LC-MS / MS; the conditions of the liquid chromatography-mass spectrometer (LC-MS) are as follows: The chromatographic column is Agilent Proshell120Hilic column, 2.7μm, 3.0mm×100mm, column temperature: 40°C; mobile phase: 0.1% formic acid solution and acetonitrile, the gradient elution program used is shown in Table 2, the flow rate is 0.3mL / min, and the injection volume is 1μL ; Monitoring transition (m / z): 175 / 143 (9eV), 175 / 115 (15eV), 175 / 111 (9eV), quantitative transition (m / z): 175 / 143 (9eV) scan.

[0032]...

Embodiment 2

[0037] Take 2 representative samples from the underwear, cut them into pieces and mix them evenly, weigh 1g of the samples, place them in a stoppered conical flask, add 25ml of water, extract them ultrasonically for 70min at an extraction temperature of 70°C, filter and wait for Measurement.

[0038] Configure ADH standard working curve: configure five concentration points of 0.5ppm, 1ppm, 2ppm, 4ppm, and 5ppm, draw ADH standard working curve, and analyze by LC-MS / MS.

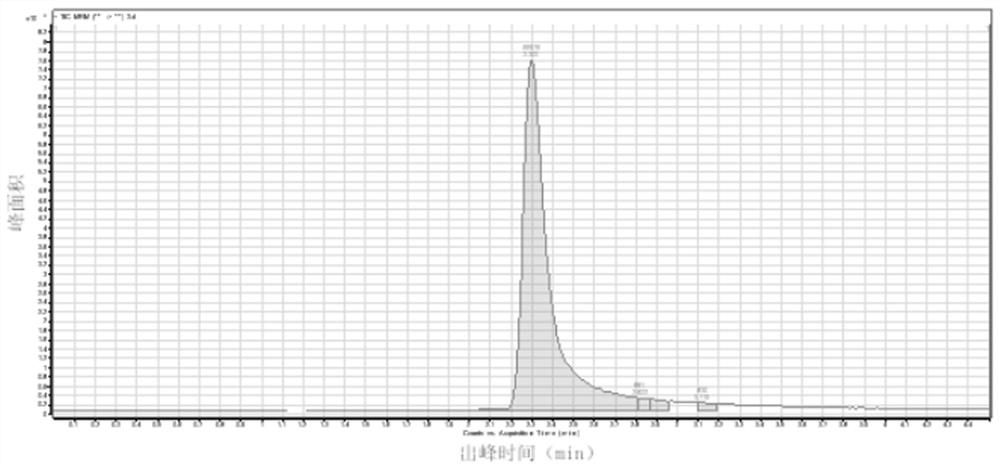

[0039] Liquid chromatography-mass spectrometer (LC-MS) conditions are as follows: chromatographic column is AgilentProshell120Hilic post, 2.7 μm, 3.0mm×100mm, column temperature: 40 ℃; Mobile phase: 0.1% formic acid solution and acetonitrile, the gradient elution program that adopts See Table 1, flow rate 0.3mL / min, injection volume 1μL; monitoring ion pair (m / z): 175 / 143 (9eV), 175 / 115 (15eV), 175 / 111 (9eV), quantitative ion pair (m / z): 175 / 143 (9eV) scan.

[0040] The liquid chromatography-mass spectrogram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com