Rapid suspension type photovoltaic power generation assembly with dynamic linkage adjustment

A photovoltaic power generation and hanging technology, applied in photovoltaic power generation, photovoltaic modules, electrical components, etc., can solve the problems of troublesome loading and unloading of photovoltaic panels, photovoltaic panels blocking sunlight, troublesome disassembly and maintenance, etc., to reduce shading rate and facilitate shading , reduce the effect of shading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

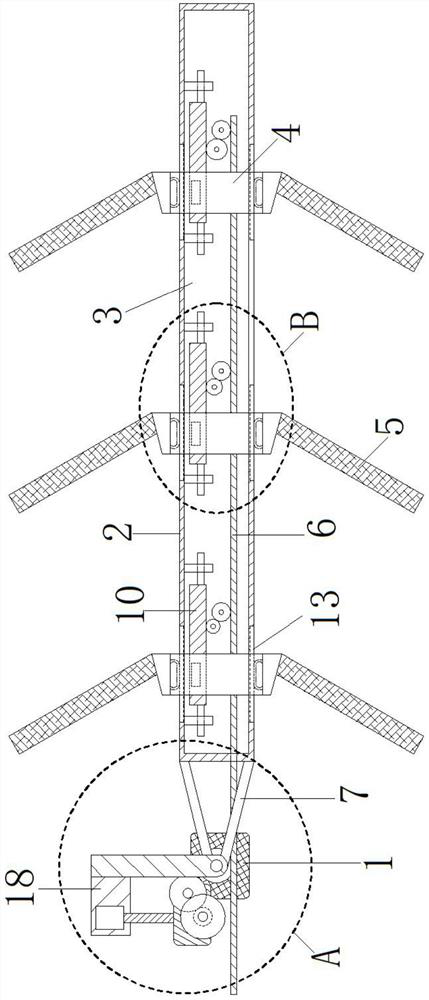

[0029] see figure 1 , figure 2 One side of the first power unit 1 is connected with a second fixed support body 2, and a plurality of third suspension bodies 4 are installed on the second fixed support body 2, and the two sides of the third suspension body 4 are connected with obliquely arranged photovoltaic The power generation board 5 and the upper side panel of the second fixed support body 2 are provided with a second installation groove 3 , and the second fixed support body 2 is equipped with a rack plate 6 that passes through the second installation groove 3 longitudinally.

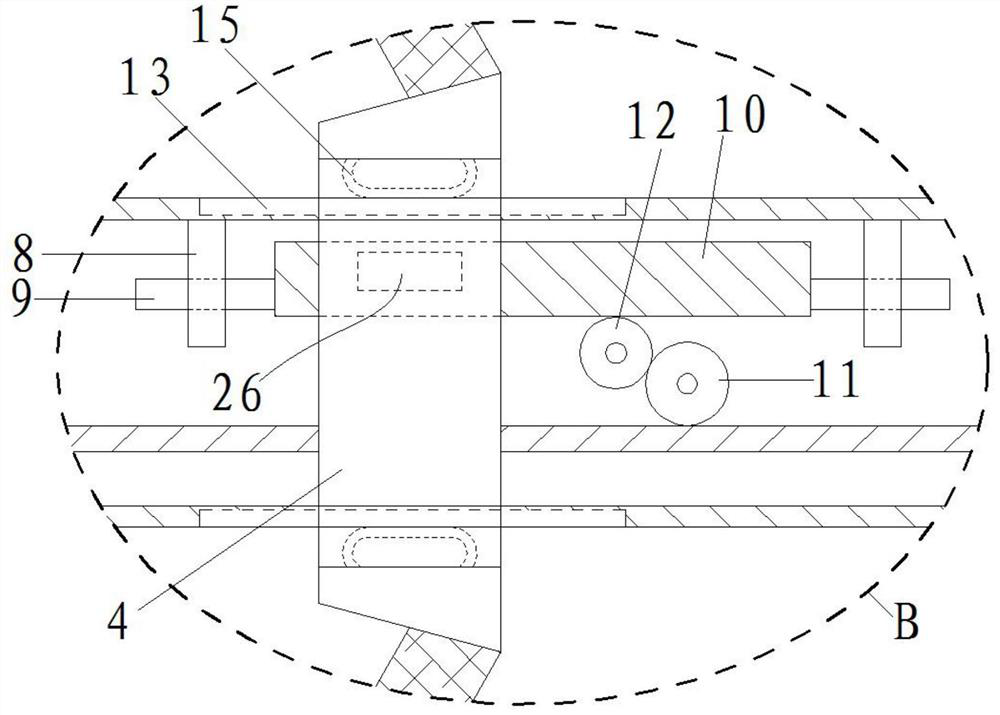

[0030] see figure 2 , Figure 4 , the second installation groove body 3 of the second fixed support body 2 is fixedly provided with several groups of third guiding and fixing plates 8, and a third synchronous rack 10 is movably installed between each group of third guiding and fixing plates 8, and the second The second installation groove body 3 of the fixed support body 2 is fixedly provided w...

Embodiment 2

[0034] In the present invention:

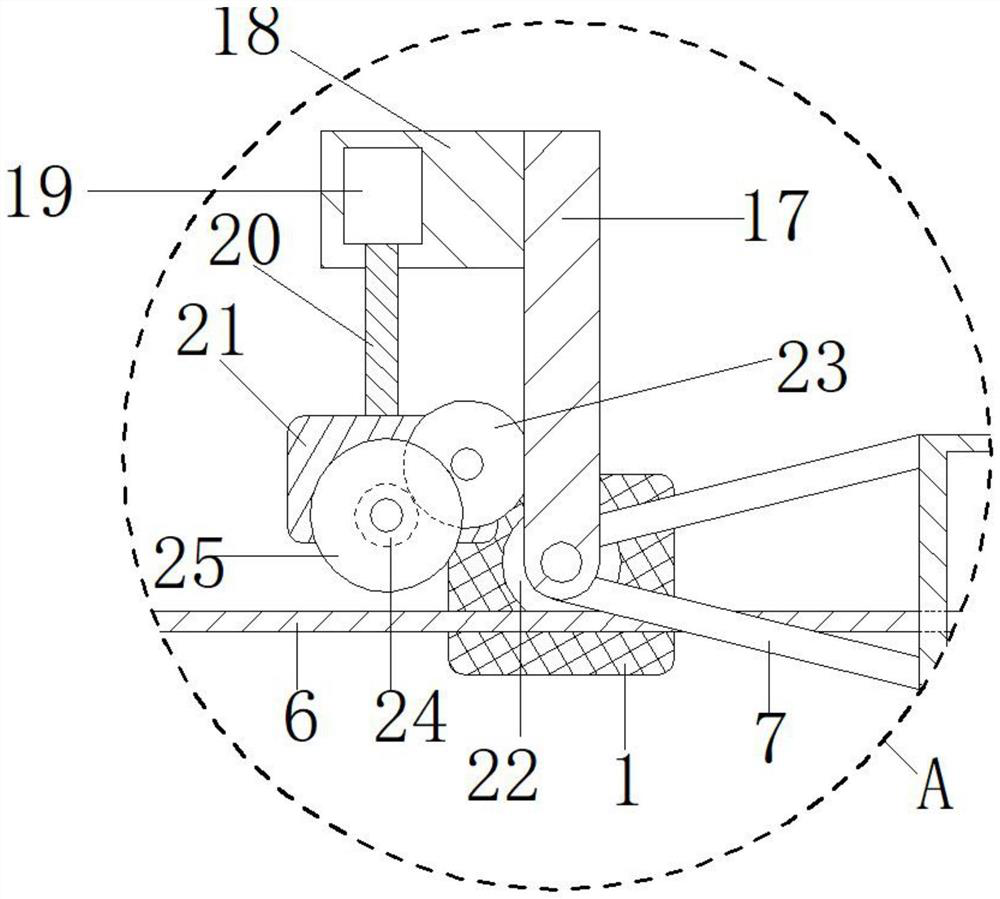

[0035] The output shaft on the first power unit 1: there are the main shaft drive gear 22, one end of the first rotating bracket 7, and one end of the fourth fixed connecting plate 17 arranged sequentially from bottom to top.

[0036] The fourth telescopic driving device 19: used to drive the corresponding gear assembly to advance the penetrating rack plate 6, and the other is used to drive the corresponding gear assembly to advance and retreat the penetrating rack plate 6, and adjust the distance between each third suspension body 3 adjust.

[0037] Several second drive gears in the groove 12 gear radii that are arranged on the second fixed support body 2 are different (increase gradually), when passing through the rack plate 6 to advance and retreat, because the gear of the drive gear 11 in the first groove is Similarly, the greater the radius of the driving gear 12 in the second groove, the greater the regulation of the third synchronous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com