Straw returning method and straw returning comprehensive land preparation machine

A soil preparation machine and straw technology, which is applied in the field of farming technology and equipment, can solve the problem that straw cannot be handled, and achieve the effects of excellent soil moisture conservation, simple structure, and improved drought resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

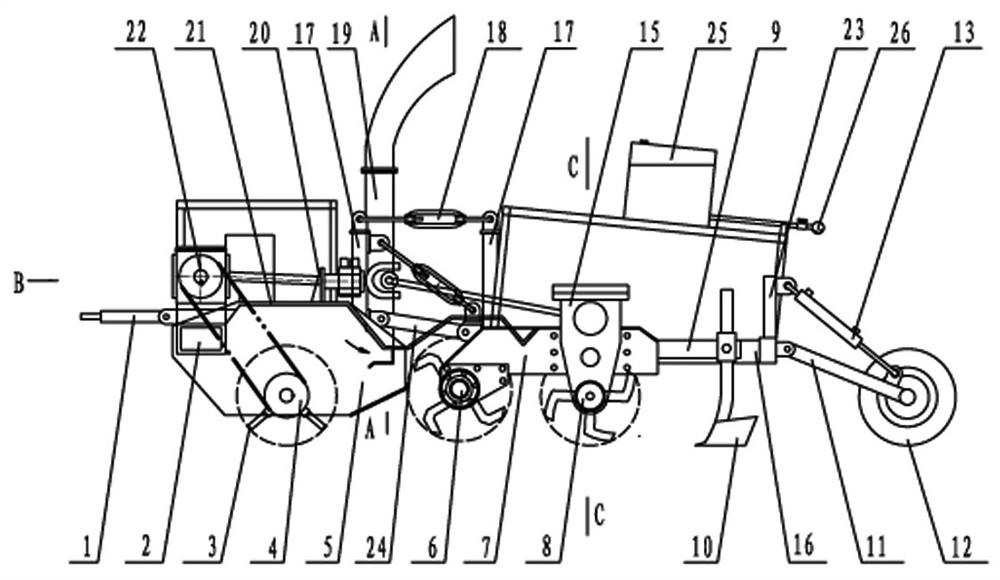

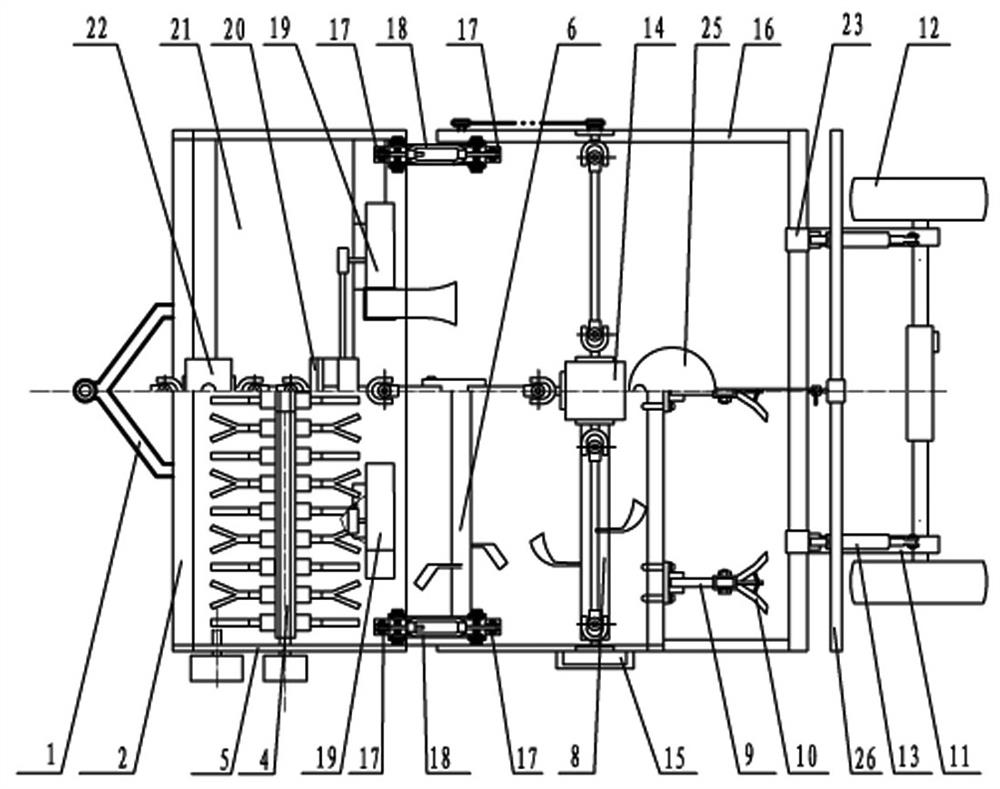

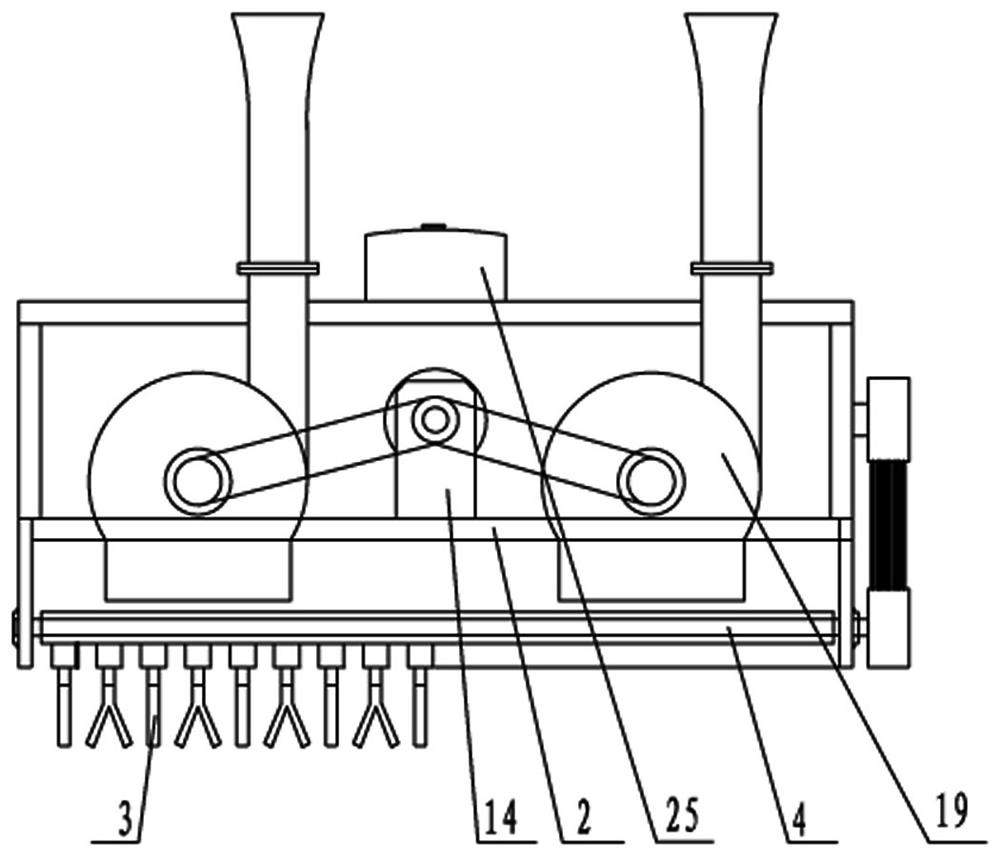

[0037] As shown in the figure, a comprehensive soil preparation machine for straw returning to the field of the present invention includes: a front frame, a middle frame and a rear frame. , rear beam and two front frame side plates 5, a traction frame is arranged at the front part of the front frame, a main gearbox 22 is arranged at the top, a blower fan 19 and a transmission system 20 are arranged at the rear, crushing rollers 4 are arranged at the bottom, and crushing knives are arranged on the crushing rollers 3. The middle frame is the part for stubble removal, rotary tillage, ridge raising, and liquid dripping. The middle frame 16 includes: a front beam, a rear beam and two side plates 7 of the middle frame, and a sub-gearbox 14 is arranged on the upper part of the middle frame. , bacteria liquid tank 25 and drip tube 26, the stubble removal roller 6 is arranged at the lower front end of the middle frame, the rotary tillage roller 8 is arranged at the middle part, the ridg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com