One-time implantation type composite dental implant

A dental implant, an integrated technology, applied in dentistry, dental implants, medical science and other directions, can solve the problems of not being able to fit closely, destroying the overall strength, and failing to achieve accuracy, to increase the contact area, prevent bone necrosis, improve The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

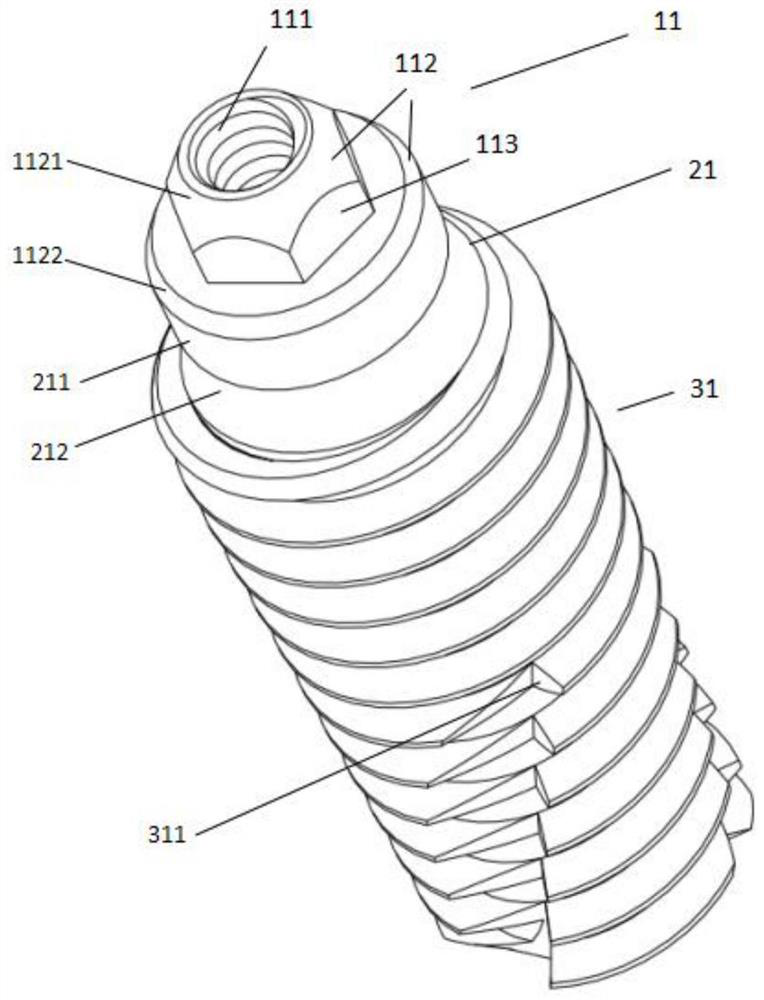

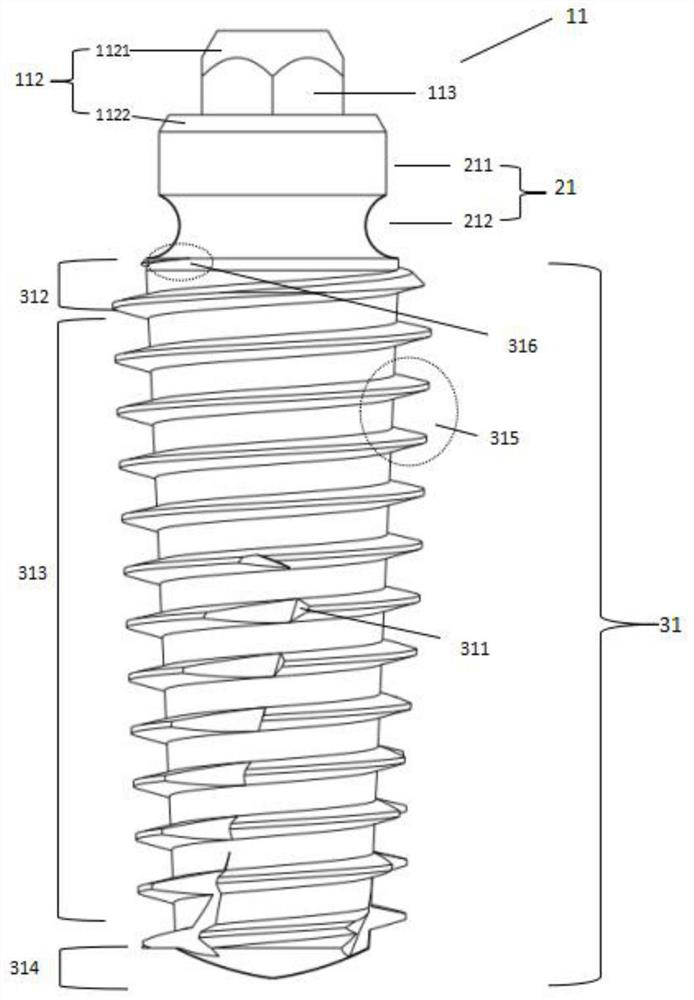

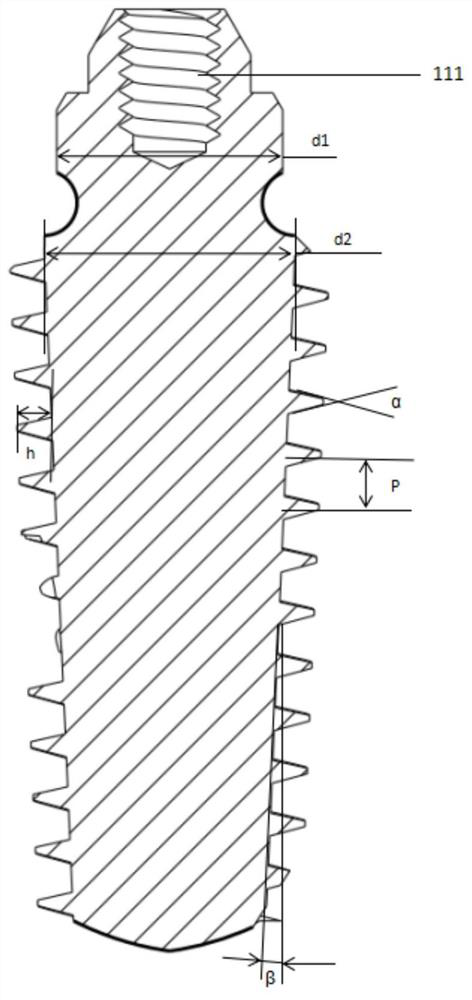

[0033] Embodiment one: by Figure 1 to Figure 3 Given, a one-time implantable composite dental implant, the composite dental implant includes an integrated retention structure 11, a gingival segment 21 and a helical retainer 31 from top to bottom, and the retention structure 11 includes a central bolt channel 111. Retention plane 113 and retention outer wall 112. The central bolt channel 111 is a metric coarse thread with thread specifications of M1.4, M1.6, and M1.8. The retention outer wall 112 includes an upper retention outer wall 1121 and a lower retention outer wall 1121. The retaining outer wall 1122, the upper retaining outer wall 1121 and the lower retaining outer wall 1122 are discontinuous slopes under the same taper, which can be seamlessly fitted with the denture structure connected thereto, and the gingival passage 21 includes a gingival platform 211 and a platform transfer section 212, the platform transfer section 212 is a concave arc surface with a radius of 0...

Embodiment 2

[0034] Embodiment 2, on the basis of Embodiment 1, the helical retainer 31 implanted in human tissue sequentially includes a cylindrical section 312, a conical section 313 and a tail cone section 314 from top to bottom, and the cylindrical section 312 is cylindrical with upper and lower diameters, and the height of the cylindrical section is between 0.15 mm and 0.5 mm, which can increase the contact area between the implant and the jaw, and improve the stability of the implant. The tapered section 313 consists of The diameter of the end close to the cylindrical section 312 is reduced to the end close to the tail cone section 314 to form an inverted cone shape. To achieve excellent initial stability even when the bone quality is poor, the tail cone section 314 is an arc-shaped cone whose side is protruding outward, and the outer surfaces of the cylindrical section 312 and the tapered section 313 are arranged There is a continuous helical thread 315 .

[0035] On the basis of t...

Embodiment 3

[0036] Embodiment 3, on the basis of Embodiment 2, the helical thread 315 is provided with a cutting edge 311, and the helical cutting edge 311 is formed by setting a triangular notch on the helical thread, and each of the helical cutting edges is formed in each circle of the helical thread. There are three equidistant arrays around the central axis. The rotation angle of the helical cutting edge 311 is 10°-30° relative to the central axis of the implant, which can adjust the implant direction and has good self-tapping performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Arc radius | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com