Boiler hoisting sling in closed factory area and construction method thereof

A boiler and spreader technology, applied in the field of spreaders, can solve problems such as narrow space and complex working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

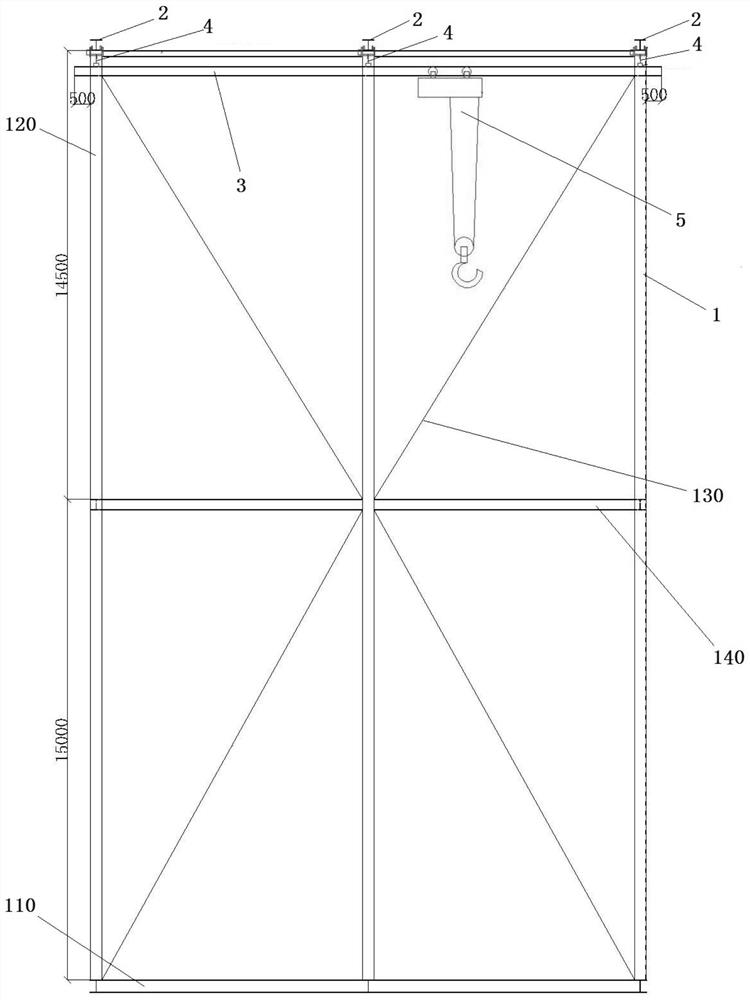

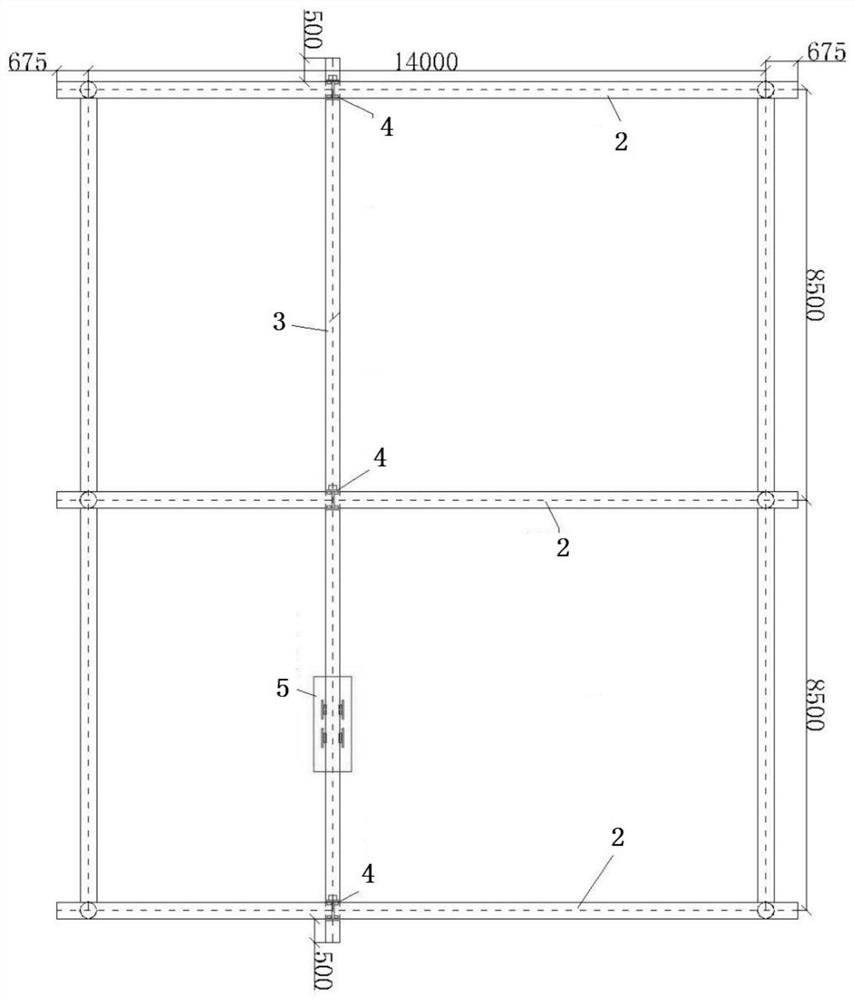

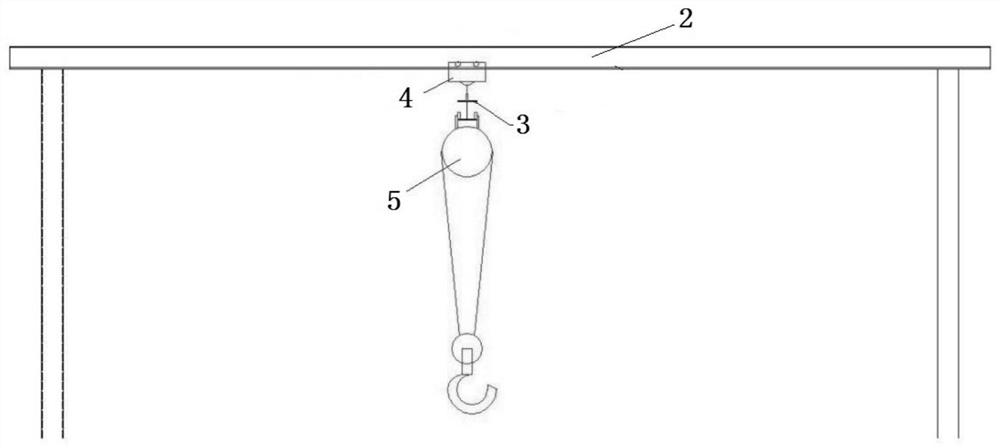

[0031] Such as Figure 1 ~ Figure 3 As shown, a boiler hoisting sling in a closed factory area includes an underframe 1, a fixed track beam 2, a moving track beam 3, a cat head crane 4 and a hoist 5, the underframe 1 is fixed on the ground, and the top of the underframe 1 A plurality of fixed track beams 2 are arranged, and the moving track beam 3 is suspended below the fixed track beam 2 through the cat head crane 4. The moving track beam 3 is equipped with a gourd 5, and the moving direction of the gourd 5 on the moving track beam 3 is the same as that of the cat head. The moving direction of the head crane 4 on the fixed track beam 2 is perpendicular to each other. During the hoisting operation, the hoist 5 moves on the moving track beam 3 and the moving track beam 3 moves on the fixed track beam 2, so as to meet the requirements in the hoisting operation area. Hoisting requirements.

[0032] Due to other reasons, the roof of the factory building cannot be removed, so it i...

Embodiment 2

[0034] Such as Figure 1 ~ Figure 3 As shown, the present embodiment is a further improvement carried out on the basis of embodiment 1, which is specifically as follows:

[0035] The number of fixed track beams 2 set on the underframe 1 is three.

[0036] Furthermore, the number of cat head cranes 4 is three, and the three cat head cranes 4 are respectively installed on the three fixed track beams 2, and the moving track beam 3 is suspended below the three fixed track beams 2 through the three cat head cranes 4 .

[0037] Certainly, the quantity of fixed track beam 2 also can be many, such as four, five, two etc., and the quantity of cat head crane 4 is then at least two, preferably the quantity of cat head crane 4 and the quantity of fixed track beam 2 equal.

Embodiment 3

[0039] Such as Figure 1 ~ Figure 3 As shown, the present embodiment is a further improvement carried out on the basis of embodiment 1 or 2, which is specifically as follows:

[0040] The fixed track beam 2 adopts HW440*300*11*18 I-beam, and the material is Q235; the moving track beam 3 adopts I45A I-beam; the cat head crane 4 adopts 10T cat head crane 4; the hoist 5 adopts 10T electric hoist, using 10T Electric hoist, electric hoist load 10T, considering factors such as electric hoist self-weight and lifting acceleration, the load of electric hoist on moving track beam 3 is G = 13T = 130KN; it can effectively meet the hoisting requirements, specifically meet the requirements of shear resistance, bending resistance, resistance Pull, maximum load and other hoisting requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com