A method for reducing the odor of pneumatic tires and low-odor tires

A pneumatic tire and odor technology, applied in the field of pneumatic tires, can solve the problems of unfavorable promotion and application and high cost, and achieve the effects of facilitating promotion, reducing odor level and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] According to the components and their proportions shown in Table 1, put rubber, carbon black, oil, etc. into the Banbury internal mixer in sequence, and unload after banburying at 135°C for 120 seconds to obtain a master batch; the master batch The rubber and sulfur were mixed in a Banbury internal mixer at 105°C for 90 seconds and then unloaded to obtain a rubber composition.

[0046] The specific components of the rubber composition in Table 1 embodiment 1-3 (unit: parts by weight)

[0047] components Example 1 Example 2 Example 3 natural rubber 0 20 40 Butyl rubber 100 80 60 carbon black 50 50 50 naphthenic oil 7 7 7 Zinc oxide 3 3 3 stearic acid 1 1 1 Adhesive resin 3 3 3 Dispersant 3 3 3 sulfur 1.5 1.5 1.5

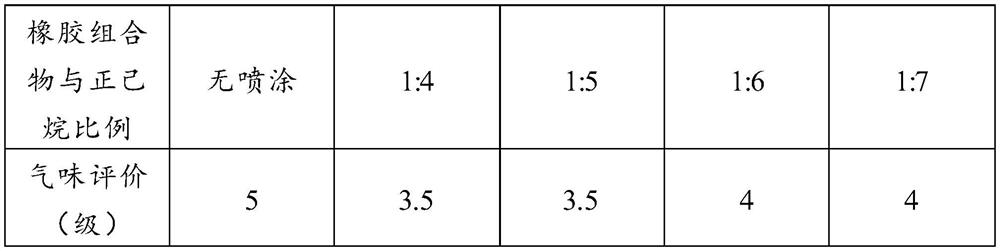

[0048] Dissolve the above-mentioned rubber composition in n-hexane according to several different weight ratios, and after stirring evenly, take about 70 g of the obtaine...

Embodiment 2-3

[0053] According to the components and their proportions shown in Table 1, rubber compositions were obtained by using the mixing method in Example 1.

[0054] Dissolve the above rubber composition in n-hexane at a weight ratio of 1:4, stir evenly, take about 70 g of the obtained rubber mixed solution, and spray it evenly on the unvulcanized raw tire, and then let it stand for 30 minutes . Vulcanize the raw tires after standing still according to the set conditions to obtain low-odor tires.

[0055] According to the above-mentioned method, 15 people were invited to evaluate the low-odor tires respectively, and the median average was taken. The results are shown in Table 3.

[0056] The overall tire odor evaluation result of table 3 embodiment 1-3

[0057] Example 1 2 3 odor level 3.5 3.5 3.5

[0058] It can be seen from the above examples that the present invention effectively reduces tire odor without changing the existing formulation and manufactur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com