Condensed milk powder and its wet preparation process

A technology of condensed milk powder and wet process is applied in the field of condensed milk powder and its wet process preparation technology, which can solve the problems of elevated triglyceride low-density lipoprotein, hidden dangers to consumers' health, short shelf life, and the like, so as to improve gastrointestinal function and Metabolism, inhibiting the growth of harmful bacteria, and long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

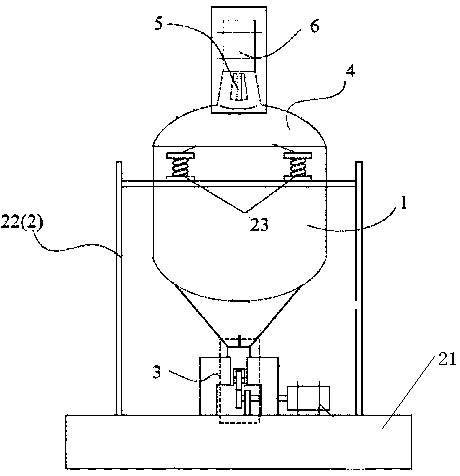

Image

Examples

Embodiment 1

[0025] The condensed milk powder is characterized in that it comprises the following components in weight percentage: 40% glucose syrup, 28% coconut oil, 10% fructose, 10% milk powder, 6% sodium caseinate, 0.3% silicon dioxide, dihydrogen phosphate Potassium 1%, sodium tripolyphosphate 0.3%, mono-diglyceride fatty acid ester 0.5%, sodium stearoyl lactylate 0.3%, food flavor 0.2%.

[0026] The present invention also provides the wet method preparation technique of above-mentioned condensed milk powder, it is characterized in that: it is made up of following steps:

[0027] (1) Weigh 0.3% sodium tripolyphosphate, 1% dipotassium hydrogen phosphate, 10% milk powder, 6% sodium caseinate raw materials, and put the raw materials and 50°C purified water into the mixing tank in a ratio of 1:2 Dissolve, the dissolution time is 5min, 5min, 14min, 14min in turn, after all the materials are dissolved, the water temperature is increased to 65°C, and the sodium tripolyphosphate, dipotassium ...

Embodiment 2

[0032] The condensed milk powder is characterized in that it includes the following components in weight percentage: 40% glucose syrup, 25% coconut oil, 15% fructose, 13% milk powder, 3% sodium caseinate, 0.5% silicon dioxide, dihydrogen phosphate Potassium 1.5%, sodium tripolyphosphate 0.5%, mono-diglyceride fatty acid ester 0.5%, sodium stearoyl lactylate 0.4%, food flavor 0.3%.

[0033] The present invention also provides the wet method preparation technique of above-mentioned condensed milk powder, it is characterized in that: it is made up of following steps:

[0034](1) Weigh 0.5% sodium tripolyphosphate, 1.5% dipotassium hydrogen phosphate, 13% milk powder, and 3% sodium caseinate raw materials, and put the raw materials and 50°C purified water into the mixing tank in a ratio of 1:2 Dissolve, the dissolution time is 5min, 5min, 12min, 18min in turn, after all the materials are dissolved, the water temperature is increased to 65°C, and the sodium tripolyphosphate, dipota...

Embodiment 3

[0039] The condensed milk powder is characterized in that it comprises the following components by weight percentage: 40% of glucose syrup, 25% of coconut oil, 12% of fructose, 15% of milk powder, 4% of sodium caseinate, 0.6% of silicon dioxide, dihydrogen phosphate Potassium 1%, sodium tripolyphosphate 0.6%, mono-diglyceride fatty acid ester 0.5%, sodium stearoyl lactylate 0.5%, food flavor 0.3%.

[0040] The present invention also provides the wet method preparation technique of above-mentioned condensed milk powder, it is characterized in that: it is made up of following steps:

[0041] (1) Weigh 0.6% sodium tripolyphosphate, 1% dipotassium hydrogen phosphate, 15% milk powder, and 4% sodium caseinate raw materials, and put the raw materials and 50°C purified water into the mixing tank in a ratio of 1:2 Dissolve, the dissolution time is 5min, 5min, 15min, 18min in turn, after all the materials are dissolved, the water temperature is increased to 65°C, and the sodium tripolyp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com