Assembling method for zero-carbon attendance sentry box used for construction site

A technology for zero-carbon attendance booths and construction sites, which is applied in the direction of buildings, small buildings, and building types, and can solve problems such as difficult to change the size of the space, affect the performance of use, increase maintenance costs, etc., and achieve strong gravity and reliable use , Improve the effect of the top pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

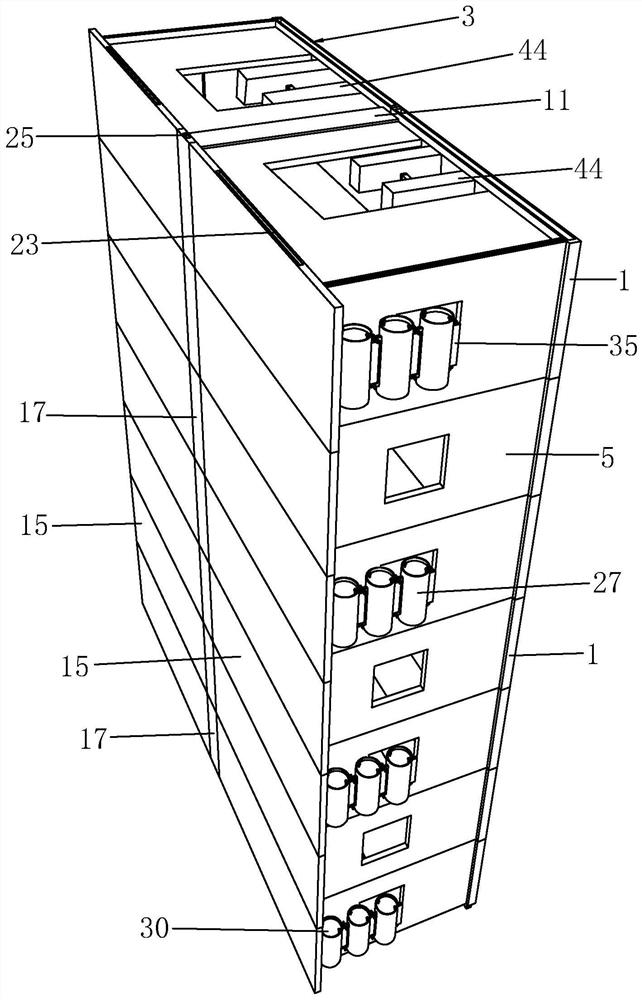

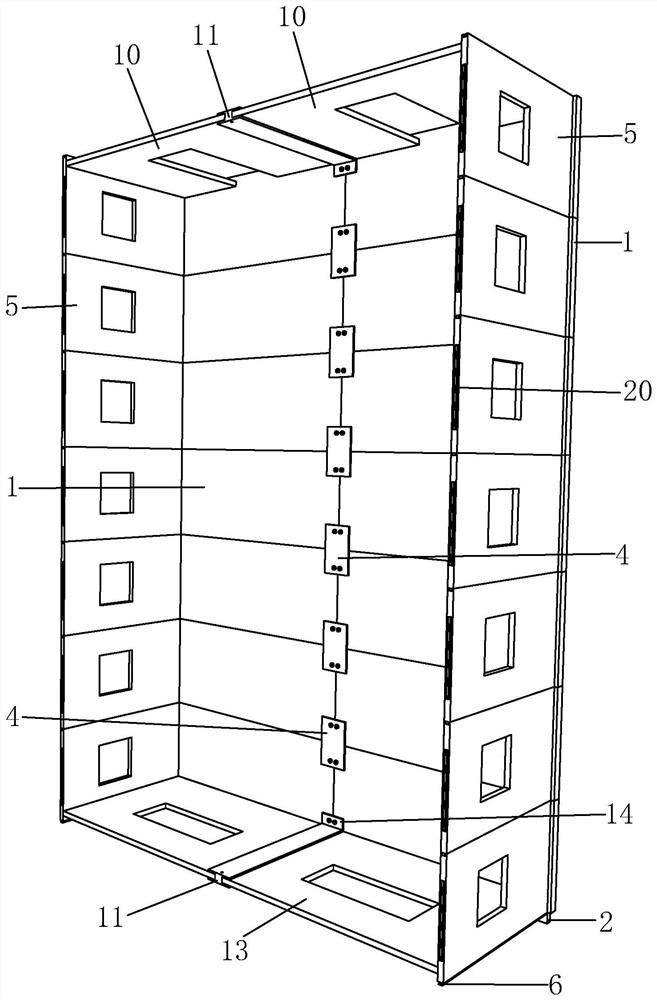

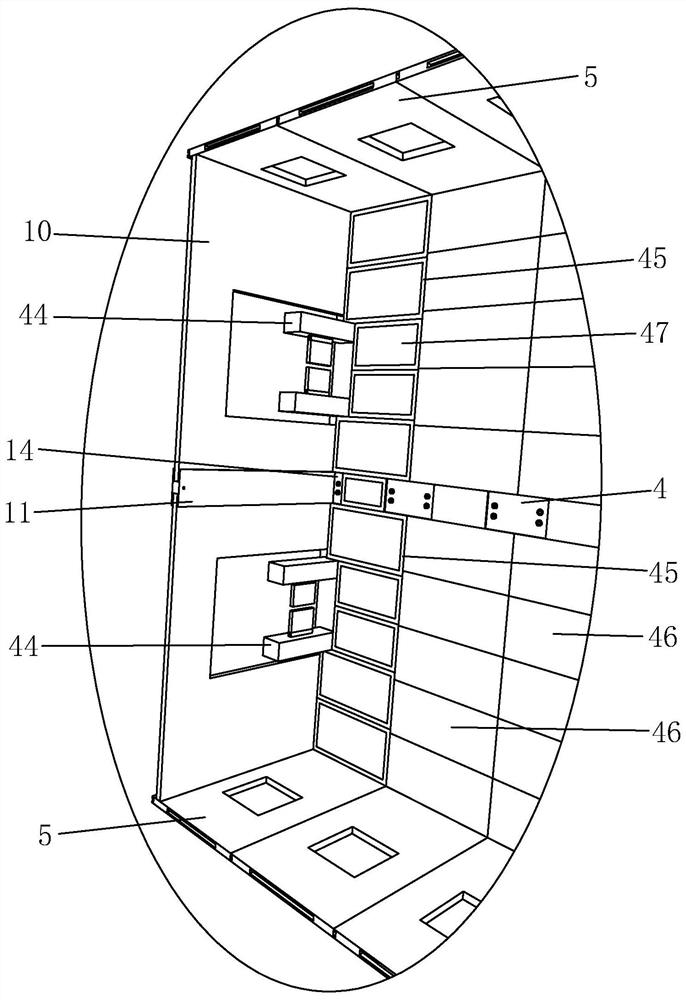

[0052] like Figure 1 to Figure 12 As shown, it is a method for assembling a construction site zero-carbon attendance booth of the present invention, which includes the following steps:

[0053] (a) Base assembly:

[0054] ⑴Insert the fixed lug 2 on one side of the last bottom plate 1 into the fixed slot 3 on the side of the previous bottom plate 1, in this way, assemble multiple bottom plates 1 into a bottom plate unit, so that the length of the bottom plate unit conforms to the design drawings Requirements, the assembly of the base plate unit is fast, the positioning is simple, the operation difficulty is low, the overall length can be changed flexibly, and the adaptability is strong.

[0055] (2) Put the two sets of bottom plate units against each other, nail the limit plate 4, connect and fix the limit plate 4 with the four adjacent bottom plates 1, and assemble the two sets of bottom plate units into one body as the floor of the attendance booth. The two groups of botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com