Double-fiber reflection type collimator and industrial equipment

A reflective and collimator technology, which is applied in the direction of instruments, light guides, optics, etc., can solve the problems of easy burning of the end face of the optical fiber, and achieve the effects of reducing power density, solving easy burning, and increasing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

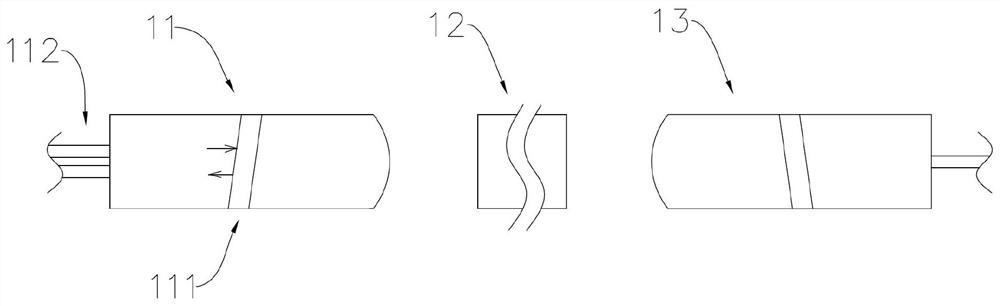

no. 1 example

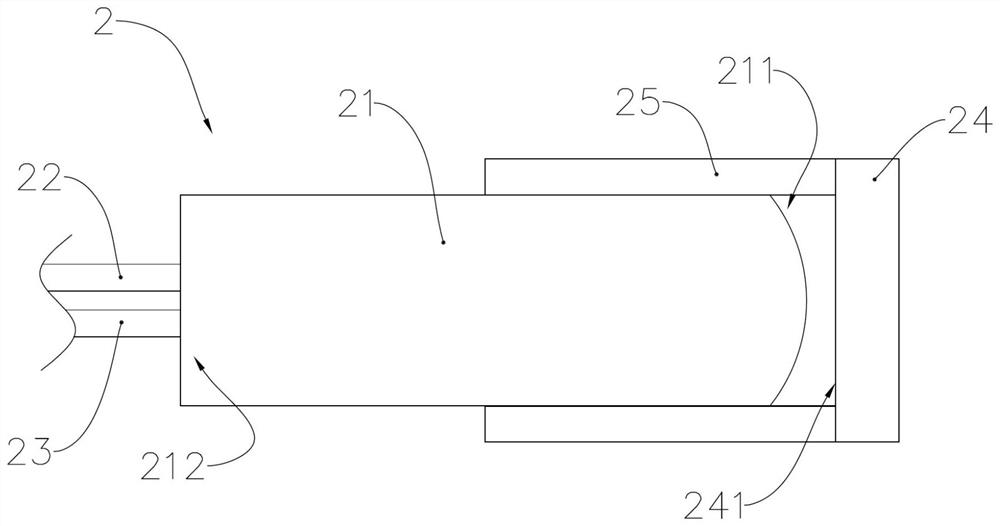

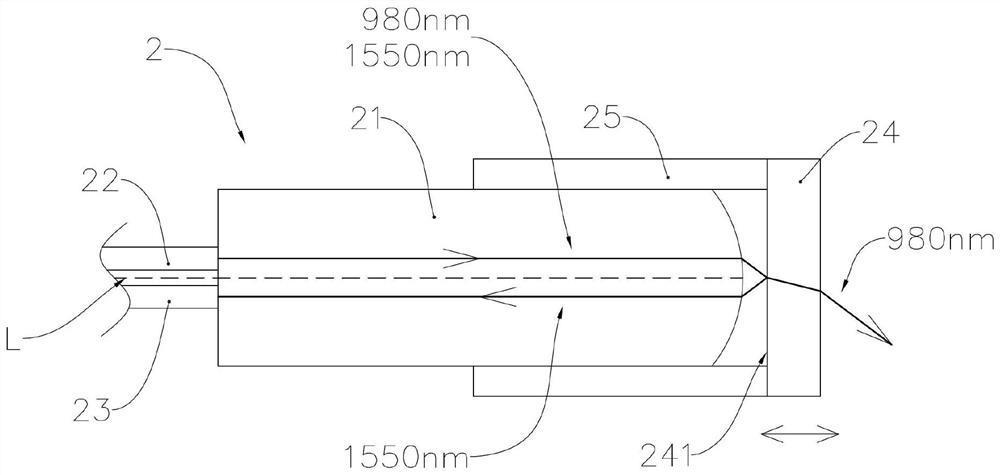

[0026] refer to figure 2 with image 3 , the dual-fiber reflective collimator includes a lens 21, a first optical fiber 22, a second optical fiber 23, a filter 24 and a sleeve 25. The lens 21 (C-LENS) can be arranged as a cylinder made of quartz, and there is no internal 8-degree slope, the inside of the lens 21 is complete, the lens 21 is provided with a first end surface 211 and a second end surface 212 at both ends of the optical path direction, the first end surface 211 is arranged in a convex spherical arc shape, and the second end surface 212 is arranged in a plane , the first optical fiber 22 and the second optical fiber 23 are welded to the second end face 212 respectively, and the first optical fiber 22 and the second optical fiber 23 are arranged symmetrically with respect to the optical axis L of the lens 21 .

[0027] The casing 25 is made of quartz or glass, and is arranged in a hollow tubular shape. The lens 21 is arranged in the casing 25, and the filter 24 is...

no. 2 example

[0031] refer to Figure 5 , the dual-fiber reflective collimator includes a self-focusing lens 31, a first optical fiber 32, a second optical fiber 33, and a filter 34. The self-focusing lens 31 (G-LENS) can be arranged in a cylinder made of quartz, and the self-focusing lens The inside of 31 is complete, lens 31 is respectively provided with first end face 311 and second end face 312 at the two ends of optical path direction, the end faces of two planes are all perpendicular to the optical axis of self-focusing lens 31, and first optical fiber 32 and second The optical fibers 33 are respectively fused with the second end face 312, and a first capillary 321 is provided outside the core of the first optical fiber 32, a second capillary 331 is provided outside the core of the second optical fiber 33, the first capillary 321 and the second capillary 331 They are welded to the second end face 312 respectively, and the first optical fiber 22 and the second optical fiber 23 are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com