Closed self-circulation cooling submersible sewage pump

A self-circulation, sewage pump technology, applied in non-variable-capacity pumps, non-displacement pumps, pumps, etc., can solve the problems of water volume affecting cooling, easy blockage of cooling channels, disadvantage, etc., to reduce after-sales costs and improve operation. Efficiency and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions in the embodiments of the present invention will be clearly and completely described below.

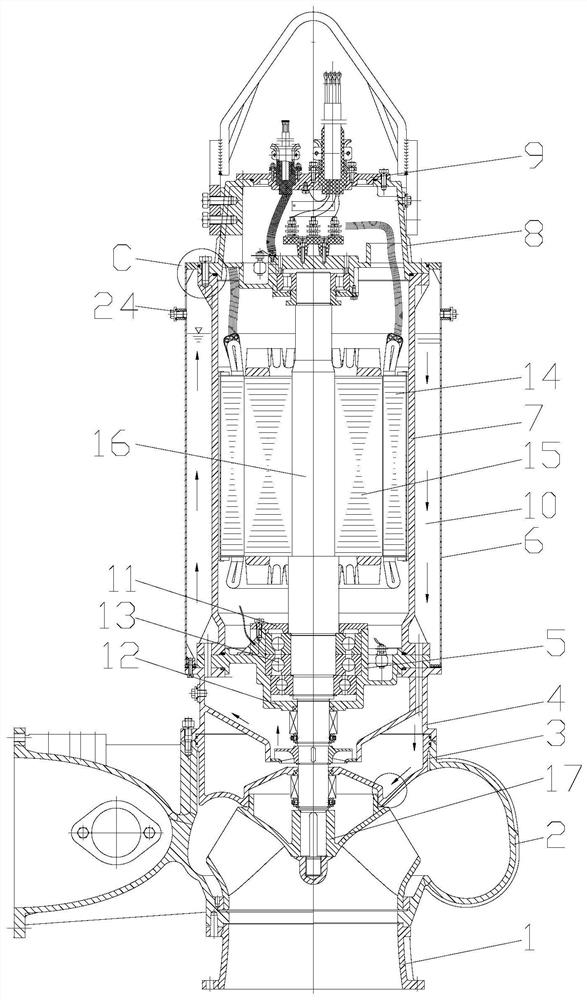

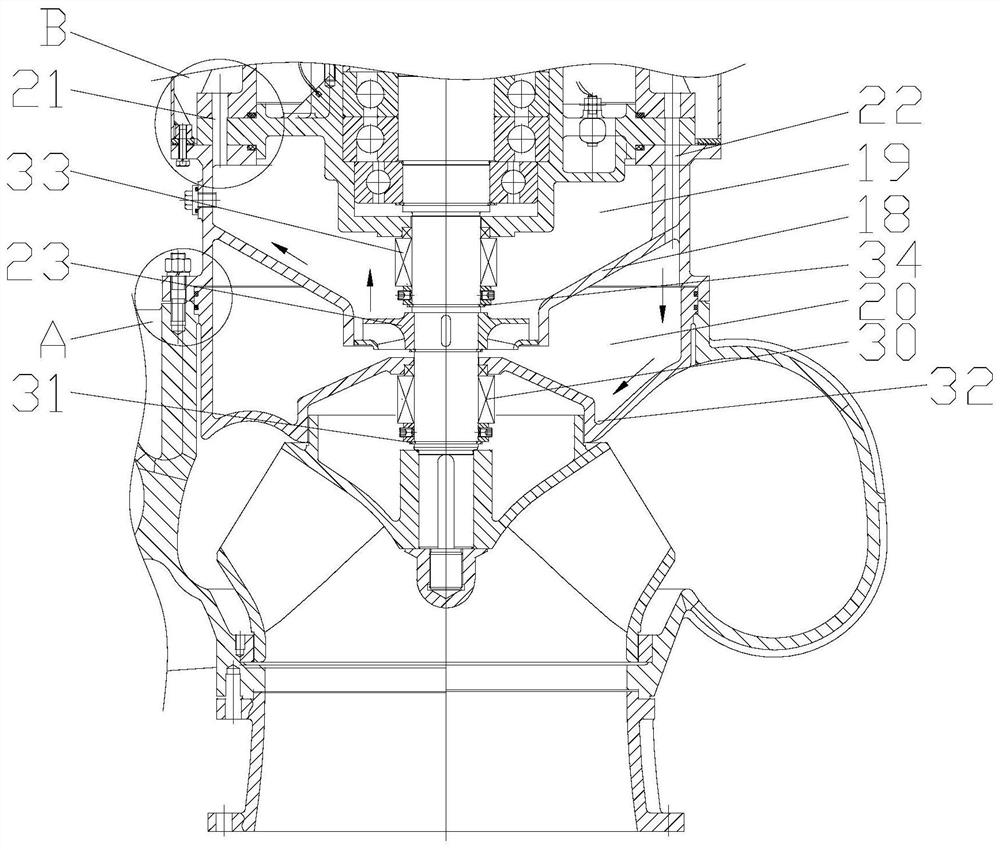

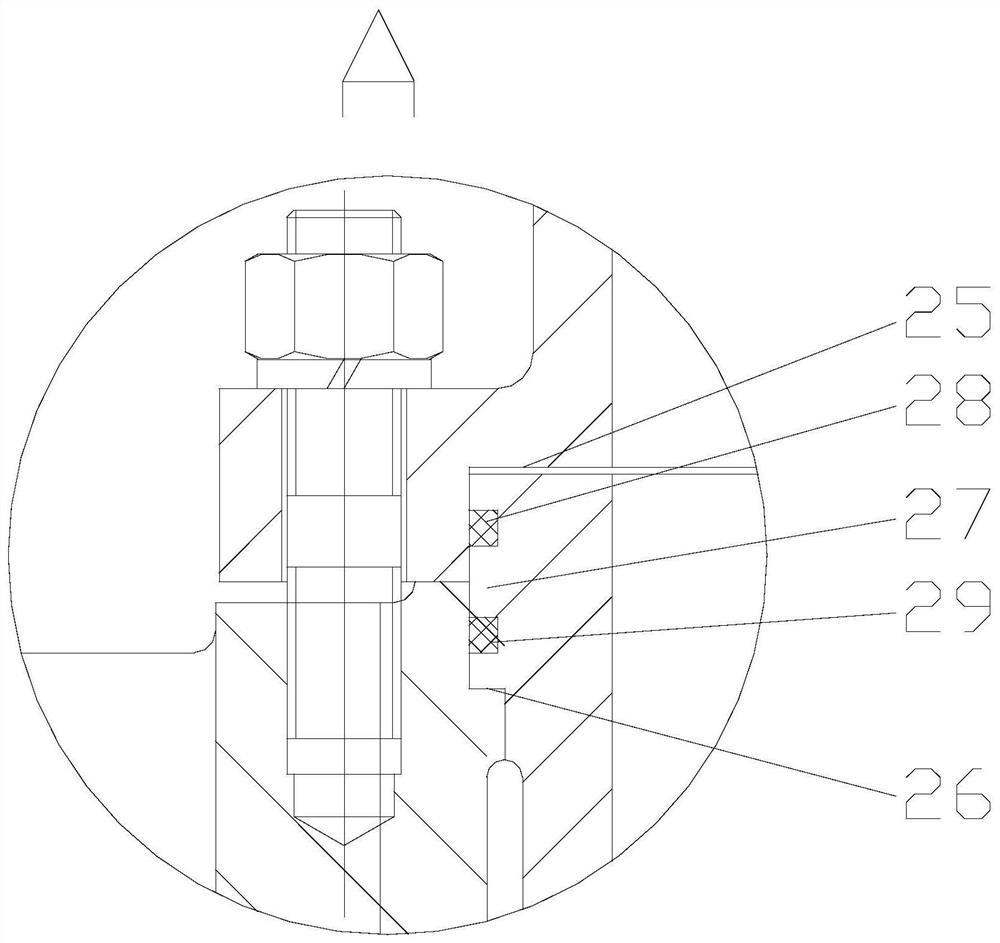

[0026] Such as Figure 1~5 As shown, a closed self-circulating cooling submersible sewage pump includes a pump base 1, a pump body 2, a pump cover 3, a connecting seat 4, a bearing seat 5, a cooling shell 6, a motor shell 7, an upper end cover 8 and a junction box Cover 9, the bottom and top of the pump base 1 are respectively provided with a lower flange installation surface and an upper flange installation surface, and the lower flange installation surface is used to connect with the installation base; the bottom of the pump body 2 is connected with the pump base The upper flange mounting surface of 1 is connected; the pump cover 3 is connected in the pump body 2; the connecting seat 4, the cooling shell 6 and the upper end cover 8 are sequentially connected above the pump body 2; the bearing seat 5 is located at the connecting Above the seat 4; the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com