Array substrate and touch display panel

A technology of array substrates and touch electrodes, applied in instruments, semiconductor devices, computing, etc., can solve the problems of touch stripes on touch display panels and affect testing, so that the sensing area is not affected and the problem of stripes is avoided Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

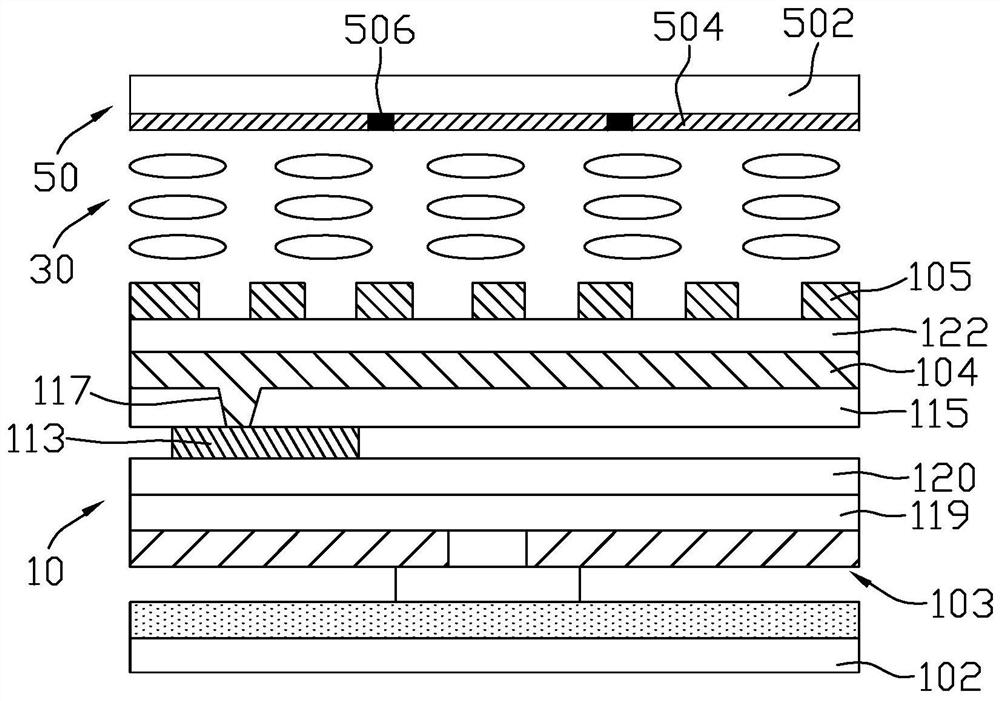

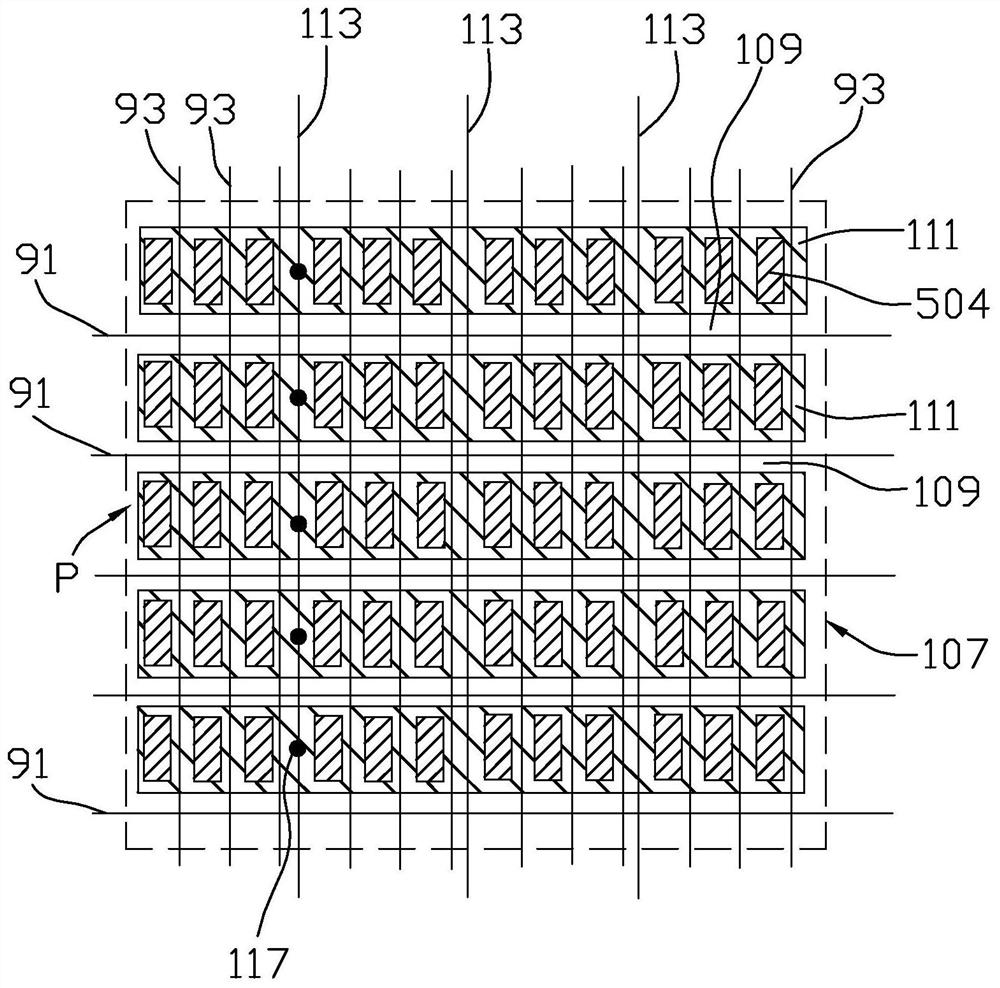

[0024] figure 1 It is a schematic cross-sectional structure diagram of a touch display panel according to an embodiment of the present invention. Please refer to figure 1 The touch display panel provided in this embodiment includes an array substrate 10 , a liquid crystal layer 30 and an opposite substrate 50 , and the liquid crystal layer 30 is located between the array substrate 10 and the opposite substrate 50 . The array substrate 10 includes a first substrate 102, a switching element 103, a common electrode 104 and a pixel electrode 105, the switching element 103, the common electrode 104 and the pixel electrode 105 are stacked on the first substrate 102, and the common electrode 104 and the pixel electrode 105 are stacked on the first substrate 102. 105 insulation interval settings. Please refer to figure 2 , the common electrode 104 is divided into a plurality of touch electrodes 107 to realize the touch function. Please refer to image 3 , a plurality of pixel uni...

no. 2 example

[0037] Please refer to Figure 4, the structure of the touch display panel of this embodiment is basically the same as that of the touch display panel of the first embodiment, the difference is that in this embodiment, the sub-electrodes 111 of the same touch electrode 107 are connected to the The adjacent sub-electrodes 111 are electrically connected, and one touch electrode 107 only needs to pass through one via hole 117 to be electrically connected to the touch signal line 113 , without each sub-electrode 111 passing through one via hole 117 and the touch signal line respectively. 113 is electrically connected, which can greatly reduce the number of openings 117 and simplify the manufacturing process.

[0038] Specifically, the connection portion 124 is provided corresponding to the position of the data line 93 , that is, corresponding to the position of the light shielding layer 506 of the opposite substrate 50 .

[0039] Specifically, the connecting portion 124 may be di...

no. 3 example

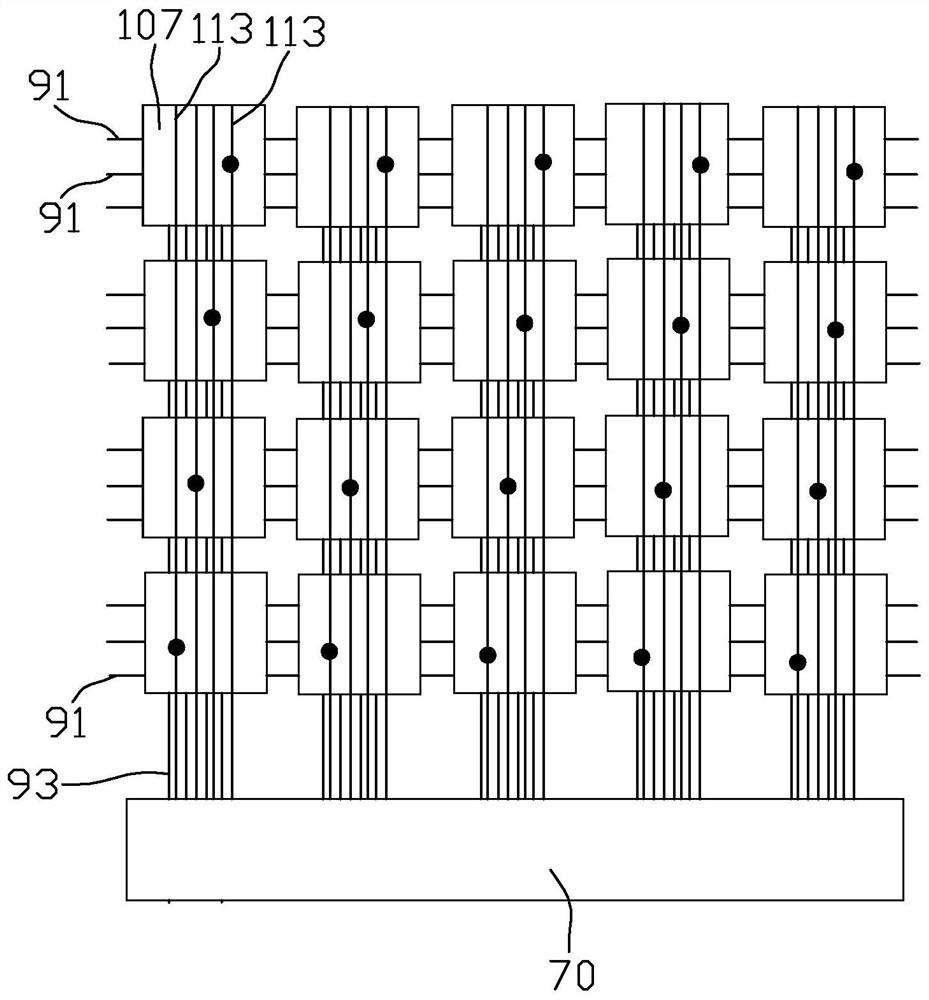

[0041] Please refer to Figure 5 The structure of the touch display panel of this embodiment is basically the same as that of the touch display panel of the first embodiment. The difference is that in this embodiment, two scan lines 91 are arranged every two rows of pixel units P, which are located above The scanning line 91 of the upper part is connected to the switching element 103 in the upper pixel unit P, and the lower scanning line 91 is connected to the switching element 103 in the lower pixel unit P. Each sub-electrode 111 is provided corresponding to the pixel units P in two rows. In this way, the number of hollows 109 on each touch electrode 107 can be reduced, which simplifies the manufacturing process and increases the sensing area of the touch electrode 107 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com