A Fast, Accurate, and Multi-Dimensional Evaluation Method for Liquid Level Fluctuation in the Mold of Continuous Casting Machines

A liquid level fluctuation and evaluation method technology, which is applied to the program control, instrument, program control and other directions in the sequence/logic controller, can solve the problems of insufficient accuracy and achieve the effect of reducing the quality loss of finished products and reducing quality loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

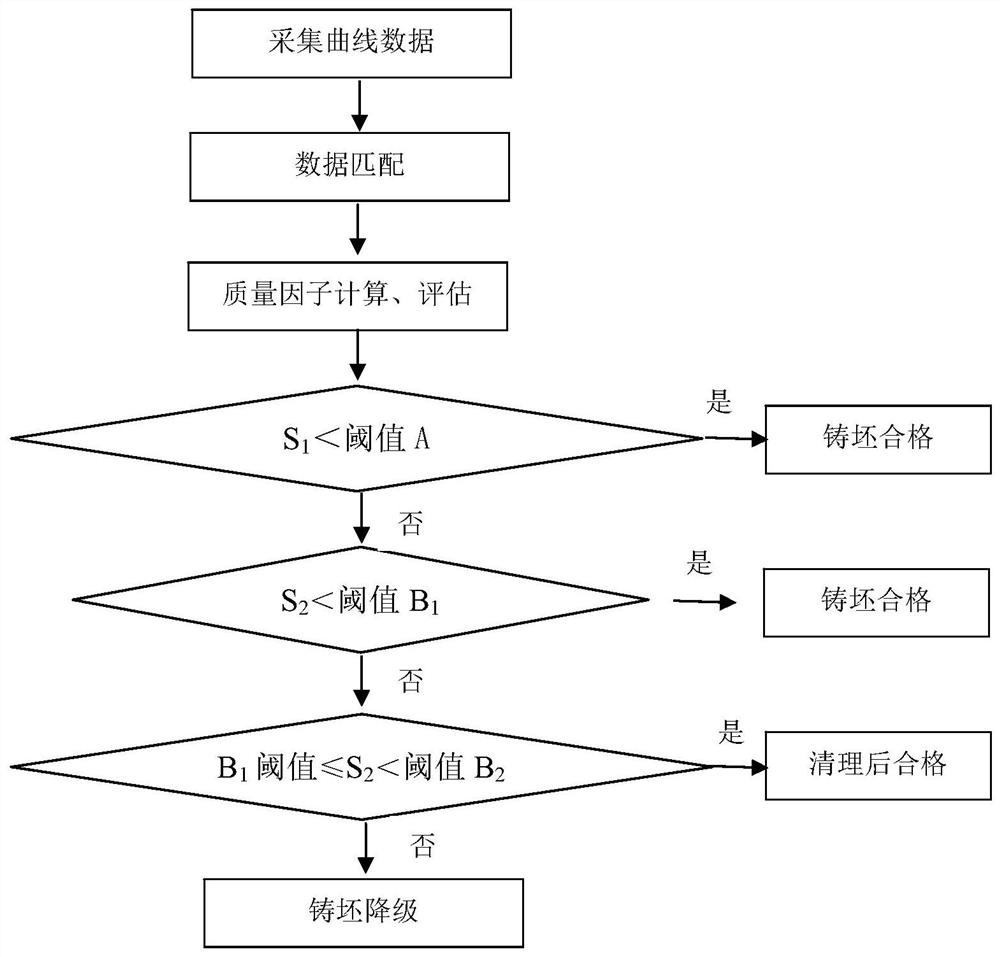

[0040] The traditional method of evaluating mold liquid level fluctuations is to evaluate the mold liquid level fluctuations of pouring times and heats, which will result in downgrading treatment of cast slabs with normal mold liquid level fluctuations, resulting in quality loss; and the liquid level of each slab It is difficult to evaluate the severity of surface fluctuations, and disposal according to uniform standards will lead to an increase in billet disposal costs. However, in this embodiment, a fast, accurate, and multi-dimensional continuous casting machine crystallizer liquid level fluctuation evaluation method accurately matches the crystallizer liquid level fluctuation curve to the specific slab, so as to realize the accurate evaluation of the crystallization of each slab. Fluctuation of the liquid level of the device is beneficial to the subsequent disposal of the slab and the quality tracking in the subsequent process, reducing the quality loss of the slab and the ...

Embodiment 2

[0056] A fast, accurate, and multi-dimensional continuous casting machine crystallizer liquid level fluctuation evaluation method of this embodiment is basically the same as that of Embodiment 1, the difference is that the second-level PCS module in step (2) adopts the Oracle database method to store.

[0057] Unqualified proportional quality factor S of liquid level fluctuation in slab crystallizer 1 : Obtain the total number of points of the liquid level fluctuation deviation curve of the slab mold, expressed as ±X 1 mm is used as the standard for evaluating the liquid level fluctuation of the slab mold, where X 1 The range is (3-10) mm, specifically, X in this embodiment 1 is 5, and the deviation curve of the liquid level fluctuation of the cast slab exceeds ±X 1 The points in mm are unqualified points, and the ratio of unqualified points obtained by using unqualified points / total points is the unqualified proportion quality factor of liquid level fluctuation.

[0058] ...

Embodiment 3

[0067] A fast, accurate and multi-dimensional continuous casting machine crystallizer liquid level fluctuation evaluation method in this embodiment is basically the same as in Embodiment 1, the difference is that the unqualified proportion quality factor S of the billet crystallizer liquid level fluctuation 1 : Obtain the total number of points of the liquid level fluctuation deviation curve of the slab mold, expressed as ±X 1 mm is used as the standard for evaluating the liquid level fluctuation of the slab mold, where X 1 The range is (3-10) mm, specifically, X in this embodiment 1 is 10, and the deviation curve of the liquid level fluctuation of the cast slab exceeds ±X 1 The points in mm are unqualified points, and the ratio of unqualified points obtained by using unqualified points / total points is the unqualified proportion quality factor of liquid level fluctuation.

[0068] Also include step (6) slab quality assessment, disposal in the present embodiment:

[0069] Ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com