Along-surface flashover vacuum trigger switch with gear-shaped trigger electrode structure

A surface flashover and trigger electrode technology, which is applied to electric switches, high voltage/high current switches, circuits, etc., can solve the problems of short distance between the trigger electrode and the main gap arc, ablation and carbonization of the surface of the flashover material, and affecting the life of the switch. , to reduce the risk of arc ablation, prolong life, and accelerate the conduction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

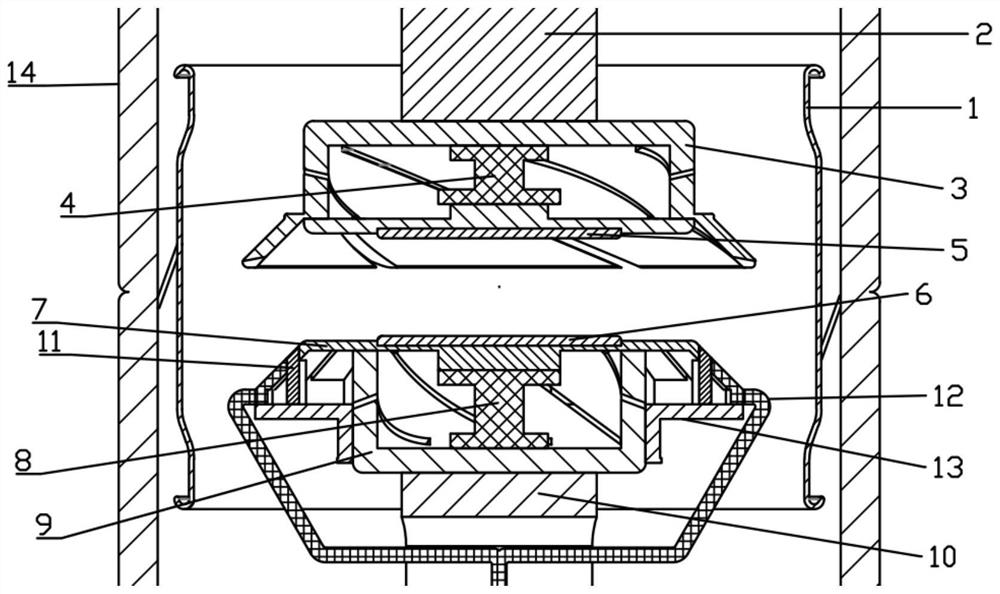

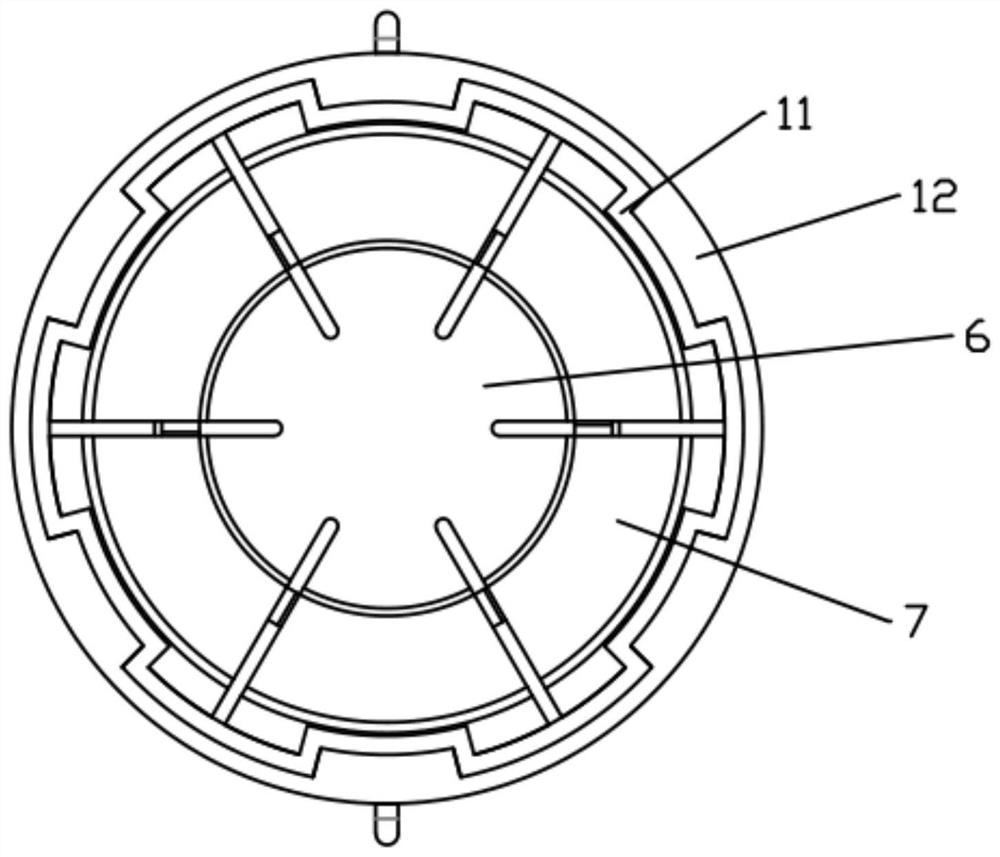

[0023] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0024] to combine figure 1 , a surface flashover vacuum trigger switch with a "gear-shaped" trigger electrode structure, including an anode electrode, a cathode electrode, a surface flashover material and a trigger electrode.

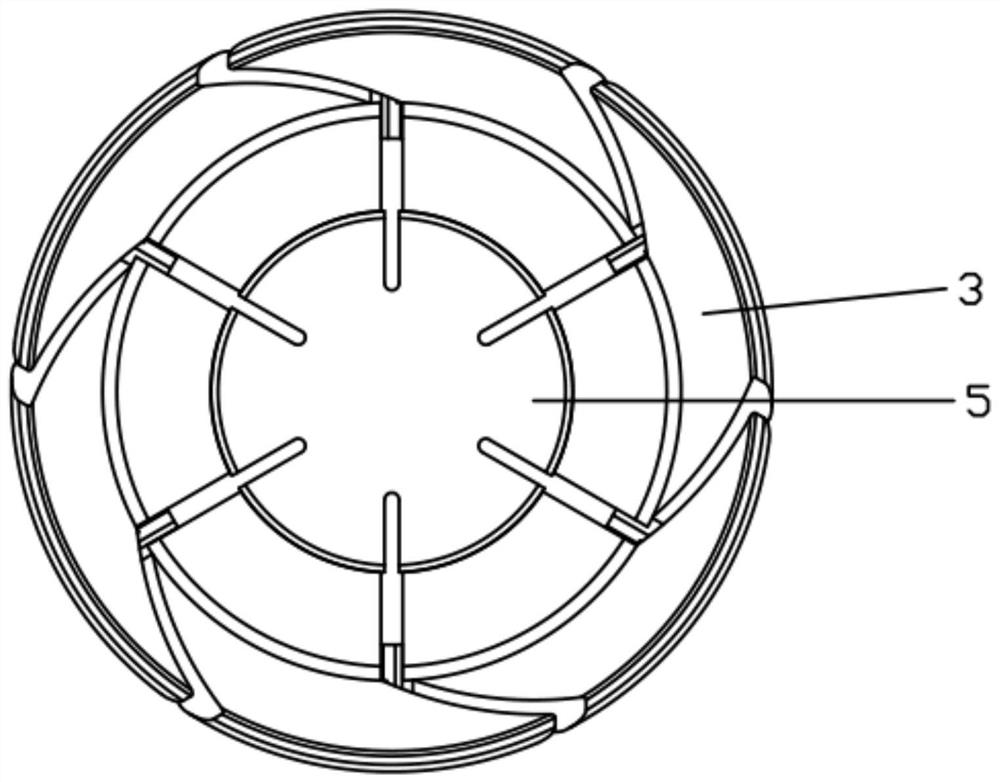

[0025] The anode electrode includes an anode conductive rod 2 , an anode outwardly expanding longitudinal magnetic electrode cup 3 and an anode electrode disk 5 .

[0026] The anode outward expansion type longitudinal magnetic electrode cup 3 is fixed on the upper part of the anode conductive rod 2, and its expansion area extends obliquely outward from the traditional longitudinal magnetic electrode cup structure. turn-on speed.

[0027] The anode electrode disk 5 is fixed in the shallow groove at the center of the anode outwardly expanding longitudinal magnetic electrode cup 3 .

[0028] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com