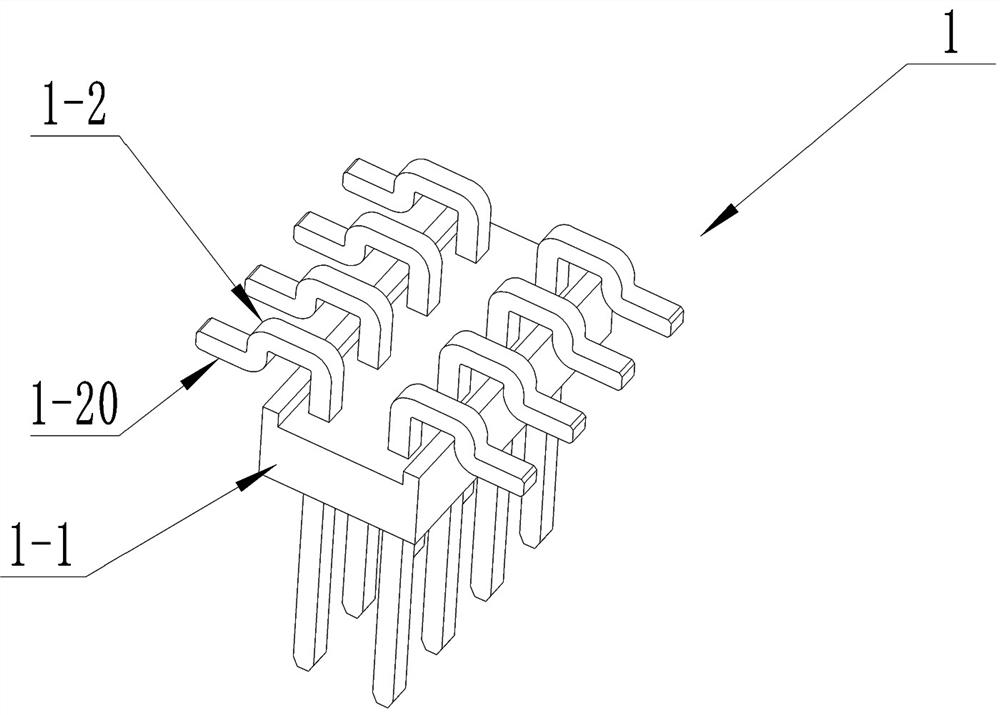

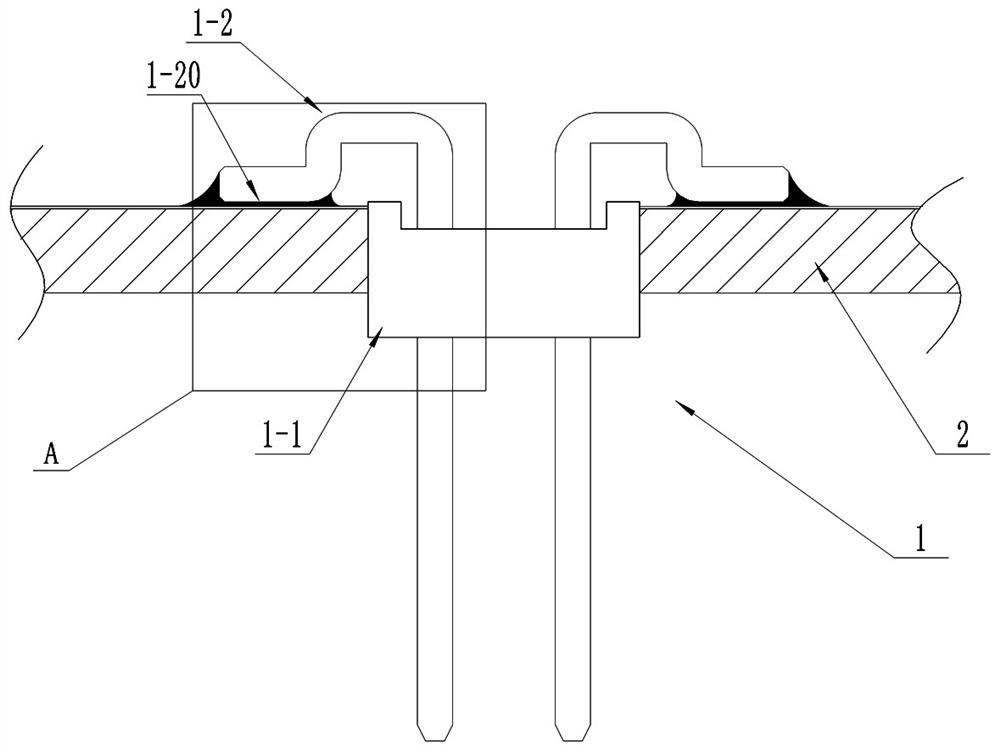

Patch double pin header and double female header for metal substrate

A metal substrate, double-row needle technology, applied in the direction of fixed connection, contact parts, electrical components, etc., can solve the problems of labor-hours, low work efficiency, joint damage to the thermal insulation layer, etc., to improve work efficiency and reliable circuit connection. , to avoid the effect of short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

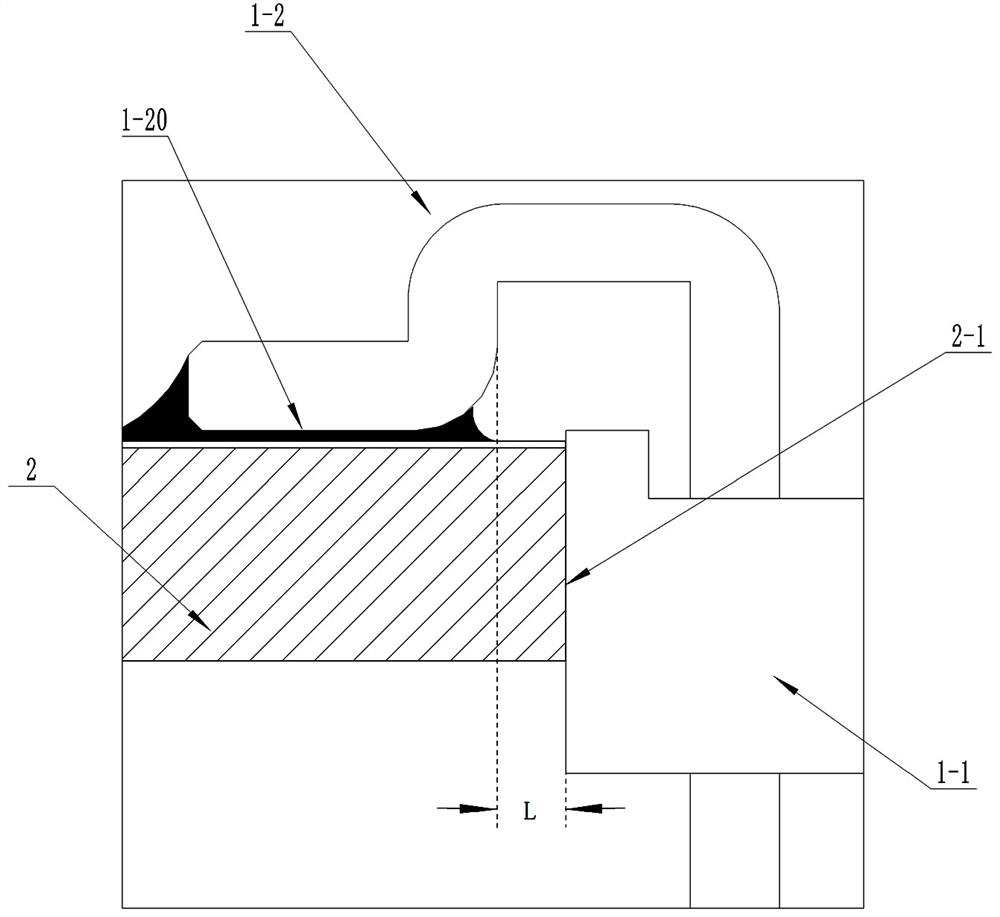

Embodiment 1

[0027] The first embodiment is further optimized. The front, rear, left and right side walls of the insulating body are flat and have no grooves. The side wall surfaces of the prior art pin header insulating body have grooves that are easy to divide. In this embodiment, the grooves are removed. After the groove, it is convenient to process and manufacture the insulating body and the hole of the metal substrate, and prevent the adverse consequences of liquid leakage when the front of the metal substrate needs to be filled with glue.

[0028] see Figure 4 , Figure 4 Shown is the front view of the patch double pin header for the metal substrate according to the second embodiment of the present invention. The difference between the second embodiment and the first embodiment is the elbow, and other structures are the same. The elbow part of the second embodiment is bent twice, the first bend is folded outward and downward, and the second bend is folded horizontally outward, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com