Solid rotor structure of asynchronous motor

A solid rotor, asynchronous motor technology, applied in the magnetic circuit shape/style/structure, magnetic circuit rotating parts and other directions, can solve the problems of difficult application of solid rotors and difficult process, and achieve good installation manufacturability and process realization. Simple, isolated effect from the external environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

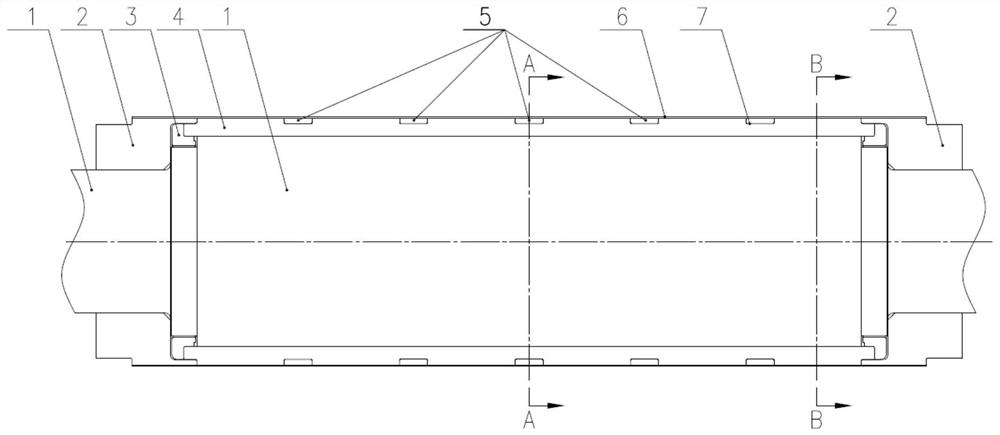

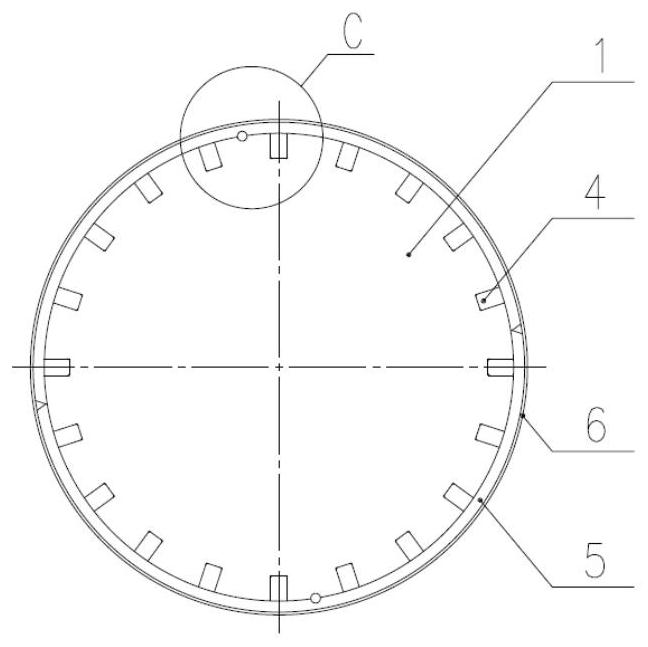

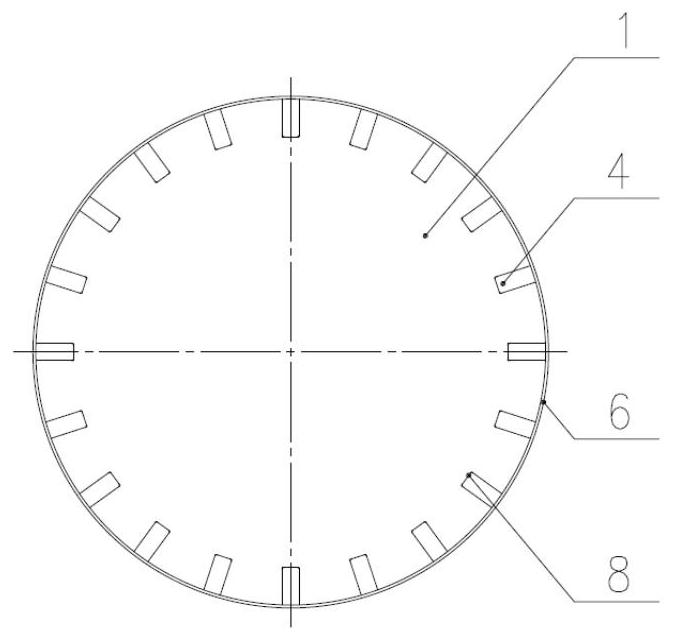

[0016] Such as figure 1 As shown, a solid rotor structure of an asynchronous motor is composed of a rotor body 1, an end ring 2, a connecting ring 3, a rotor guide bar 4, a snap ring clamping structure 5, a sleeve 6 and an elastic cylindrical pin 9, and the rotor guide bar 4 Installed in the open guide bar groove 8 of the rotor body 1, the end of the squirrel cage structure formed by welding the connecting ring 3 and the rotor guide bar 4 is provided with an end ring 2, and the inner circular surface of the end ring 2 is connected with the outer circular surface of the end of the squirrel cage structure. The matching method is interference fit, and there are multiple embedded snap ring clamping structures 5 along the axial direction of the rotor body 1, such as figure 2 As shown, an elastic cylindrical pin 9 is arranged between the clamping structure 5 and the rotor body 1 to limit the position in the circumferential direction, and the rotor body 1, the rotor guide bar 4, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com