Systems, methods, and apparatus to preheat welding wire

A technology of preheating control and preheating voltage, used in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problem of not providing electrode heating solutions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

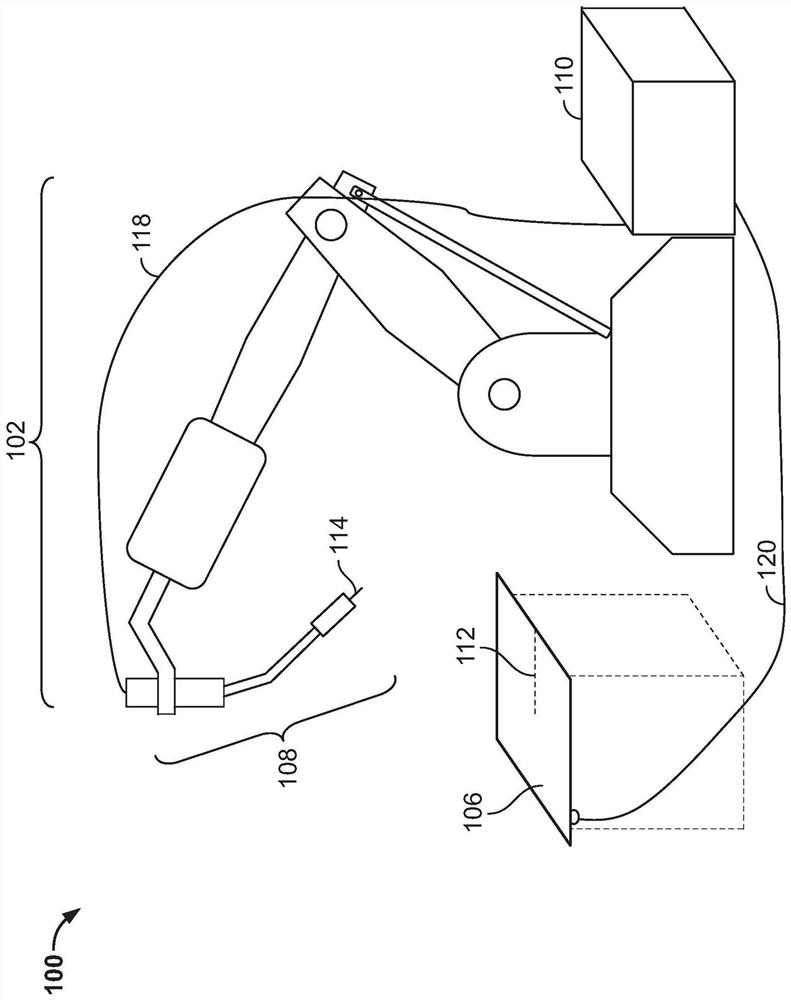

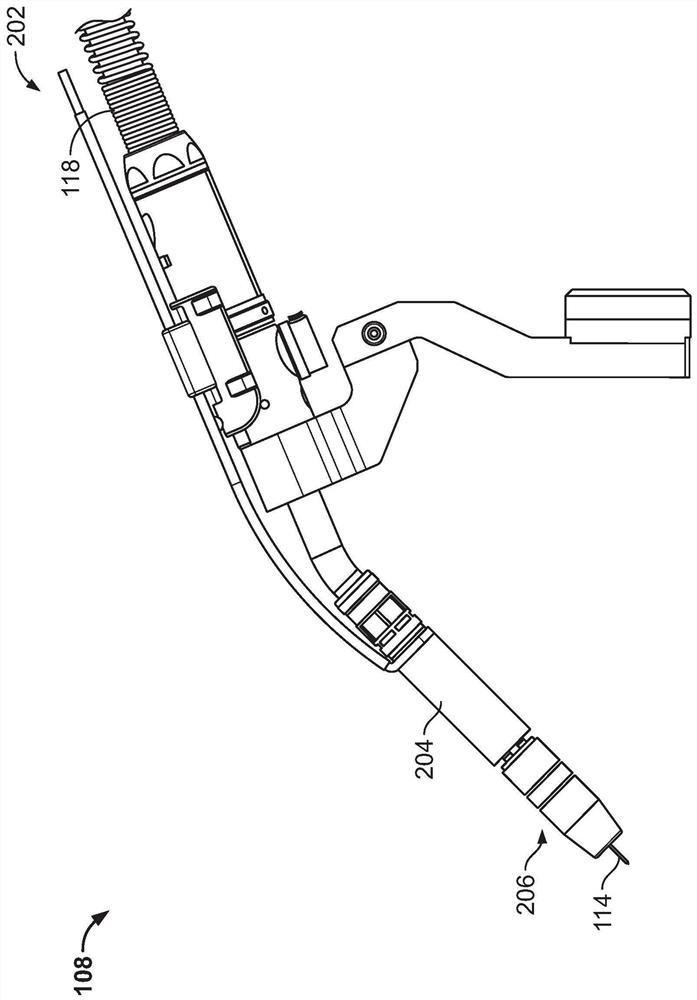

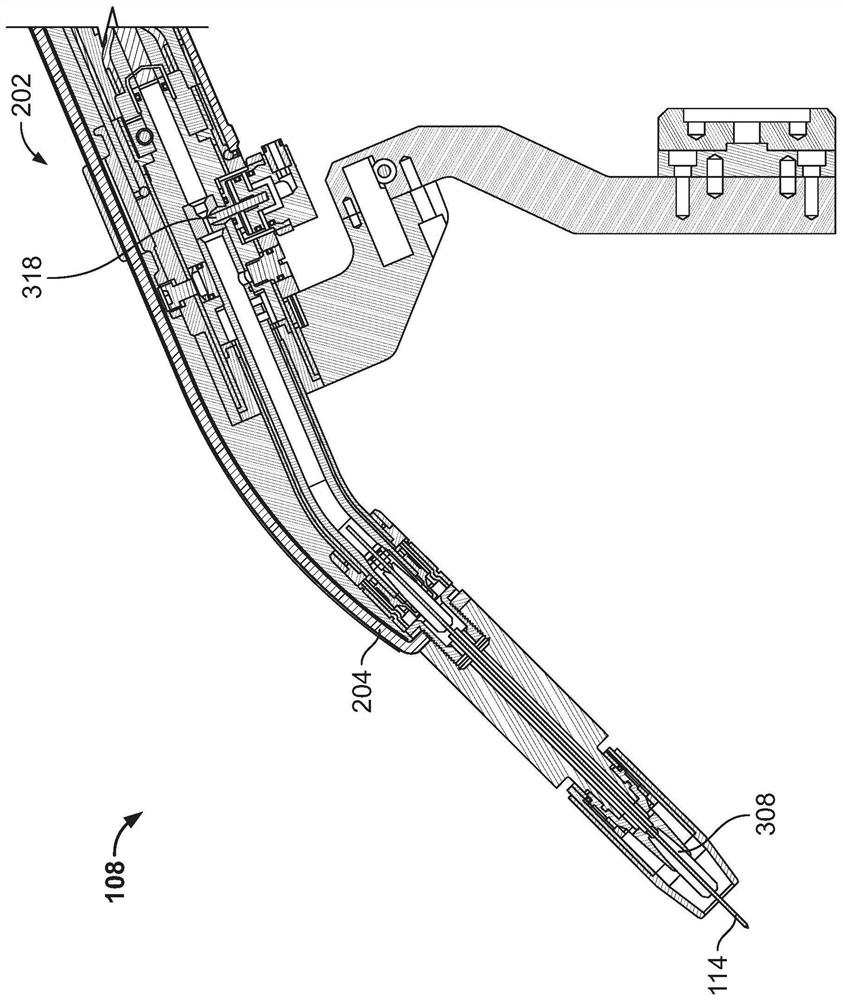

[0062] The present invention relates to a system, method and apparatus for preheating a welding wire electrode. Preferred embodiments of the present invention are described herein in detail with reference to the following drawings. The same reference numbers are used throughout the drawings to depict like or analogous elements.

[0063] To promote an understanding of the principles of the claimed technology, and to present its presently understood best mode of operation, reference will now be made to the embodiments illustrated in the drawings and specific language will be used to describe the same. It should be understood, however, that this is not intended to limit the scope of the claimed technology, such alterations and further modifications in the described devices, and such other applications of the principles of the claimed technology as described herein is expected to be ordinarily within the mind of a person skilled in the art to which the claimed technology pertains...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com