Method for manufacturing metal brush roller of roller-bottom heat treatment furnace

A manufacturing method and technology of a heat treatment furnace, applied in the testing of machines/structural components, static/dynamic balance testing, measuring devices, etc., can solve the problem that furnace rollers cannot take into account wear resistance, etc., and achieve long service life and good heat The effect of permeability and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

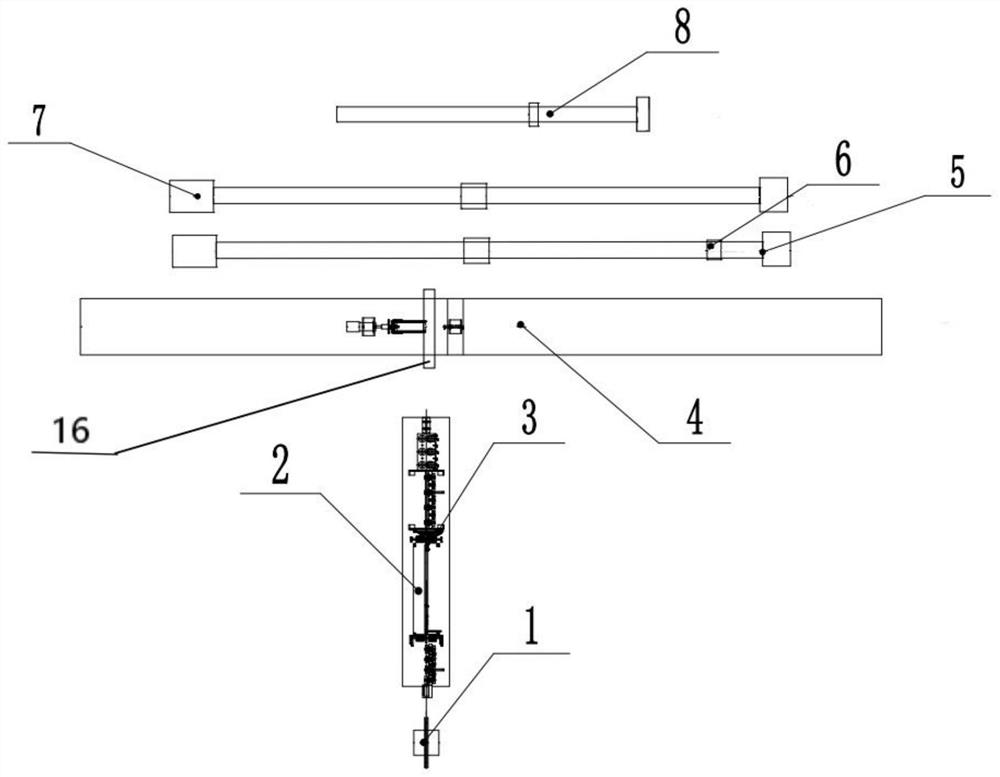

[0060] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

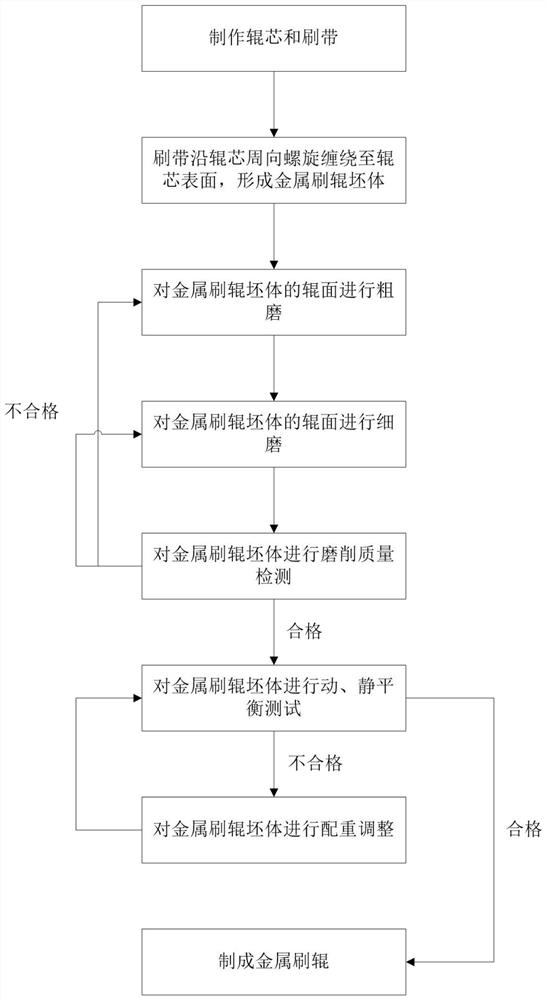

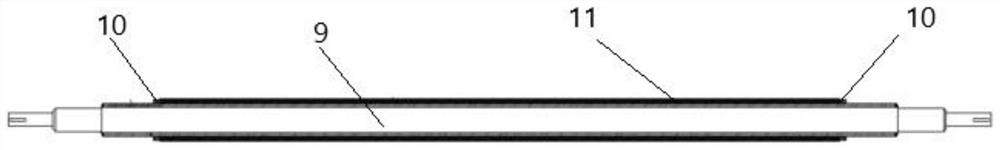

[0061] The manufacturing method of the metal brush roller of the roller hearth type heat treatment furnace proposed by the embodiment of the present invention includes the following steps: S1, making the roller core and the brush belt; Brush roller body; S3, coarse grinding of the roller surface of the metal brush roller body; S4, fine grinding of the roller surface of the metal brush roller body; S5, grinding quality inspection of the metal brush roller body; S6 1. Re-execute step S3 to step S5 or step S4 to step S5 for the metal brush body whose grinding quality is not up to standard; S7. Conduct dynamic and static balance test on the metal brush body; S8. Dynamic and static balance not up to standard The weight of the metal brush roller body is adjusted, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com